Microwave technology used in preparing polymeric ferric sulfate from pyrite burned slag pickling liquid

A technology for polymerizing ferric sulfate and pyrite slag, which is applied in the fields of ferric sulfate, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of long reaction time, large equipment volume, unstable product quality, etc., and achieve the solution of reaction time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

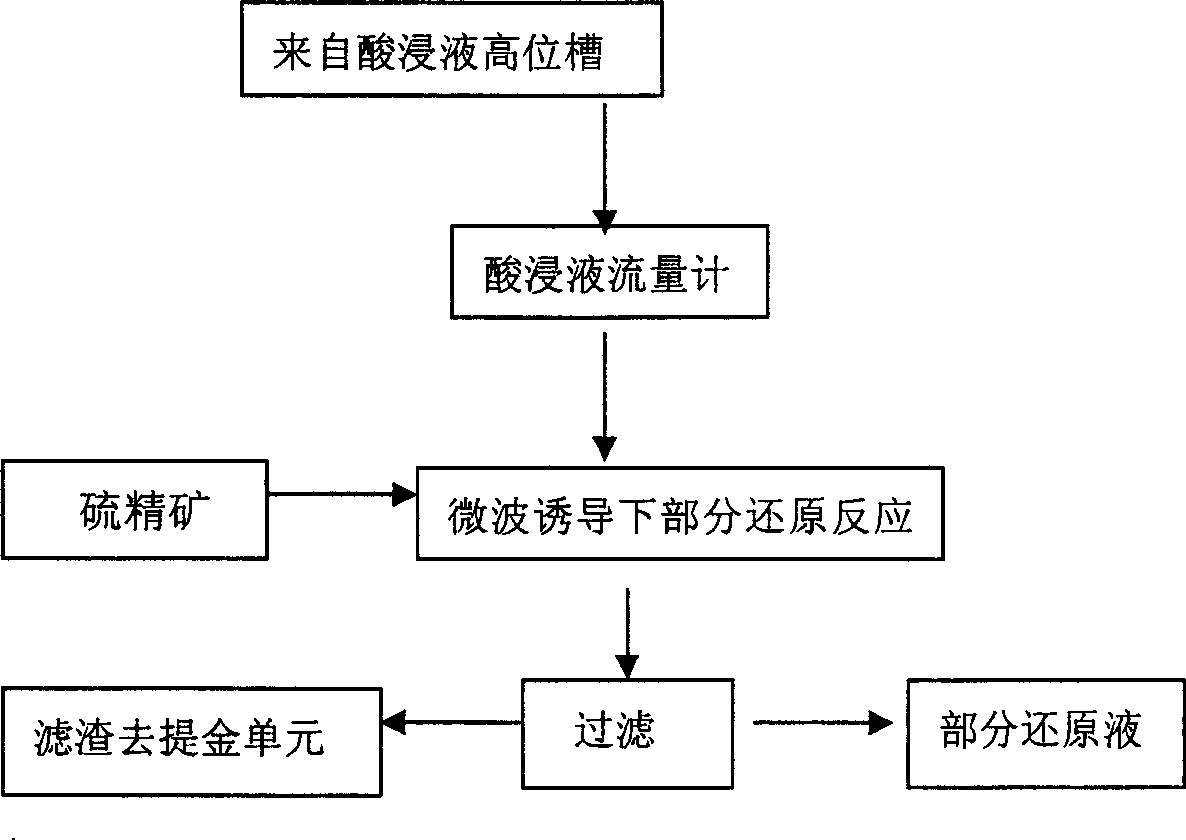

Method used

Image

Examples

Embodiment 1

[0021] Example 1, put 25g of activated sulfur concentrate into a 500mL single-necked flask, then add 200mL of [TF]=134g / L pickling solution, then put it into a microwave reactor for microwave induction reaction. Control the temperature at 70°C, the reaction time is 30min, filter the reducing solution, the reduction rate can reach 40%, adjust the pH value of the filtrate to 1-2, add 3.2g of sodium chlorate, and microwave at 30°C for 30min, the product base Degree 11%

Embodiment 2

[0022] Example 2, put 25g of activated sulfur concentrate into a 500mL single-necked flask, then add [TF]=147g / L pickling solution 200mL, put it into a microwave reactor for microwave induction for 30min, and the reaction temperature is 90°C , filter the reducing solution, the reduction rate can reach 42%, adjust the pH value of the filtrate to 1~2, add 3.7g sodium chlorate, and microwave at 30°C for 30 minutes, the basicity of the product is 13%

Embodiment 3

[0023] Example 3, take 25g of activated sulfur concentrate and put it into a 500mL single-necked flask, then add [TF]=142g / L pickling solution 200mL, put it into a microwave reactor for microwave induction for 30min, and the reaction temperature is 90°C , filter the reduction solution, the reduction rate can reach 42%, adjust the pH value of the filtrate to 1-2, add 3.6g of sodium chlorate, irradiate with microwave at 30°C for 30 minutes, and the basicity of the product is 12.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com