Controller and control for electronic ballast resistor and high-performance gas discharging light

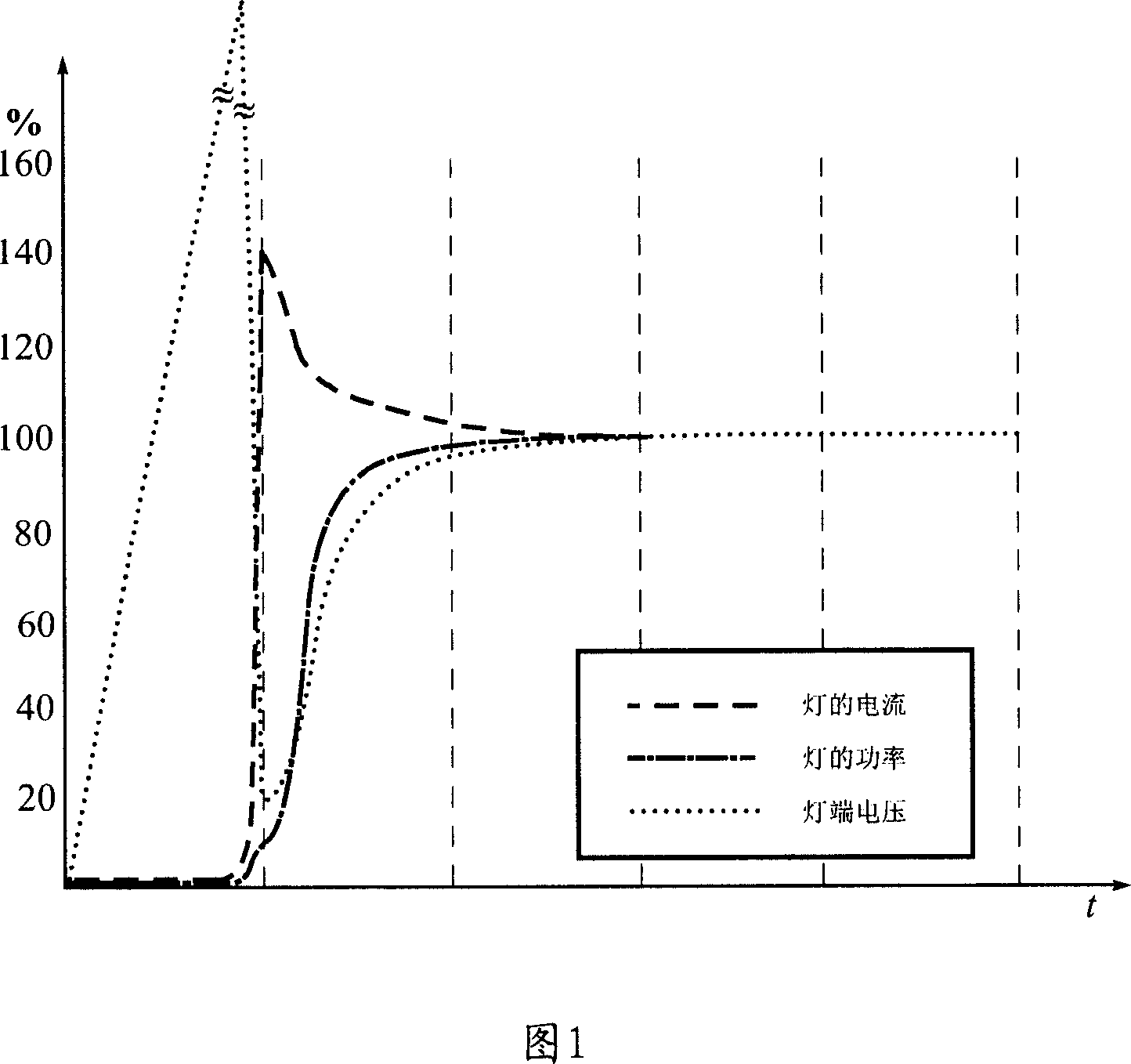

A technology for electronic ballasts and gas discharge lamps, which is applied in the use of gas discharge lamps, lighting devices, electrical components, etc., can solve the problems of large electromagnetic interference, many links, and increased tube pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

