Magnetite microwave heating agglomerating method and its microwave agglomerating furnace

A technology of microwave heating and sintering method, which is applied in lighting and heating equipment, furnaces, muffle furnaces, etc., can solve application problems and achieve the effects of resource saving, reasonable design, good air permeability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

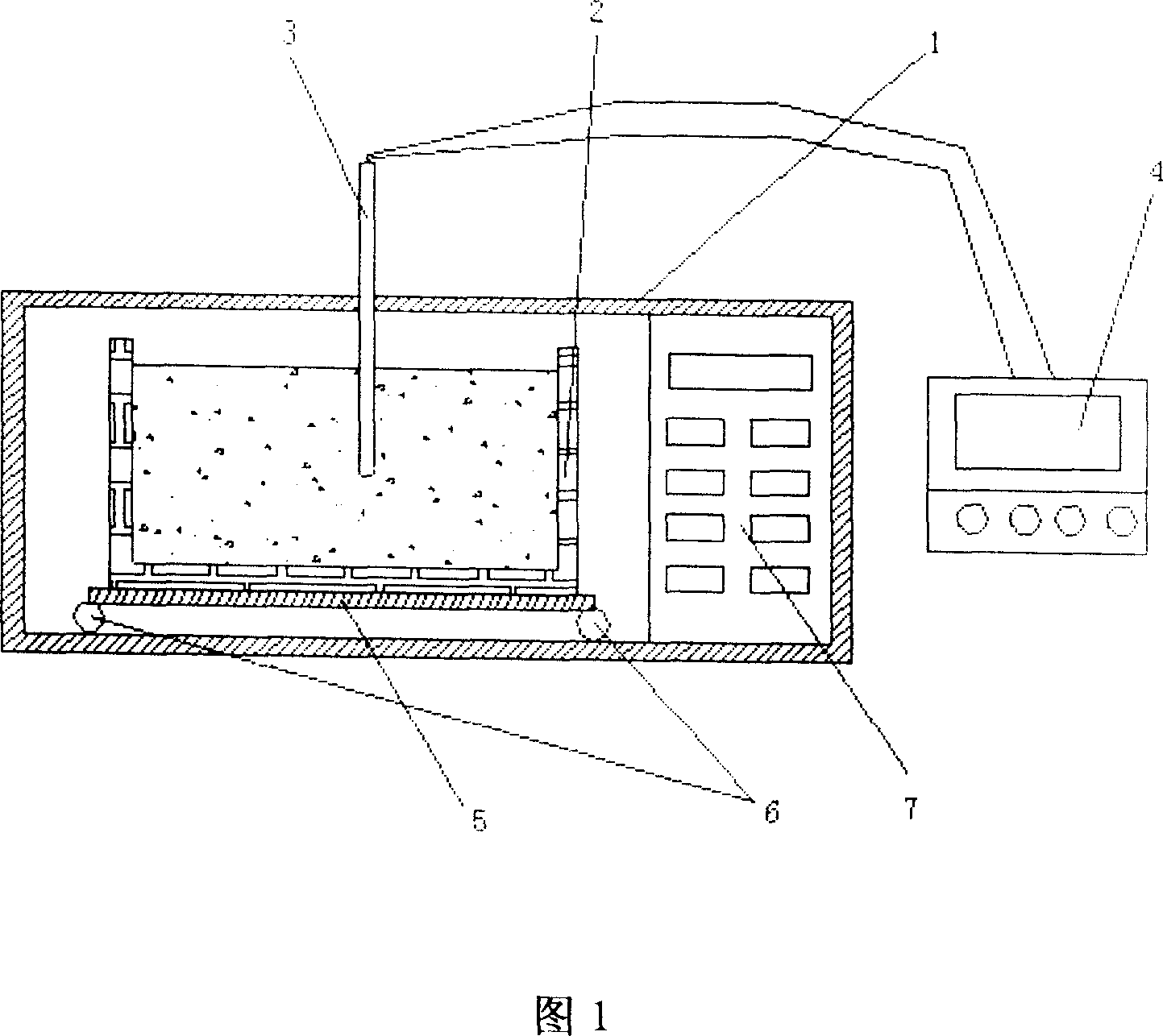

Image

Examples

Embodiment Construction

[0015] A microwave heating and sintering method for magnetite, comprising the steps of:

[0016] 1) According to a batch of concentrate powder used in conventional sintering of iron and steel enterprises, analyze the content of its active ingredients, especially understand SiO 2 , the weight ratio of CaO;

[0017] 2) To make it satisfy SiO 2 : CaO (weight ratio)=1: 2~4, calculate the weight that needs to add CaO in magnetite;

[0018] 3) Add the above-mentioned calculated amount of CaO to the concentrate powder that needs to be sintered, and the particle size of CaO is ≤ 3mm, and mix it evenly;

[0019] 4) Put the homogeneously mixed mixture of magnetite and CaO into a microwave sintering furnace, and microwave sintering at 1100°C to 1300°C for 15 to 30 minutes to obtain a sintered product with good air permeability and hardness.

[0020] Referring to Fig. 1 : a microwave magnetite carbon-free microwave sintering furnace for realizing the above method, including a microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com