Method for producing cleaning oil from coal-tar oil

A coal tar, clean technology, used in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of non-renewable deactivation, inability to maintain long-term catalyst operation, and incomplete utilization of coal tar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0032] The properties of the raw oil used in the examples are shown in Table 1. (wherein wt% is weight percent)

[0033] Table 1 Properties of raw oil

[0034] Raw oil

1#

2#

Density / g·cm -3

1.05

1.12

Distillation range / ℃

128~550

150~600

[0035] Carbon residue, wt%

540

9.80

Mechanical impurities, wt%

0.17

0.22

Sulfur content / ,wt%

0.16

0.35

Nitrogen content, wt%

0.92

1.10

Metal content / μg·g -1

82

152

Oxygen content, wt%

6.20

5.30

Aromatic content, wt%

79.0

82.5

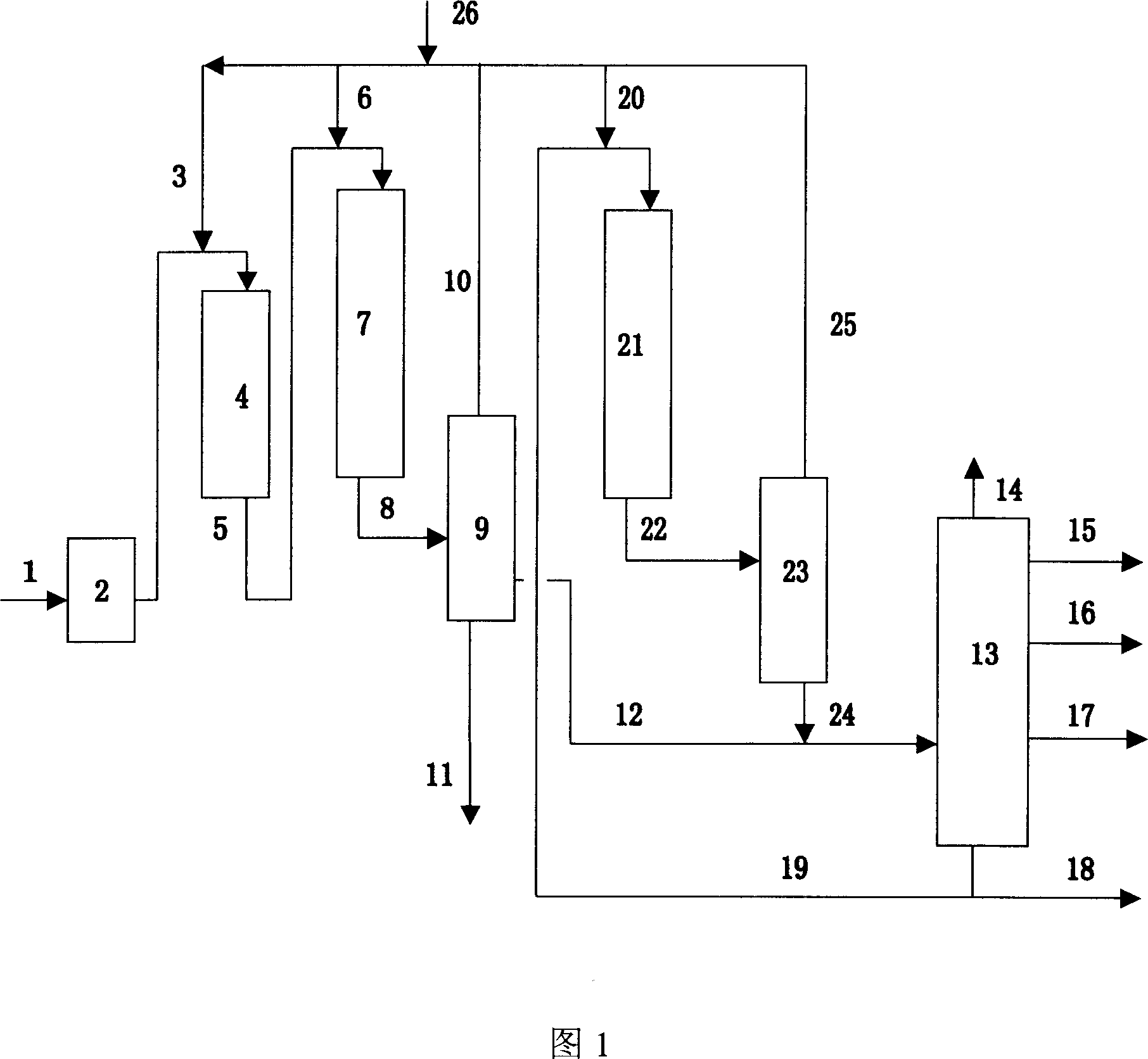

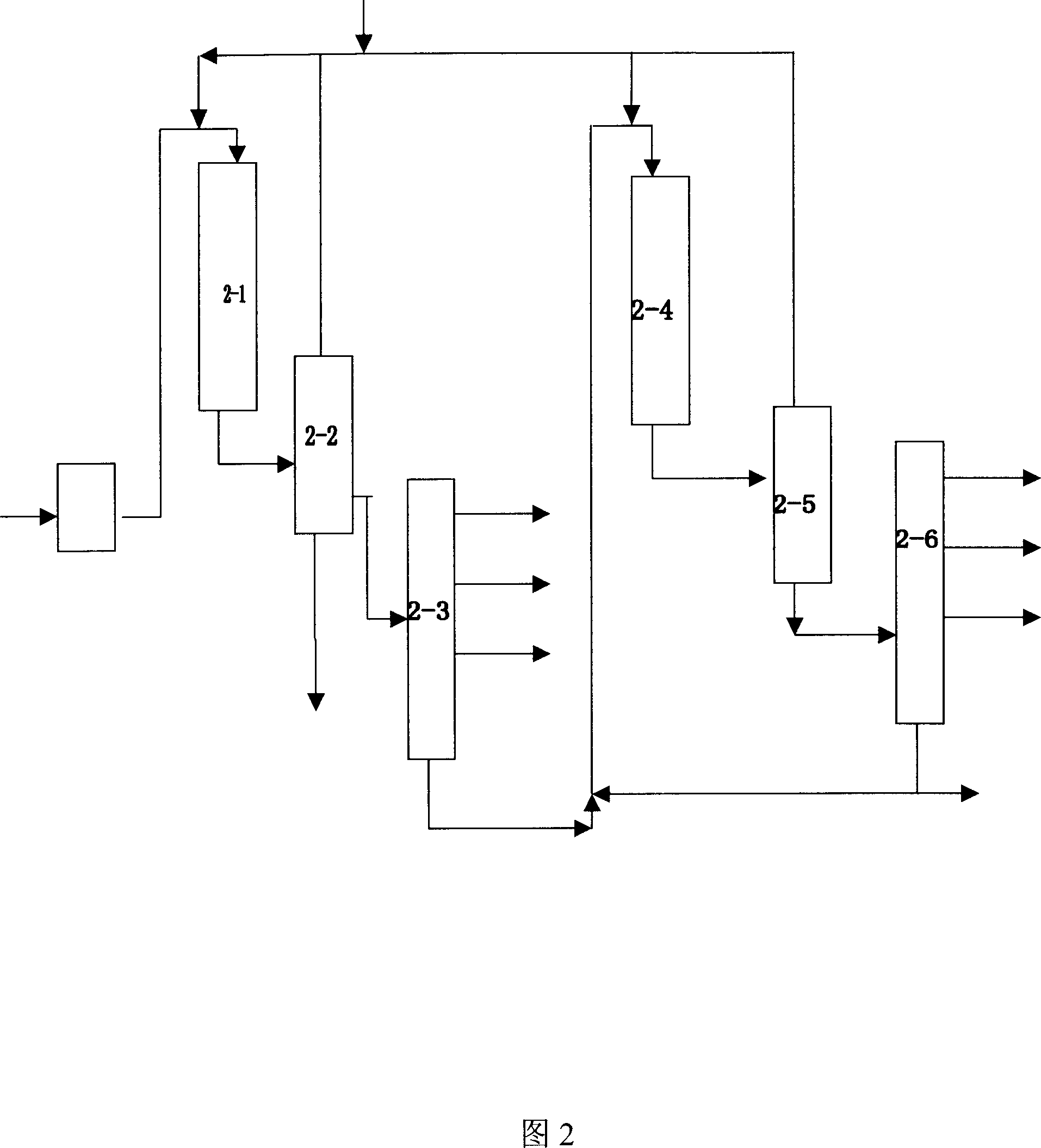

[0036] First, coal tar and hydrogen are mixed into the hydrogenation protection reactor, and then continue to enter the hydrofinishing reactor to obtain the hydrofinishing oil for fractionation, and the tail oil obtained enters the hydrocracking reactor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com