Process for preparing lemon chrome

A technology of tartrazine and p-aminobenzenesulfonic acid, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of lack of reaction conversion rate, high product purity, and low content of organic impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

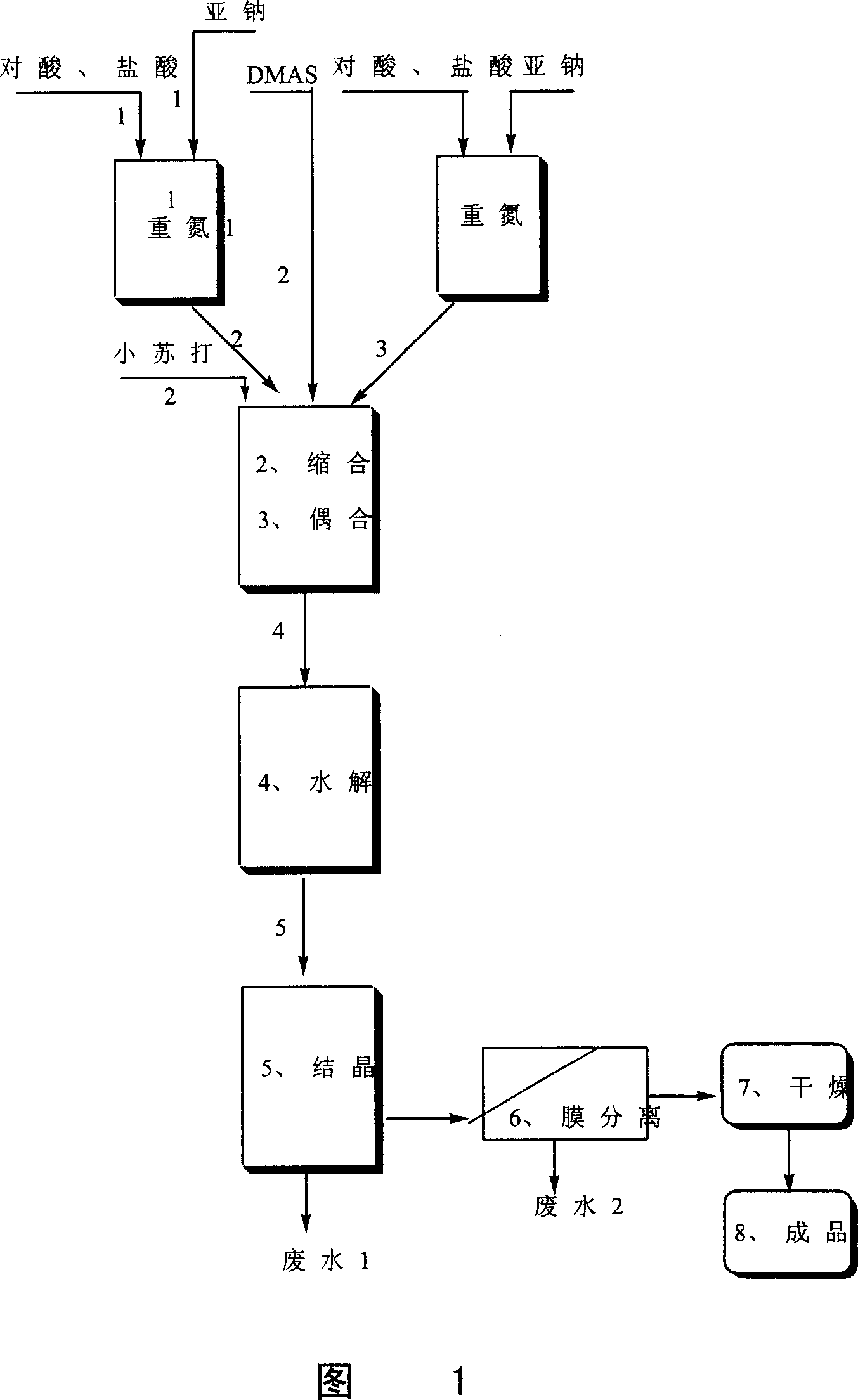

[0040] Figure 1 is a process flow diagram of the preparation method of tartrazine of the present invention. DMAS is dimethyl 2-acetylsuccinate, sodium sulfite is sodium nitrite, and para-acid is p-aminobenzenesulfonic acid.

[0041] As shown in Figure 1, the preparation method of tartrazine according to the present invention includes a diazotization reaction, a condensation reaction, a coupling reaction, a hydrolysis reaction, and post-treatment steps, wherein each post-treatment step includes a crystallization step, a membrane separation step, and a drying step. .

[0042] Phase transfer catalyst

[0043] The phase transfer catalyst is selected from ethanol, Span-Tween series, polyethylene glycol series, Ping Ping O (such as Ping Ping O produced by Shanghai Auxiliary Factory) and other additives or emulsifiers and dispersing agents, preferably polyethylene two The alcohol phase transfer catalyst is more preferably polyethylene glycol 400. The dosage is 0.1-2.0% of the weight of t...

Embodiment 1

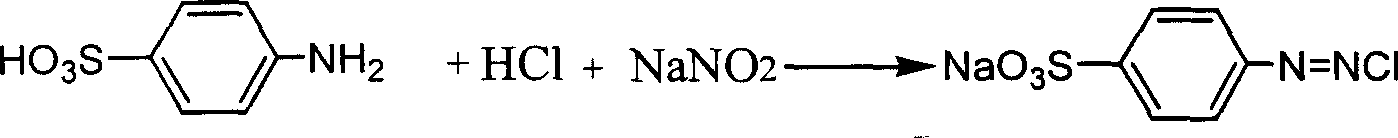

[0063] In a 500mL four-necked flask, add 180mL of hot water at 60°C, add 20g of polyethylene glycol 400 (PEG-400), add 34.6g (0.20mol) of p-aminobenzenesulfonic acid with rapid stirring, stir for ten minutes, and cool to room temperature. Add 32 mL of industrial hydrochloric acid (31%). Continue to cool to 0-5°C, add dropwise 30% sodium nitrite solution 47g (0.20mol) under the liquid, maintain the temperature at 5-10°C, about 20min after adding, the Congo red test paper is blue and the potassium iodide starch test paper is light blue. After the addition, continue to stir for 20 minutes, add a small amount of sulfamic acid to eliminate excess nitrous acid.

[0064] In the above diazonium solution, after stirring for 5 minutes, add 37.64g (0.20mol) of DMAS (dimethyl 2-acetylsuccinate) in a trickle, control the temperature at 10-15℃, and slowly add 15wt% disodium hydrogen phosphate solution dropwise Adjust the pH to 5.0, and the system turns into a transparent wine red. After the dia...

Embodiment 2

[0069] Use 15 g polyethylene glycol 1000 (PEG-1000) instead of 20 g polyethylene glycol 400 (PEG-400), and the rest are the same as in Example 1. The finished product is 105.6 g, the content is 90.5%, the liquid phase purity is 99.25% (238 nm), and the yield is 91.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com