Corrosion resistant alkaline water electrolytic hydrogen-preparing apparatus container

A hydrogen production device and water electrolysis technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of inability to prevent corrosion, electrochemical corrosion, etc., and achieve the effects of low cost, elimination of corrosion, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

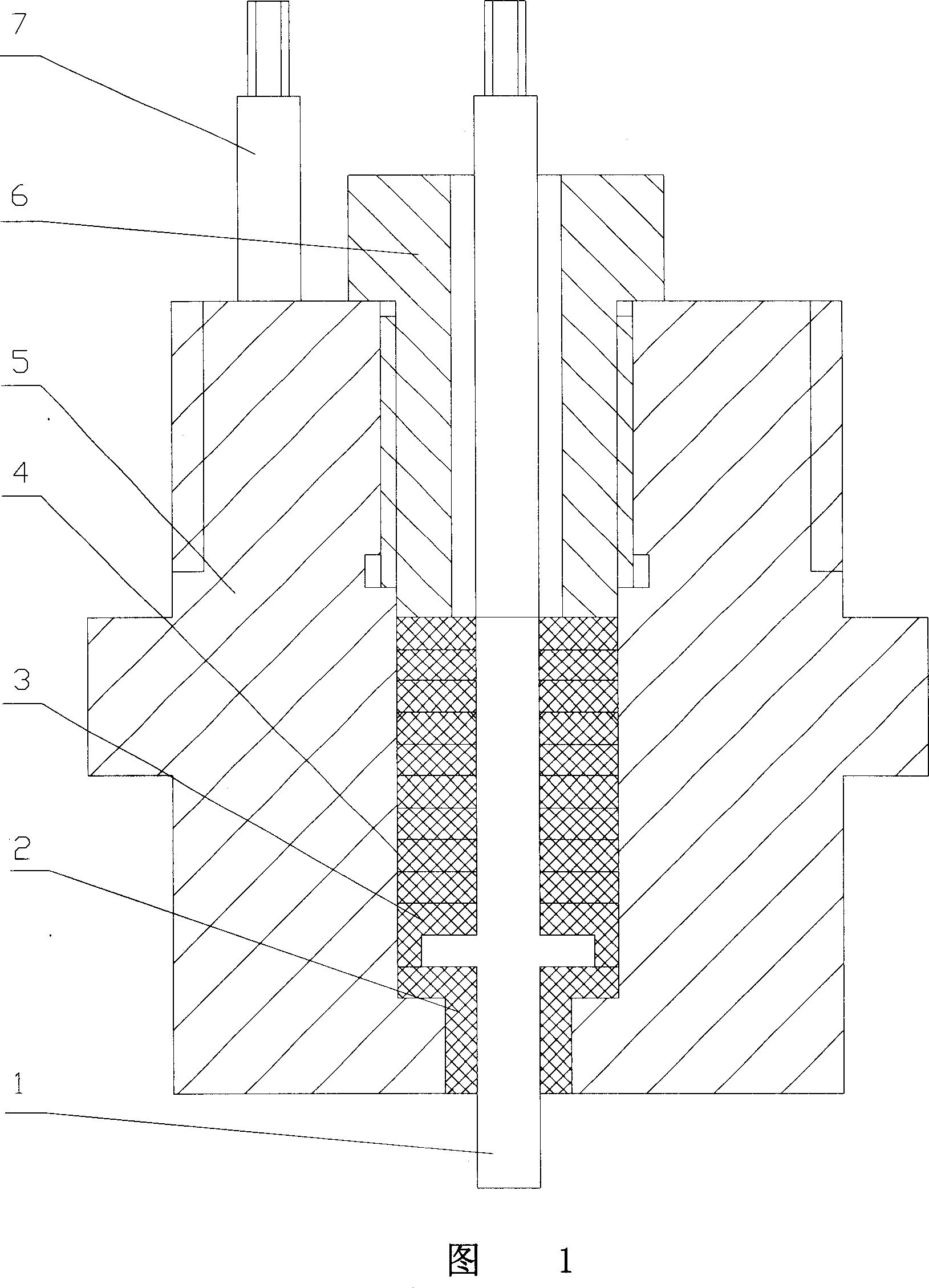

[0015] As shown in Figure 1, the anode connector is composed of an anode terminal 1, insulating mats 2, 3, 4, an anode seat 5, a compression nut 6 and a cathode terminal 7, and the anode terminal 1 can be made of the same material as the container 19 , also can adopt metals such as stainless steel, titanium, nickel to make, anode seat 5 and cathode terminal post 7 can adopt the same material making with container 19 or stainless steel making. The anode terminal 1 is tightly fixed in the anode holder through the compression nut 6 and the insulating pad 2, 3, 4, which acts as a seal under pressure to prevent. Alkali or gas leakage in the container 19, the cathode terminal 7 is welded on the anode seat 5, also can be welded on the container 19 or the pipe wall.

