White high performance epoxy resin antirust bottom paint

A technology of epoxy resin and anti-rust primer, which is applied in the field of paint making, and can solve the problems of increasing coating costs and ineffective use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

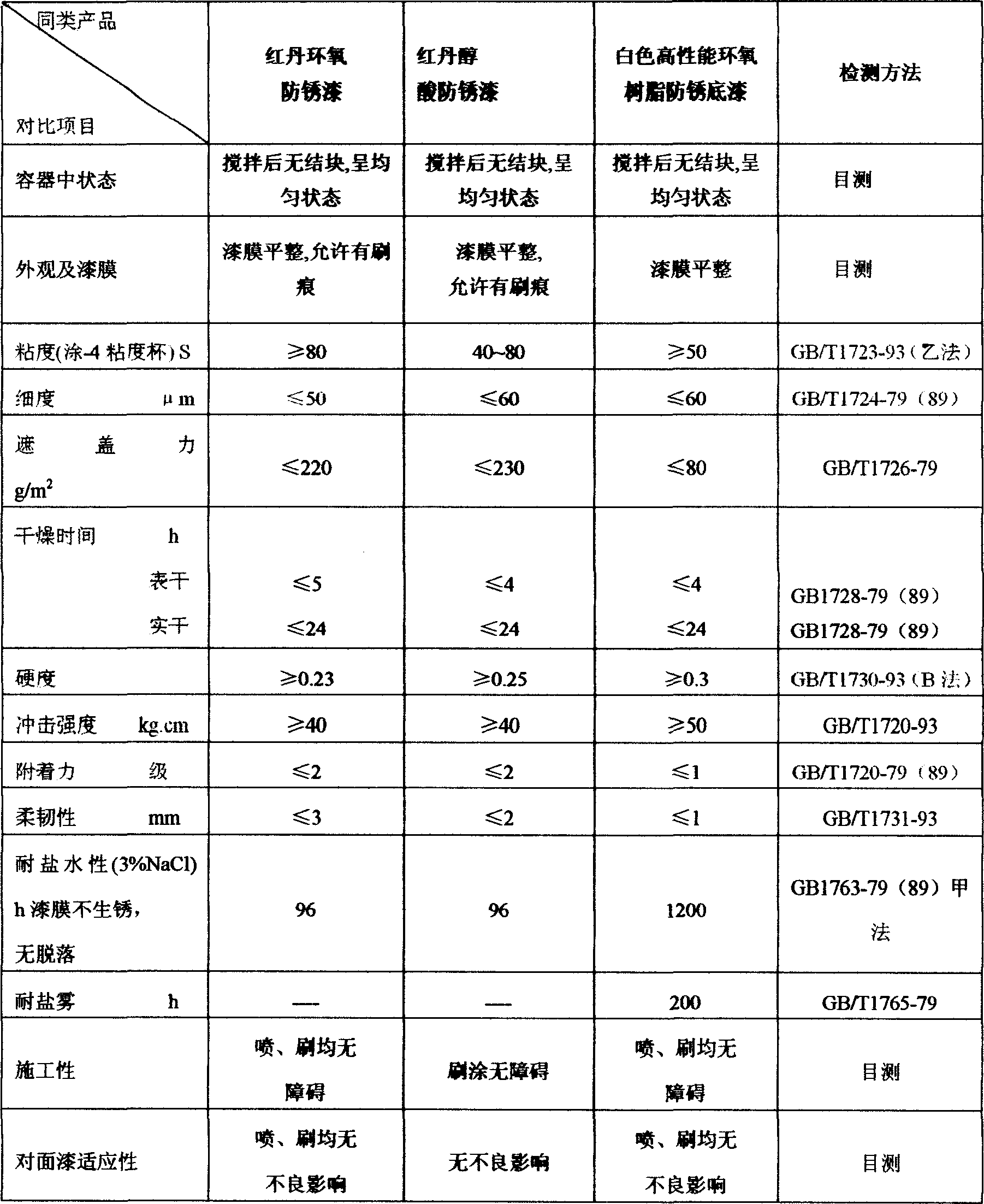

Image

Examples

Embodiment 1

[0034] The component weight of white high-performance epoxy resin antirust primer of the present invention is Kg:

[0035] epoxy resin 27

[0036] White composite silicon titanium antirust powder 60

[0037] Organic bentonite 10

[0038] 923S 1

[0039] Butanol, xylene mixture 2

[0040] The component weight of white composite silicon-titanium antirust powder is Kg:

[0041] 200 mesh silicate 80

[0043] Phthalate coupling agent 5

[0044] Light calcium powder, talcum powder mixture 10

[0045] Put 80Kg of 200-mesh silicate, 10Kg of light calcium powder and talcum powder mixture filler, 5Kg of nano-titanium oxide, and 5Kg of phthalate coupling agent, mix well, and set aside;

[0046] 1. First, add 9Kg of epoxy resin to 1Kg of 923S dispersant and pre-mix for 5-10 minutes, then disperse and evenly add 10Kg of organic bentonite, an anti-sedimentation agent, and mix evenly, then add 2Kg of butanol and xylene mixture and mix evenly .

[0047...

Embodiment 2

[0049] The component weight of white high-performance epoxy resin antirust primer of the present invention is Kg:

[0050] epoxy resin 42

[0051] White composite silicon titanium antirust powder 45

[0052] 201P 7

[0053] YB201A 2

[0054] Butanol 1

[0055] The component weight of white composite silicon-titanium antirust powder is Kg:

[0056] 800 mesh silicate 65

[0057] Nano Titanium Oxide 2.5

[0058] Phthalate coupling agent 2.5

[0059] Light calcium powder, talcum powder mixture 30

[0060] Put 65Kg of 800-mesh silicate, 30Kg filler of light calcium powder and talcum powder mixture, 2.5Kg of nano-titanium oxide, and 2.5Kg of phthalate coupling agent, mix well, and set aside;

[0061] 1. First, add 13Kg of epoxy resin into 2Kg of YB201A dispersant and pre-mix for 5-10 minutes, then add 71Kg of anti-sedimentation agent 201P and mix evenly, then add 1Kg of butanol solvent and mix evenly.

[0062] 2. Disperse and add 45Kg of white composite silicon-titanium ant...

Embodiment 3

[0064] The component weight of white high-performance epoxy resin antirust primer of the present invention is Kg:

[0065] epoxy resin 37

[0066] White composite silicon titanium antirust powder 55

[0067] Organic bentonite, 201P mixture 6

[0068] 923S, YB201A mixture 0.5

[0069] while toluene 1.5

[0070] The component weight of white composite silicon-titanium antirust powder is Kg:

[0071] 1200 mesh silicate 71

[0073] Phthalate coupling agent 1

[0074] Light calcium powder, talcum powder mixture 25

[0075]Put 71Kg of 1200-mesh silicate, 25Kg of light calcium powder, talc mixture as filler, 3Kg of nano-titanium oxide, and 1Kg of phthalate coupling agent together, mix well, and set aside for later use;

[0076] 1. First, add 12Kg of epoxy resin to 0.5Kg of 923S, YB201A mixture dispersant and pre-mix for 5-10 minutes, disperse evenly, add 6Kg of anti-settling agent organobentonite and 201P mixture and mix evenly, then add 1.5 kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com