Process for preparing high purity flake alpha-Al2O3 and its super fine powder

An ultra-fine powder and flake technology, which is applied in the field of preparation of high-purity flake α-Al2O3 and its ultra-fine powder, can solve the problems of complex process and difficulty in preparing high-purity flake α, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) The analytically pure aluminum nitrate nonahydrate is mixed with soluble starch and other qualities, and ground uniformly at room temperature;

[0017] (2) Put the evenly ground material directly into a drying oven at 150°C and heat for 30 minutes to obtain a yellow fluffy product;

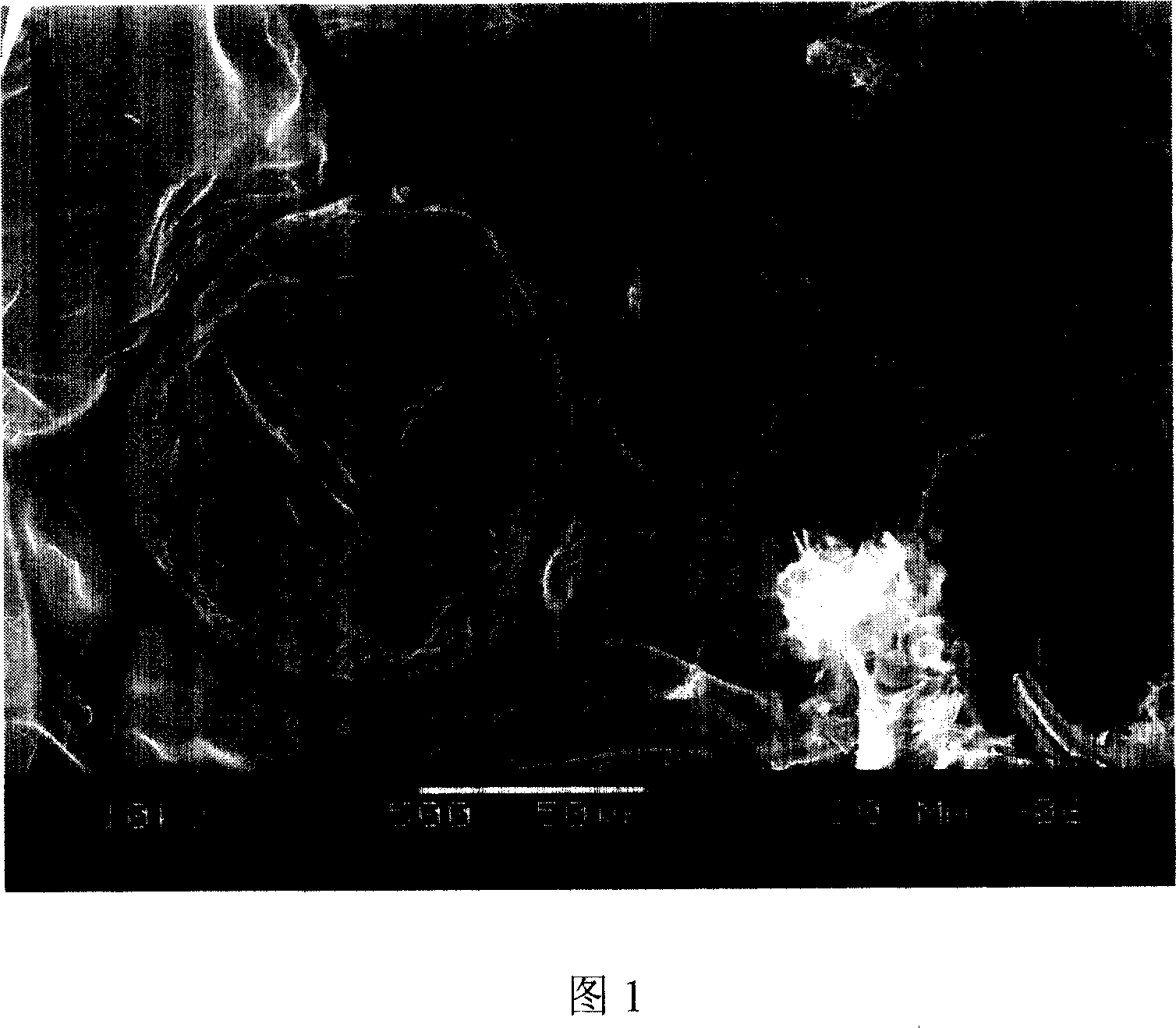

[0018] (3) Incubate the yellow fluffy product at 1000°C for 2 hours to obtain high-purity flake α-Al 2 O 3 ;