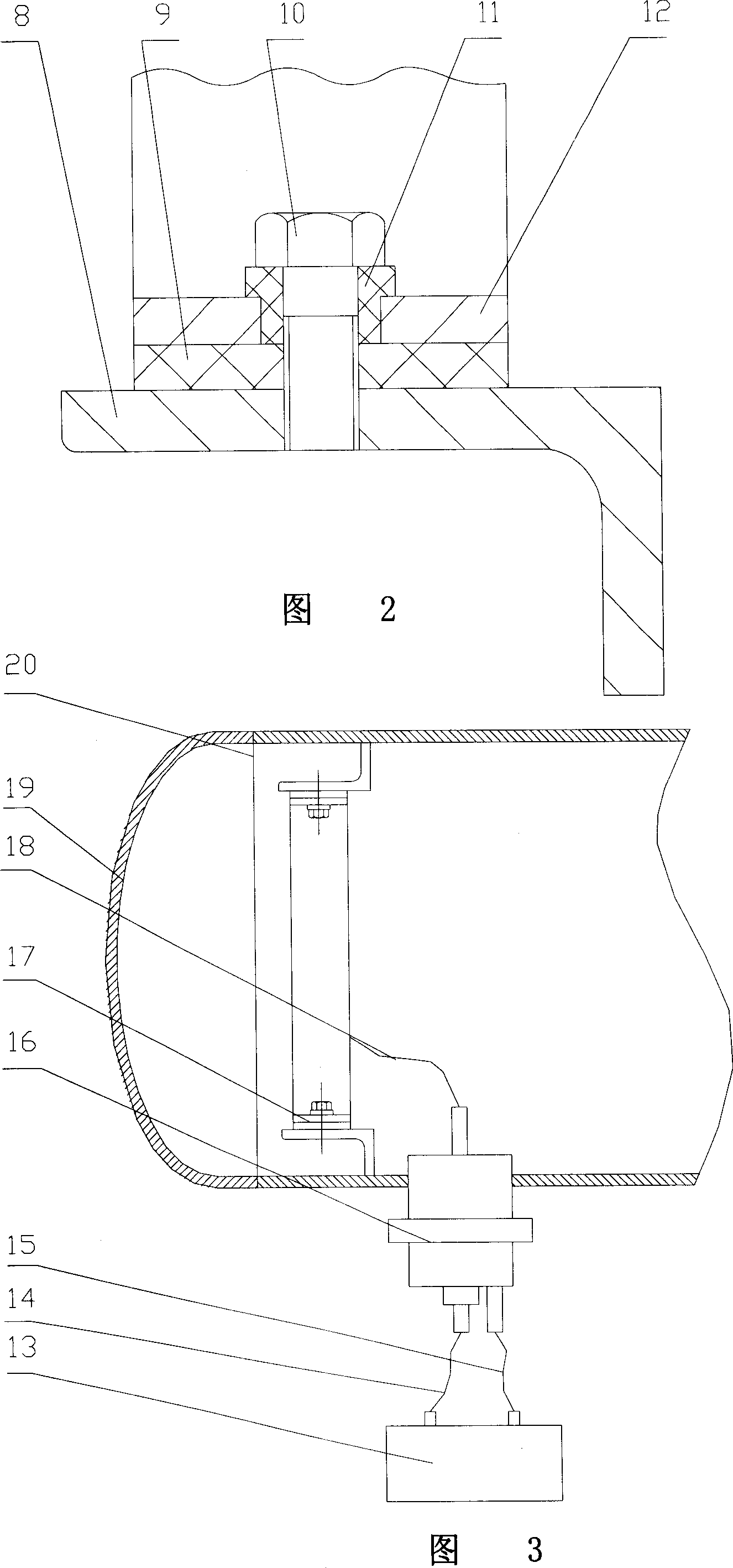

[0016] As shown in FIG. 2 , the auxiliary anode 17 is composed of a bracket 8 , an insulating pad 9 , a fixing bolt 10 , an insulating pad 11 , and an anode connecting coil 12 . The anode connecting coil 12 is a ring st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com