Method for operating an internal combustion engine, and internal combustion engine for carrying out said method

An internal combustion engine and exhaust valve technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve problems such as reducing the effective efficiency of the engine, and achieve the effects of improving fuel consumption, reducing ignition lag time, and reducing residual gas content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

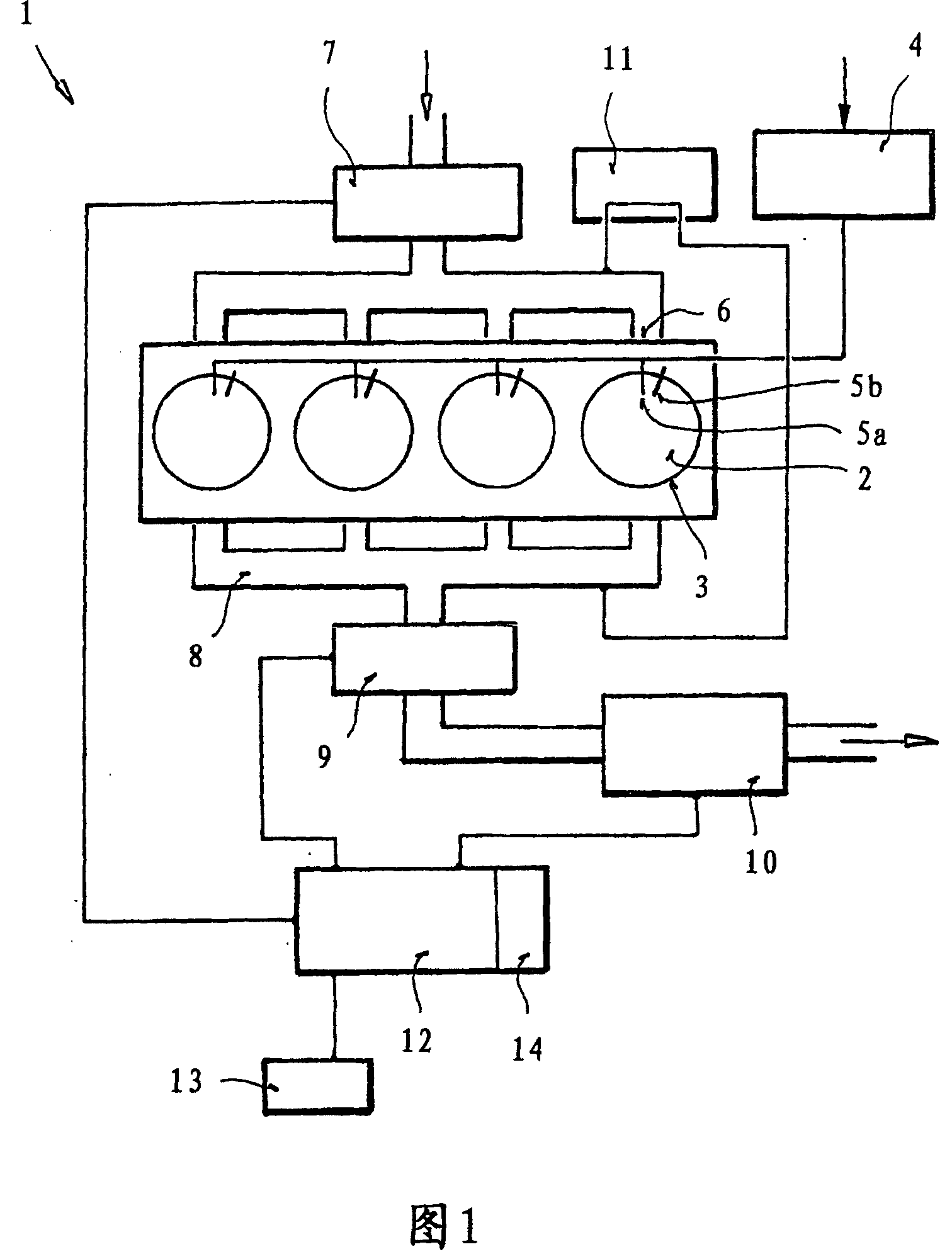

[0035] exist figure 1 A schematic diagram of a turbocharged four-cylinder internal combustion engine 1 according to the invention is shown in . Fuel can enter the combustion chamber 2 of the cylinder 3 via a fuel supply 4 , which is indicated by an arrow on the fuel supply 4 . Each cylinder has an intake valve 5a and an exhaust valve 5b.

[0036] The mixture supply takes place via a mixture supply device 6 . An air compressor 7 is located in the intake region of internal combustion engine 1 . The air supply is indicated by an arrow on the air compressor 7 . The exhaust system 8 has an exhaust gas turbine 9 that can be driven by exhaust gas. It goes without saying that the invention can also be realized in principle in internal combustion engines without exhaust gas supercharging. Furthermore, a catalytic converter 10 is arranged in the exhaust system 8 . The composition of the combustion mixture can be influenced by means of an exhaust gas recirculation device 11 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com