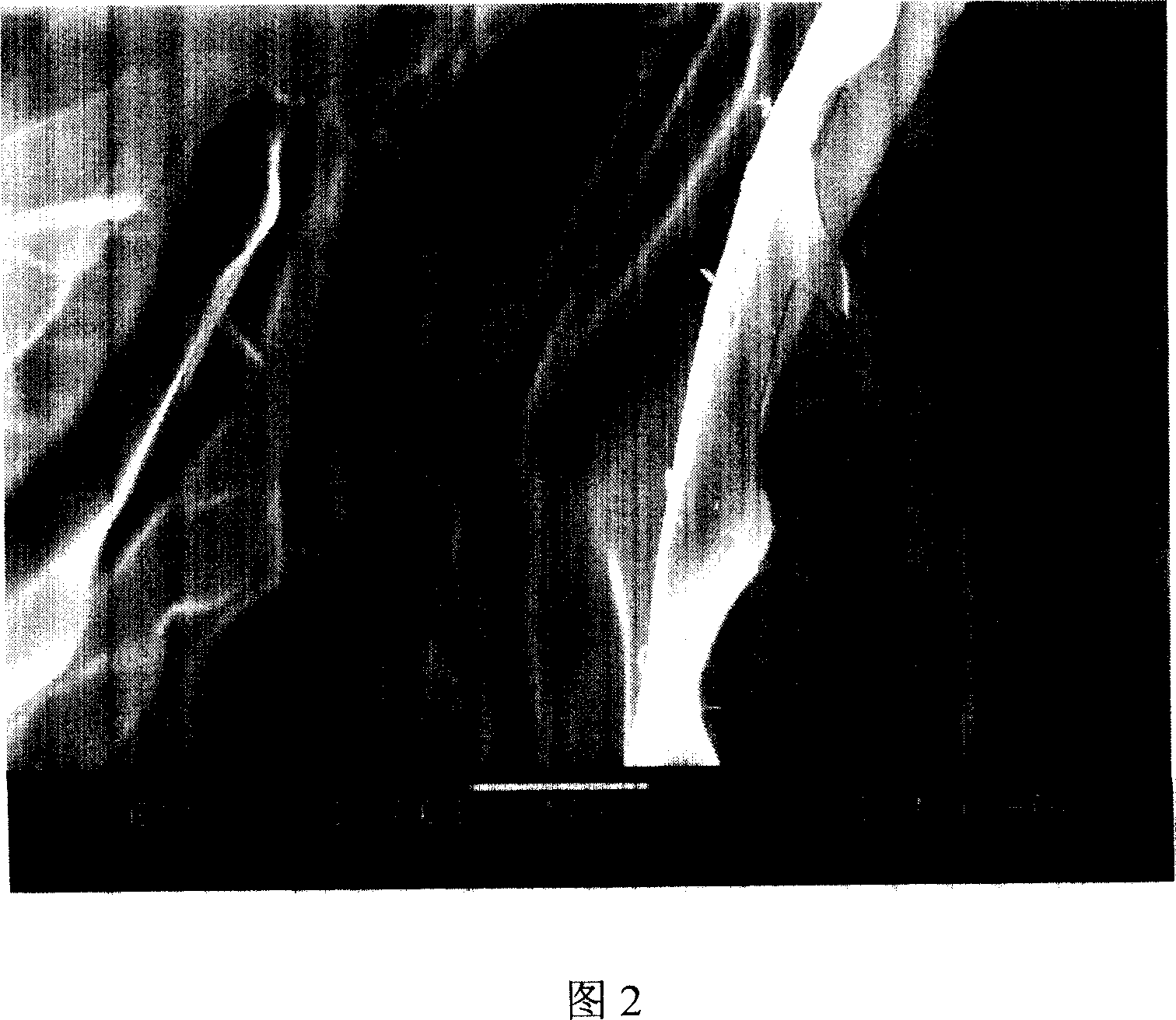

[0019] (4) 100 parts by mass of the high-purity flaky α-Al obtained above 2 O 3 , adding 500 parts by mass of anhydrous ethanol, and ball milling with a common ball mill for 24 hours; the slurry was directly dried at 80 ° C to obtain high-purity ultra-fine flake α-Al with an average particle size of 0.35 μm 2 O 3 .

Embodiment 2

[0021] (1) analytically pure aluminum nitrate nonahydrate and tapioca starch are mixed, and ground uniformly at room temperature;

[0022] (2) Put the evenly ground material directly into a drying oven at 150°C and heat for 30 minutes to obtain a yellow fluffy product;

[0023] (3) Incubate the yellow fluffy product at 1200°C for 1 hour to obtain high-purity flake α-Al 2 O 3 .

[0024] (4) 100 parts by mass of the high-purity flaky α-Al obtained above 2 O 3 , adding 600 parts by mass of anhydrous ethanol, and ball milling with a common ball mill for 24 hours; the slurry was directly dried at 80 ° C to obtain high-purity ultra-fine flake α-Al with an average particle size of 0.5 μm 2 O 3 .

Embodiment 3

[0026] (1) The analytically pure aluminum nitrate nonahydrate is mixed with the same quality as gum arabic, and ground uniformly at room temperature;

[0027] (2) Put the evenly ground material directly into a drying oven at 150°C and heat for 30 minutes to obtain a yellow fluffy product;

[0028] (3) Incubate the yellow fluffy product at 1000°C for 2 hours to obtain high-purity flake α-Al 2 O 3 .

[0029] (4) 100 parts by mass of the high-purity flaky α-Al obtained above 2 O 3 , adding 500 parts by mass of anhydrous ethanol, and milling with a common ball mill for 24 hours; the slurry was directly dried at 80 °C to obtain high-purity ultra-fine flake α-Al with an average particle size of 0.4 μm 2 O 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com