Near-infrared-absorbing glass, near-infrared-absorbing element having the same and image-sensing device

An absorbing element, near-infrared technology, applied in glass molding, glass pressing, optical components, etc., can solve the problems of large environmental load, difficulty in producing glass with high fluorine content, large volume, etc., to achieve excellent weather resistance, Excellent near-infrared absorption characteristics, high transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

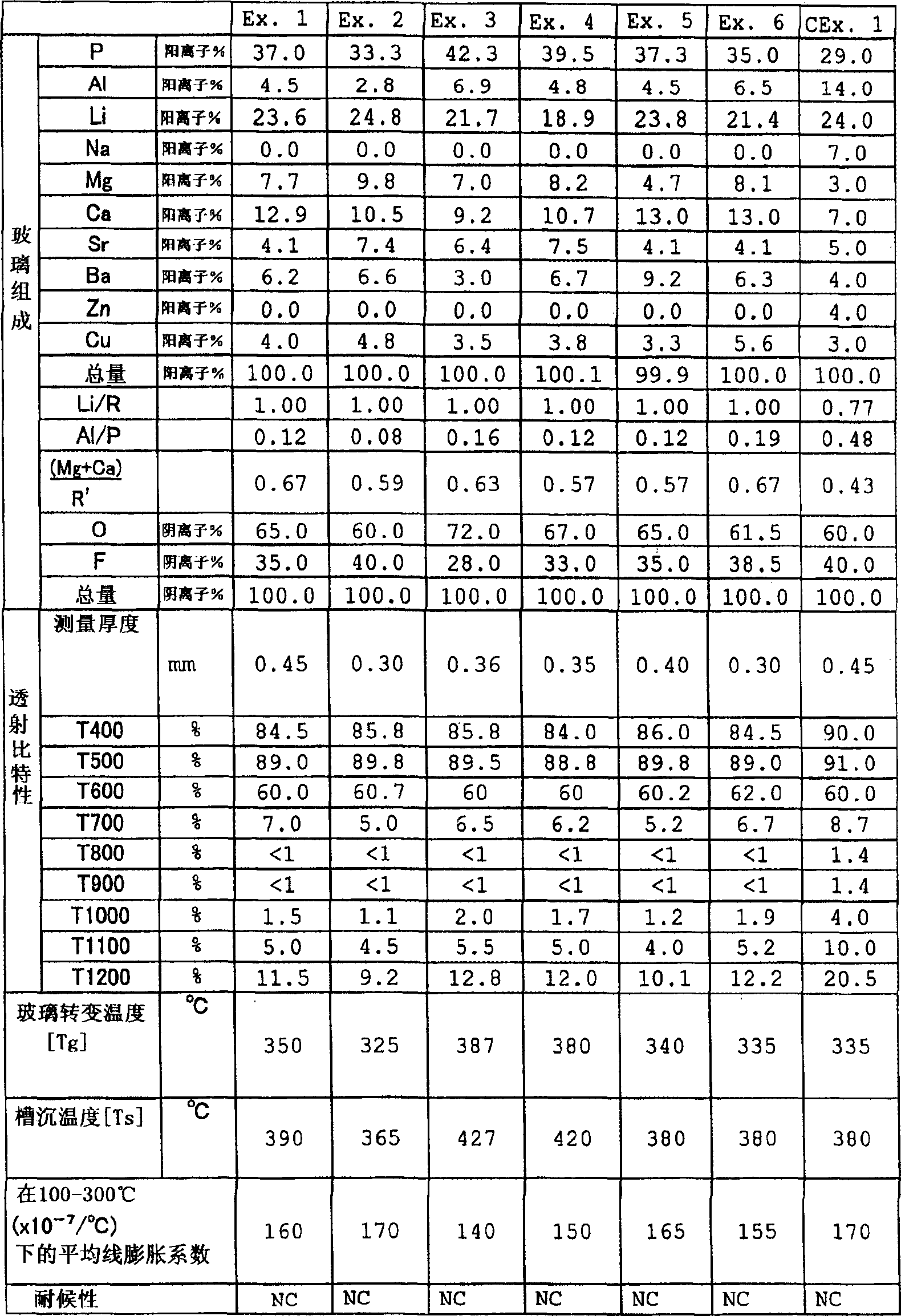

[0093] Oxide materials including phosphate and fluoride materials were weighed to obtain compositions shown in Table 1, and they were mixed and melted in a crucible made of platinum. The glasses in Examples 1-6 were melted at 800 to 900°C, while the glass in Comparative Example 1 was melted at 1300°C.

[0094] Each glass is stirred and clarified before being poured onto iron plates to form blocks. The glass block is fed into a furnace, preheated to a temperature around the glass transition temperature, and annealed to room temperature to obtain a near-infrared absorbing glass.

[0095] Samples for measurement were taken from the blocks obtained above by cutting and various properties were measured as follows. Table 1 shows the results.