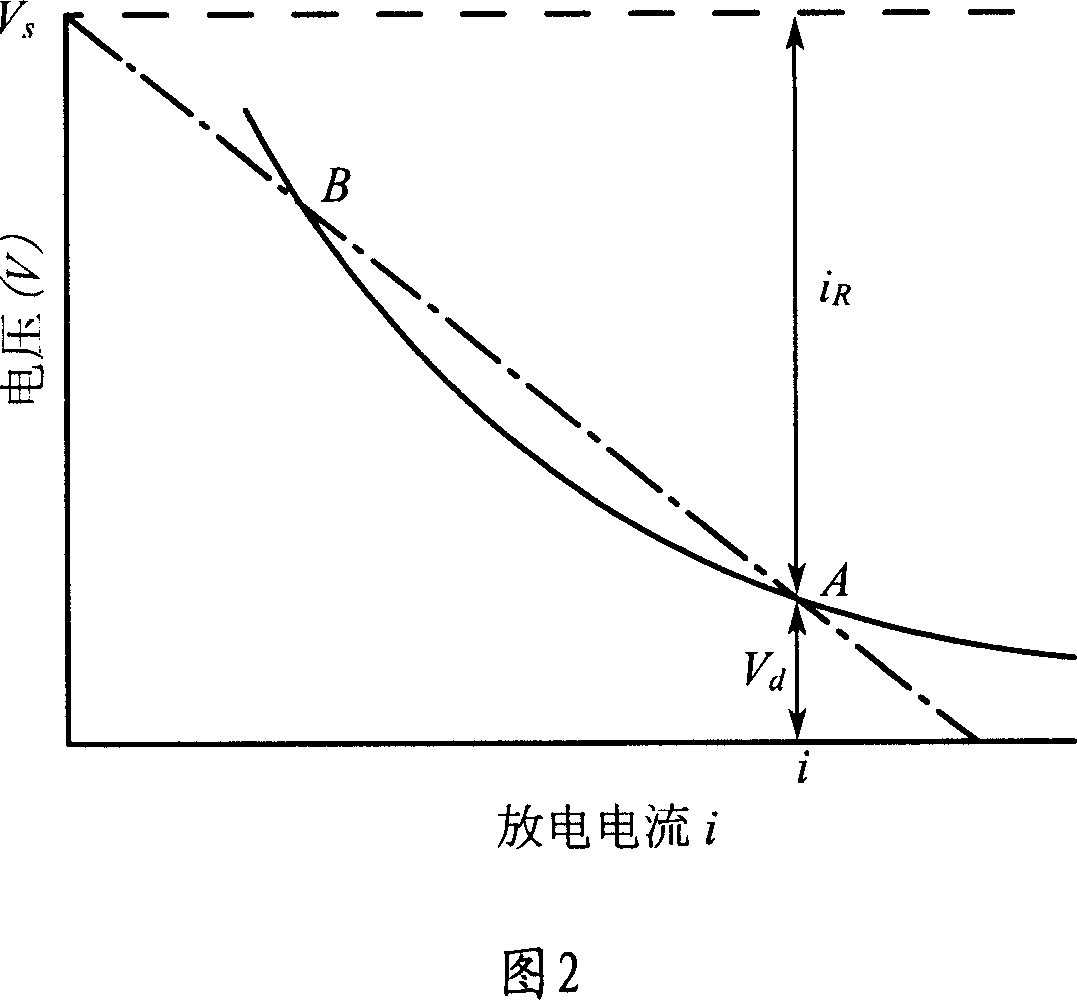

Problems solved by technology

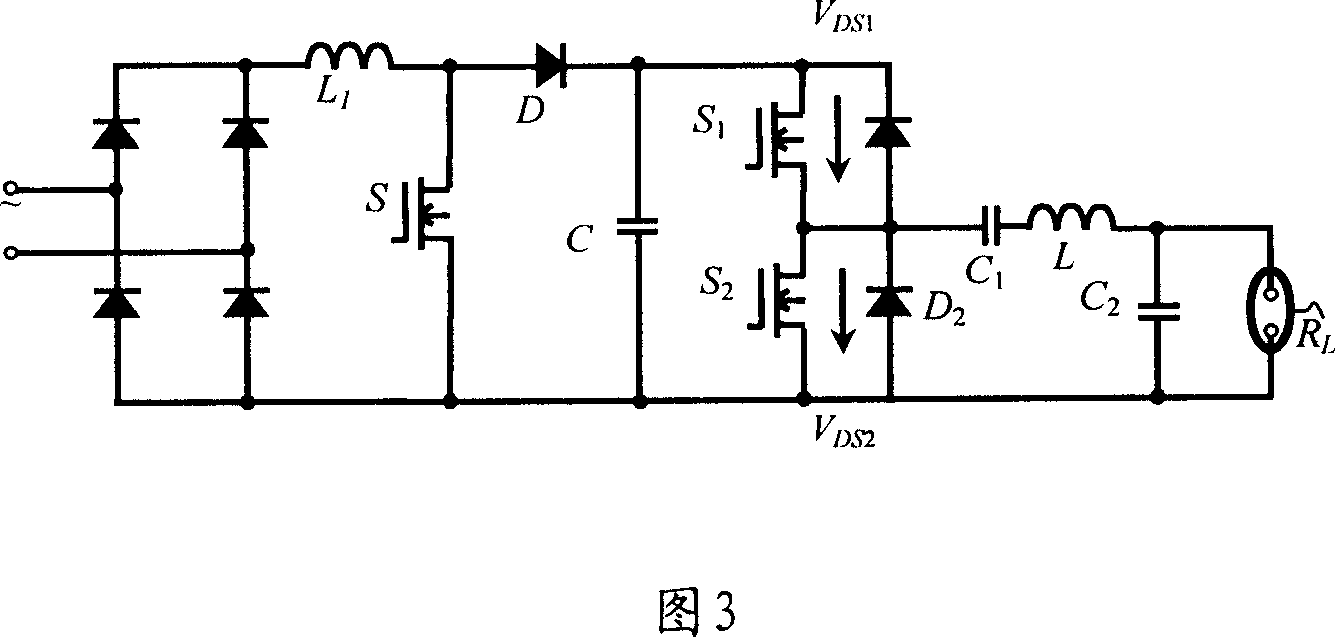

Method used

Image

Examples

Embodiment 3

[0148] A control method based on the high-intensity discharge lamp control device based on the above-mentioned electronic ballast, comprising:

[0149] The first step, the control circuit drives the electronic ballast through the drive circuit according to the working status of the electronic ballast and the high-intensity gas discharge lamp collected by the signal acquisition circuit; it is specifically divided into the following steps:

[0150] 1. The signal acquisition circuit collects the information of the working status of the electronic ballast and the high-intensity gas discharge lamp, and outputs the control signal to the selection status controller and the status controller group; specifically, it can be divided into the following steps:

[0151] (1), the voltage processing circuit of the signal acquisition circuit collects the high-frequency AC voltage signal U of the high-intensity gas discharge lamp R After processing, it becomes one and U R Approximate DC voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com