Manipulator of robot and workpiece conveying robot using said manipulator

A technology of robots and manipulators, applied in the field of manipulators, can solve the problems of excessive cooling, easy distortion of manipulators, and inability to cool manipulators, and achieve the effects of efficient cooling, uniform cooling, and efficient and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Next, preferred modes for carrying out the present invention will be described with reference to the drawings.

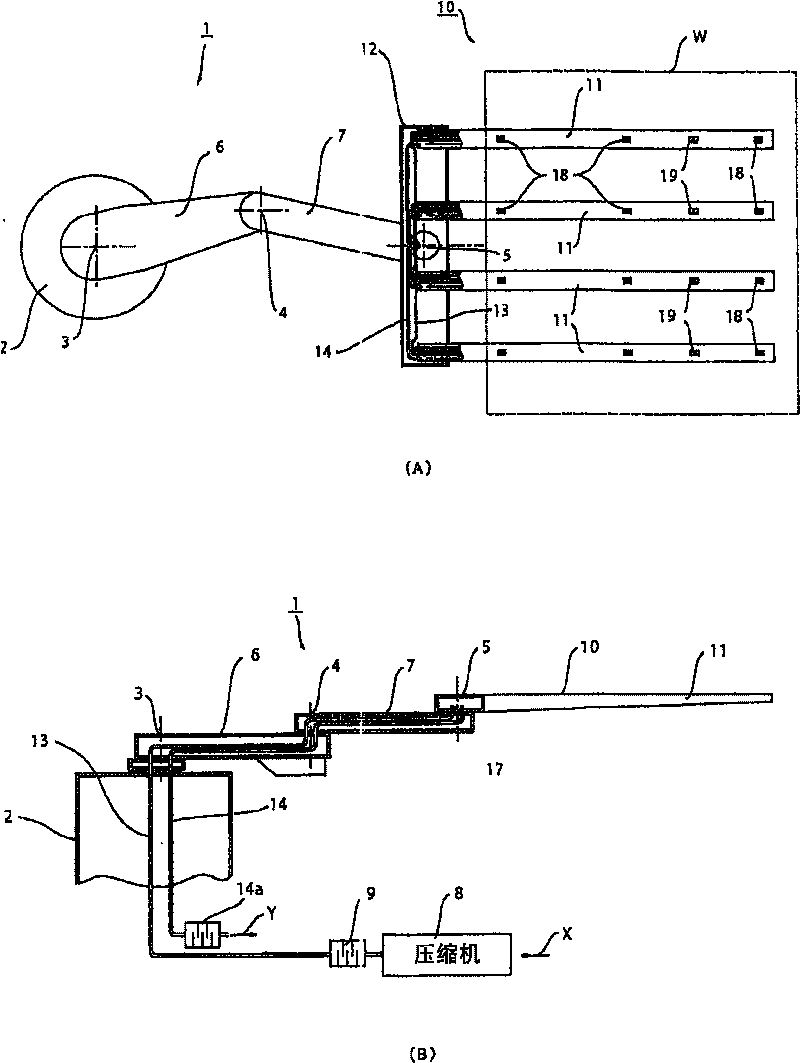

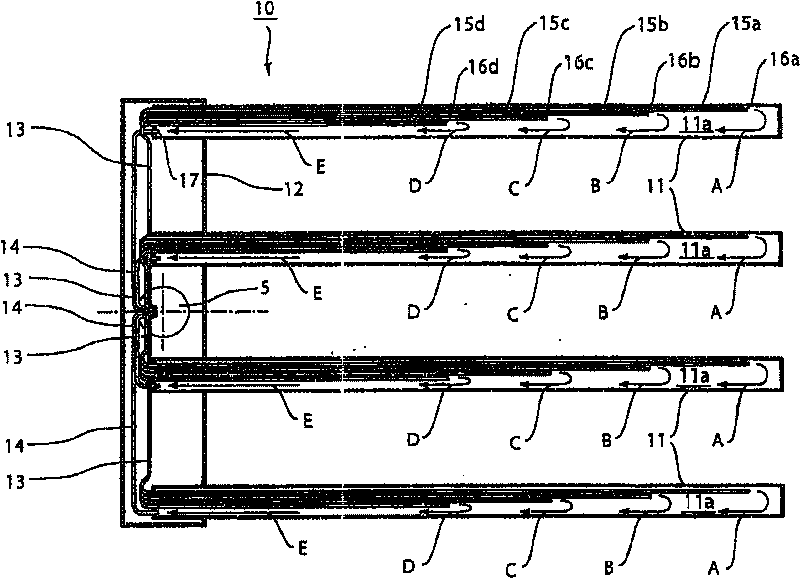

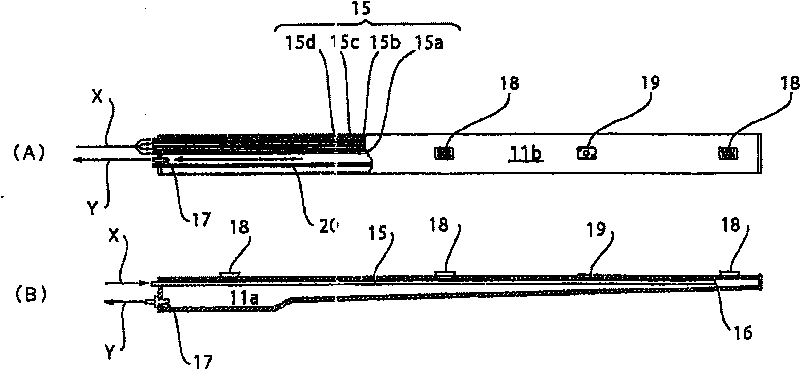

[0044] figure 1 Showing the schematic structure of the workpiece transfer robot of the embodiment of the present invention, figure 1 (A) is a plan view, figure 1 (B) is a side sectional view. The workpiece transfer robot 1 includes a transfer system for carrying a workpiece into and out of a heating furnace in a high-temperature environment, and a robot cooling system for cooling a robot arm. In addition, the workpiece transfer robot 1 of this embodiment is used in a manufacturing process of a flat panel display (FPD) requiring a certain degree of cleanliness, and is used to transfer a glass substrate W as a workpiece.

[0045] (Schematic structure of the conveying system)

[0046] First, the transfer system will be described. The workpiece transfer robot 1 (hereinafter simply referred to as "robot 1") includes: a first arm 6 that can rotate around the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com