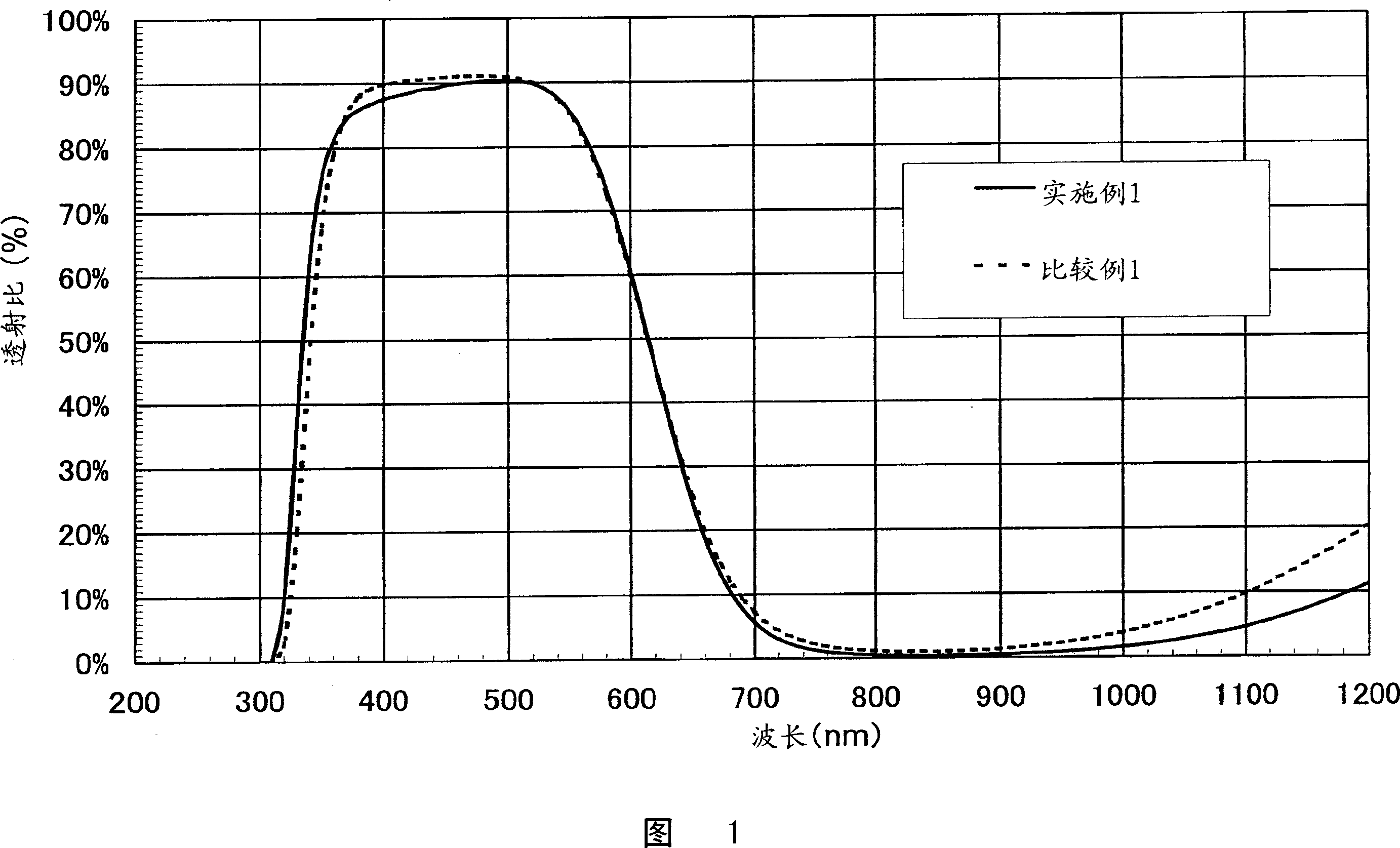

[0096] (1) Transmittance characteristics

[0097] The spectral transmittance at a wavelength of 200 to 1200 nm of the polished glass having the thickness shown in Table 1 was measured with a spectrophotometer. Table 1 shows the transmittan...

Embodiment 7

[0117] By performing glass dissolution, clarification, homogenization, and mold casting in the same manner as in Examples 1 to 6, sheet glass composed of glass having the same composition as in Examples 1 to 6 was obtained. Each sheet glass is sliced and each of both surfaces of the sliced glass is optically polished to obtain a glass plate having a predetermined thickness. These glass plates were subjected to a cutting process to obtain near-infrared absorbing glass plates having a predetermined thickness and size. The thickness of each glass plate was adjusted so that the transmittance at a wavelength of 615±10 nm was 50% (the thickness corresponds to the measured thickness in Table 1), and each glass plate had a size of 10 mm×10 mm to 30 mm×30 mm. Then, quartz processed into a plate shape and two thin plate glasses formed of optical glass (BK-7) were prepared separately, and both sides of each plate were optically polished. A glass plate formed of near-infrared absorbi...

Embodiment 8

[0119] A glass frit was prepared by melting, clarifying, and homogenizing the glass in the same manner as in Examples 1 to 6, and the glass frit was flowed down from a nozzle composed of platinum. An appropriate amount of glass frit is received into a receiving mold and shaped into an aspheric glass preform. Once the shaped preform has cooled to room temperature, the preform is resoftened by reheating in a non-oxidizing atmosphere comprising nitrogen or a mixture of nitrogen and hydrogen and compressed with a compression die. The molding surfaces of the stamper are precisely machined into the inverse shape of the desired optical element in advance, and the shapes of these molding surfaces are precisely transferred to the glass in the above-mentioned pressing step. The molded product is cooled in the press mold to a temperature at which the glass does not deform, and then it is taken out of the press mold and annealed. In the manner described above, optical elements such as sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com