Vehicular weighing digital measurer

A vehicle-mounted weighing and measuring instrument technology, which is applied in the direction of weighing, instruments, and weighing equipment using elastically deformable parts, can solve the problem of inability to realize dynamic measurement of motor vehicles, high production, installation and operation costs, and inconvenient road management and road supervision, to achieve the effects of light weight, low processing and use costs, resistance to temperature and humidity changes, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

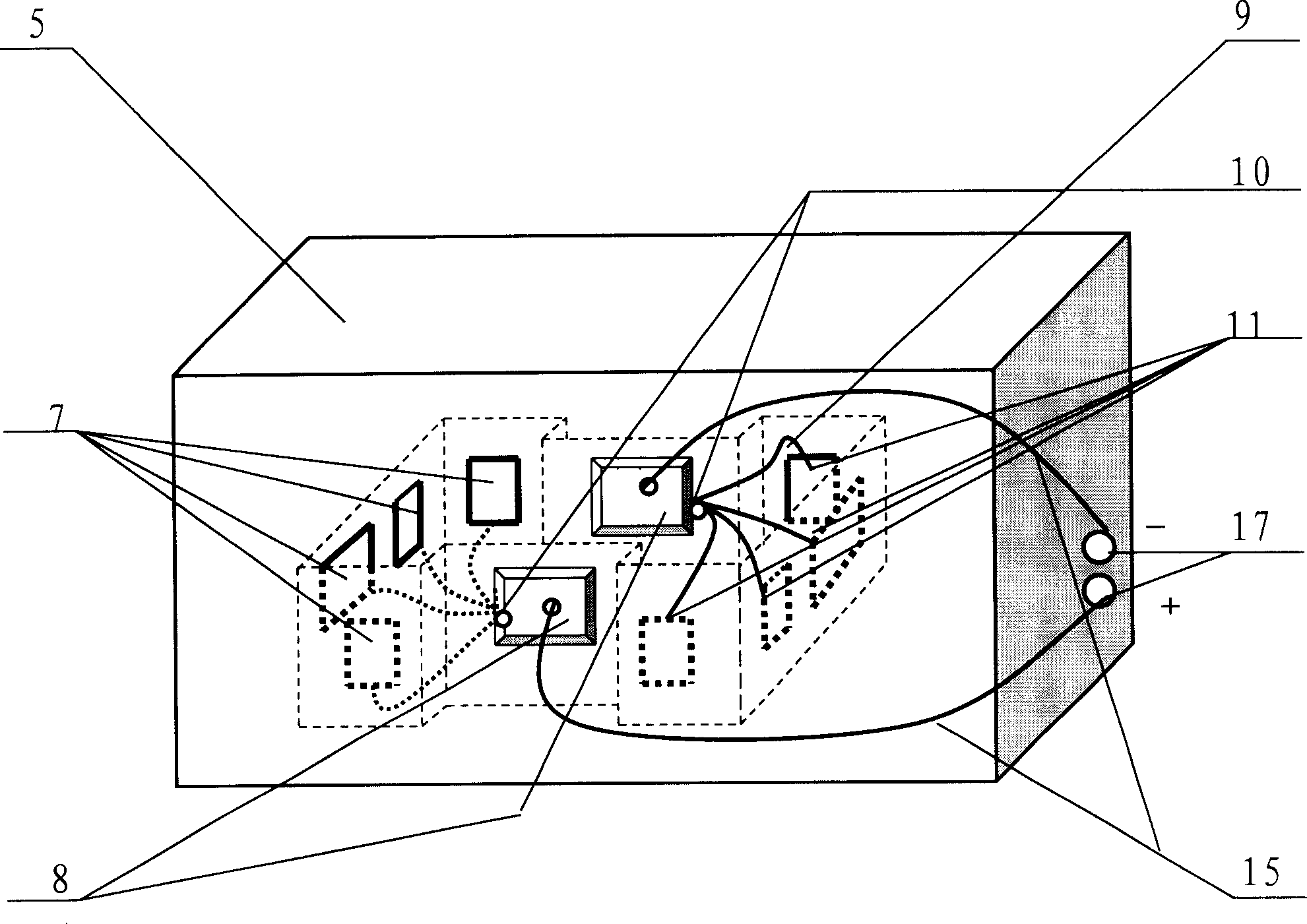

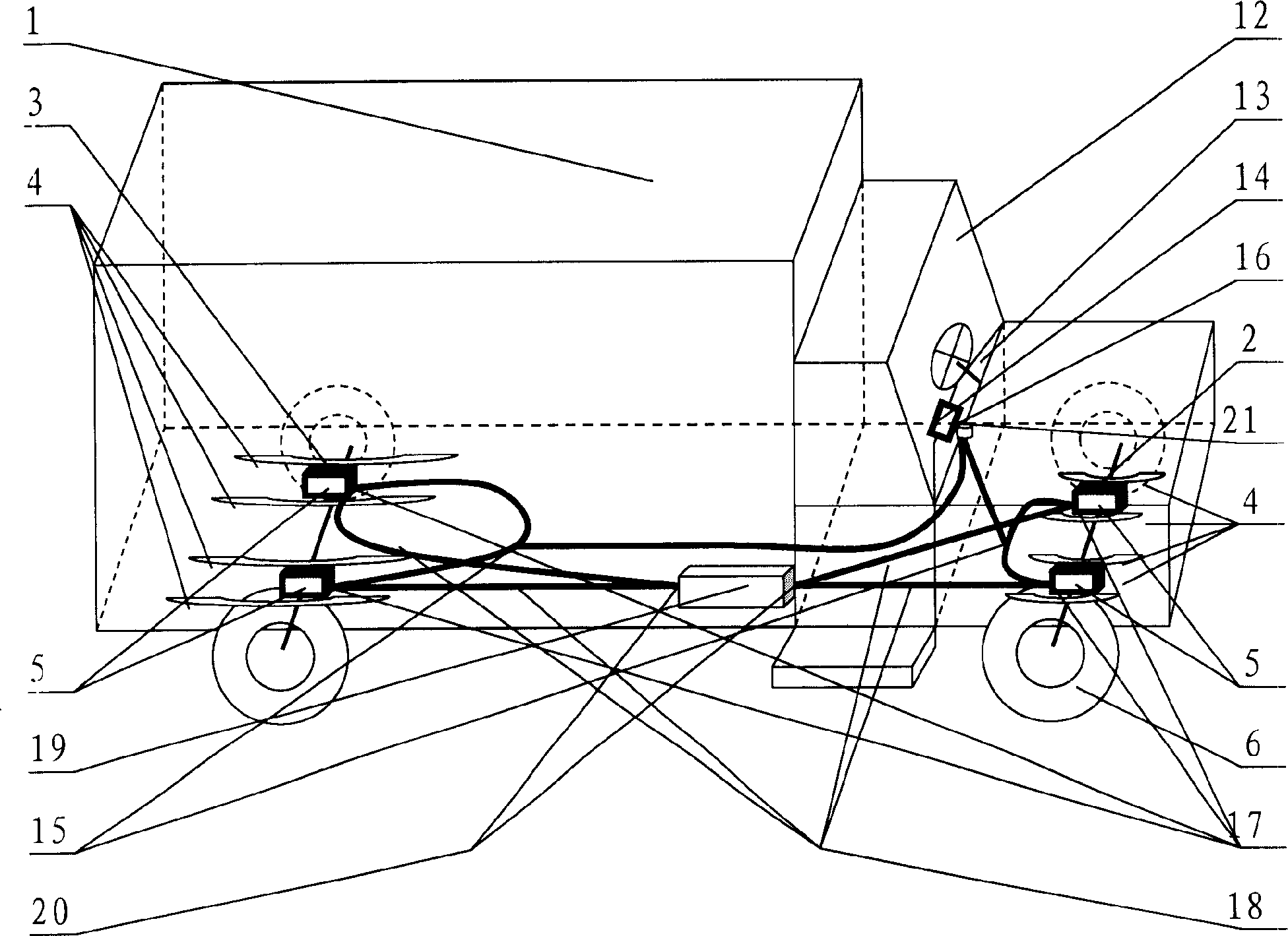

[0009] The technical solution to achieve the purpose of the present invention is: a stress transmission combined weighing sensor device 5 is respectively fixedly connected among the four groups of bridge spring steel plates 4 under the front 2 and under the vehicle body 3 of the motor vehicle 1. The fixed connection can be welding, riveting or bolted connection. In this embodiment, bolted connection is selected, and the whole weight of the four sets of tires 6 from the bottom of the four devices 5 fixedly connected is calibrated as the self-weight of the entire motor vehicle 1. In addition to the skin, a group of metal strain gauge sensing materials 7 that can produce stress transmission effects are closely pasted on the inner surfaces of the four devices 5, and the close pasting can be coupling glue or epoxy resin glue. , the present embodiment selects the coupling glue to be close to each other. At the same time, a group of electronic circuits 8 capable of outputting analog e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com