Short arc discharge lamp

A discharge lamp and short-arc technology, applied in the field of short-arc discharge lamps, can solve the problems of decreased lamp illumination, increased processing cost and processing time, peeling and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

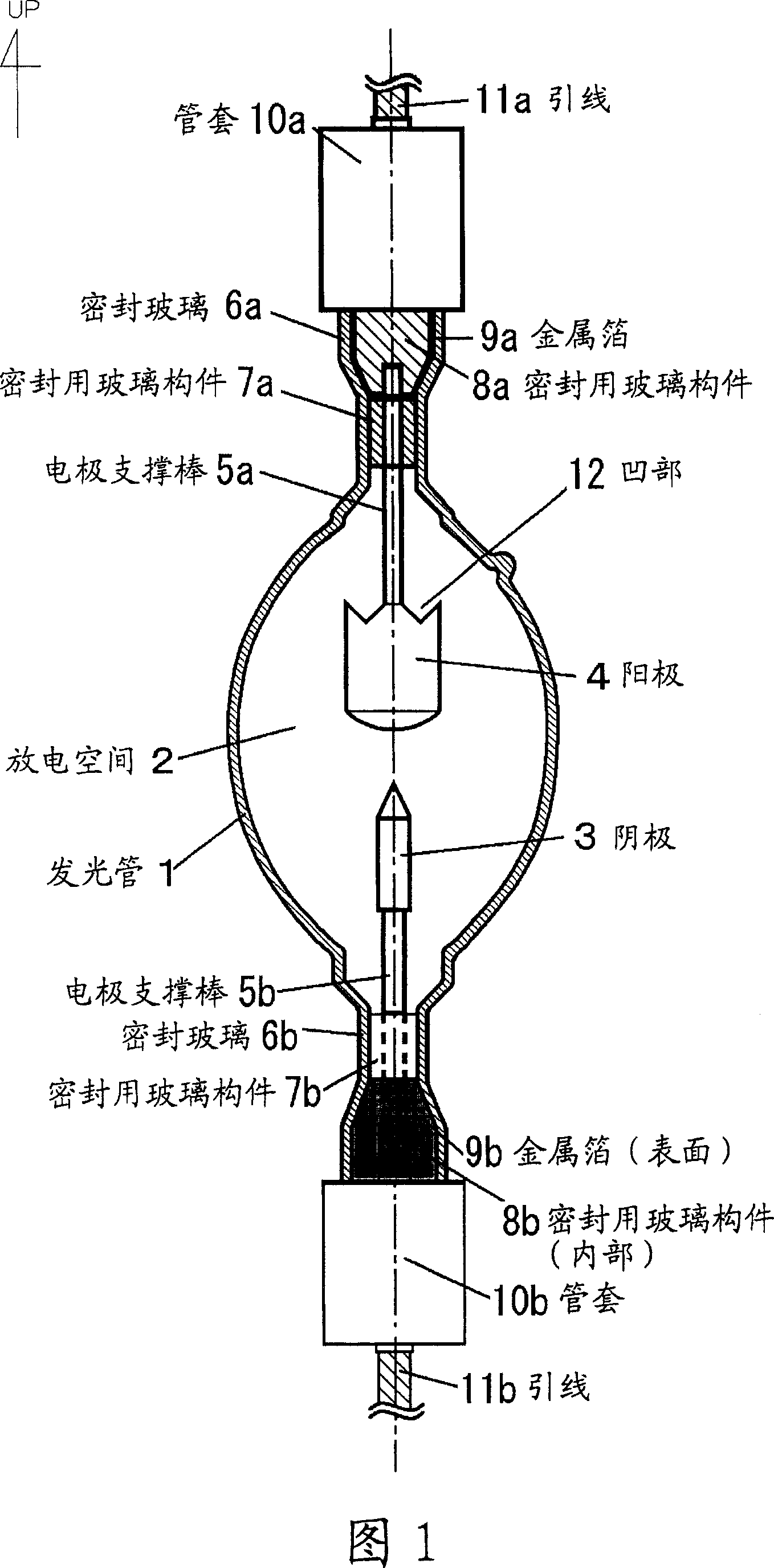

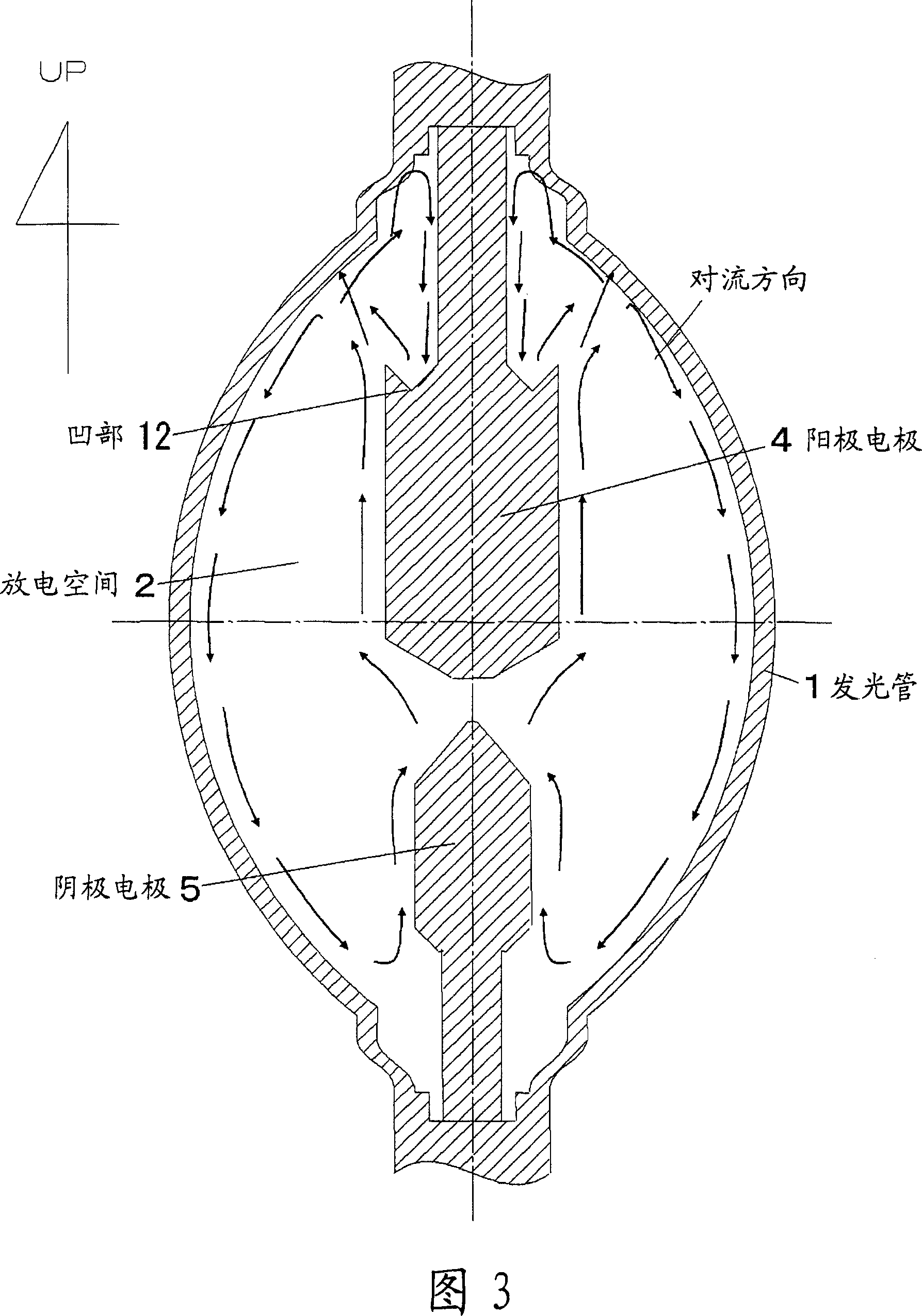

[0031] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to FIGS. 1 to 5 .

[0032] 【Example】

[0033] An embodiment of the present invention is a short-arc discharge lamp in which a concavity with a concave, U-shaped, レ-shaped, or V-shaped cross-sectional shape is provided on the end surface of the light-emitting tube that becomes the upper electrode at the time of lighting. .

[0034] Fig. 1 is a conceptual diagram of a short-arc discharge lamp in an embodiment of the present invention. Fig. 2 is a graph showing the results of a convection simulation of the main air flow of a short-arc type lamp. Fig. 3 is a schematic diagram showing the calculated convective direction of a short-arc type discharge lamp. 4 and 5 are diagrams showing examples of the shape of the rear end surface of the anode of the short-arc lamp.

[0035]In FIGS. 1 to 5 , the arc tube 1 is a bulb of a short-arc discharge lamp. The discharge spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com