Compound glossy ganoderma spore oil and its preparing method

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in the direction of fat oil/fat production and fat production, and can solve the problems of undisclosed composition of Ganoderma lucidum oil, loss of active ingredients, and difficulties in preparation work, and achieve clear chemical composition and strong action Large, solve the effect of security and incomplete extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 3 kg of Ganoderma lucidum spore powder with a wall-breaking rate of more than 95%, crush it into 2 kg of 200-mesh Ganoderma lucidum mycelium powder, add 50 g of starch, mix evenly, and directly dry-press the granules with a dry-press granulator, the main pressure is 5 MPa, and the side pressure is 5 MPa. 0.5MPa, made into 0.2 ~ 0.3cm granules, sieved, sieved to remove the fine powder above 60 mesh, and then the fine powder was granulated by the same method. The prepared spore powder particles were placed in a supercritical carbon dioxide extraction kettle, CO 2 Pressurized by a high-pressure pump and circulated for extraction. The pressure of the extraction tank is 25MPa, the temperature is 40°C, the primary separation is 10MPa, 42°C, and the secondary separation is 5MPa, 32°C. After continuous extraction for 3 hours, the spore oil was collected in a separator to obtain 764.8 g of compound Ganoderma lucidum spore oil with a special smell of light yellow spore powd...

Embodiment 2

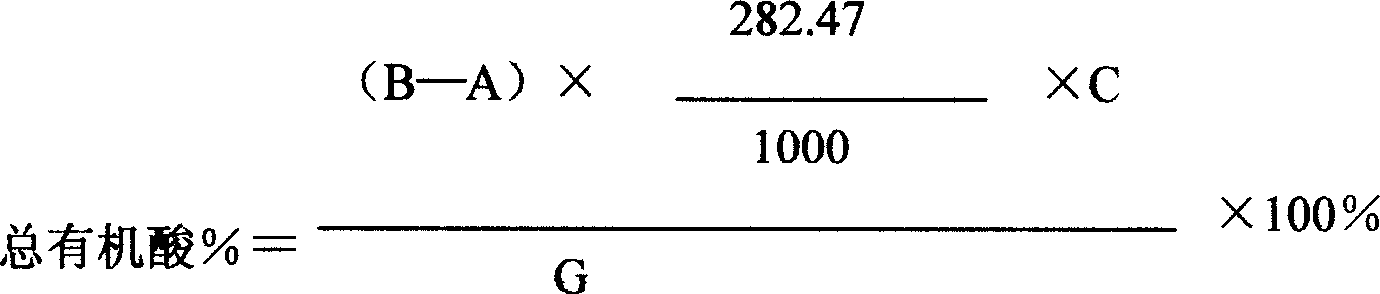

[0031] Get 5kg of Ganoderma lucidum spore powder of red lucidum with a wall-breaking rate of more than 95%, add 50g of starch, extract with the same experimental conditions and methods as in Example 1, and obtain 905.1g of pure Ganoderma lucidum spore oil with a special smell of light yellow spore powder. Rate 18.21%. Wherein: the content of total organic acid is 93.73%, the content of total ganoderma acid is 0.42%, and the acid value is 13.9. Comparing the obtained pure ganoderma spore oil with the compound ganoderma spore oil of Example 1, the content of total ganoderma acid in the compound ganoderma spore oil is significantly higher.

Embodiment 3

[0033] Take 6kg of broken Ganoderma lucidum spore powder, crush it into 3kg of Ganoderma lucidum mycelium powder of 180 mesh, add 45g of dextrin, mix evenly, and directly dry-press the granules with a dry-press granulator, the main pressure is 8MPa, and the side pressure is 0.8MPa to make 0.1 ~0.2cm particles, sieve, sieve to remove fine powder above 60 mesh, fine powder is granulated again by the same method. The prepared composite spore powder particles are placed in a supercritical carbon dioxide extraction kettle, CO 2 Pressurized by a high-pressure pump and circulated for extraction. The pressure of the extraction kettle is 34MPa, the temperature is 30°C, the primary separation is 9MPa, 38°C, and the secondary separation is 4MPa, 28°C. After continuous extraction for 2.5 hours, the spore oil was collected in a separator to obtain 1482.3 g of compound Ganoderma lucidum spore oil with a light yellow color and a special smell of spore powder, with a yield of 16.47%. Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com