Indium seal type luminescent screen, and technique for preparing the display tube of using the luminescent screen

A preparation process and fluorescent screen technology, applied in the manufacture of discharge tubes/lamps, tubes/lamp screens, discharge tubes, etc., can solve the problems of low stability, difficult operation, low glass sealing leakage, etc., and achieve high stability Sex and service life, saving time and cost, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

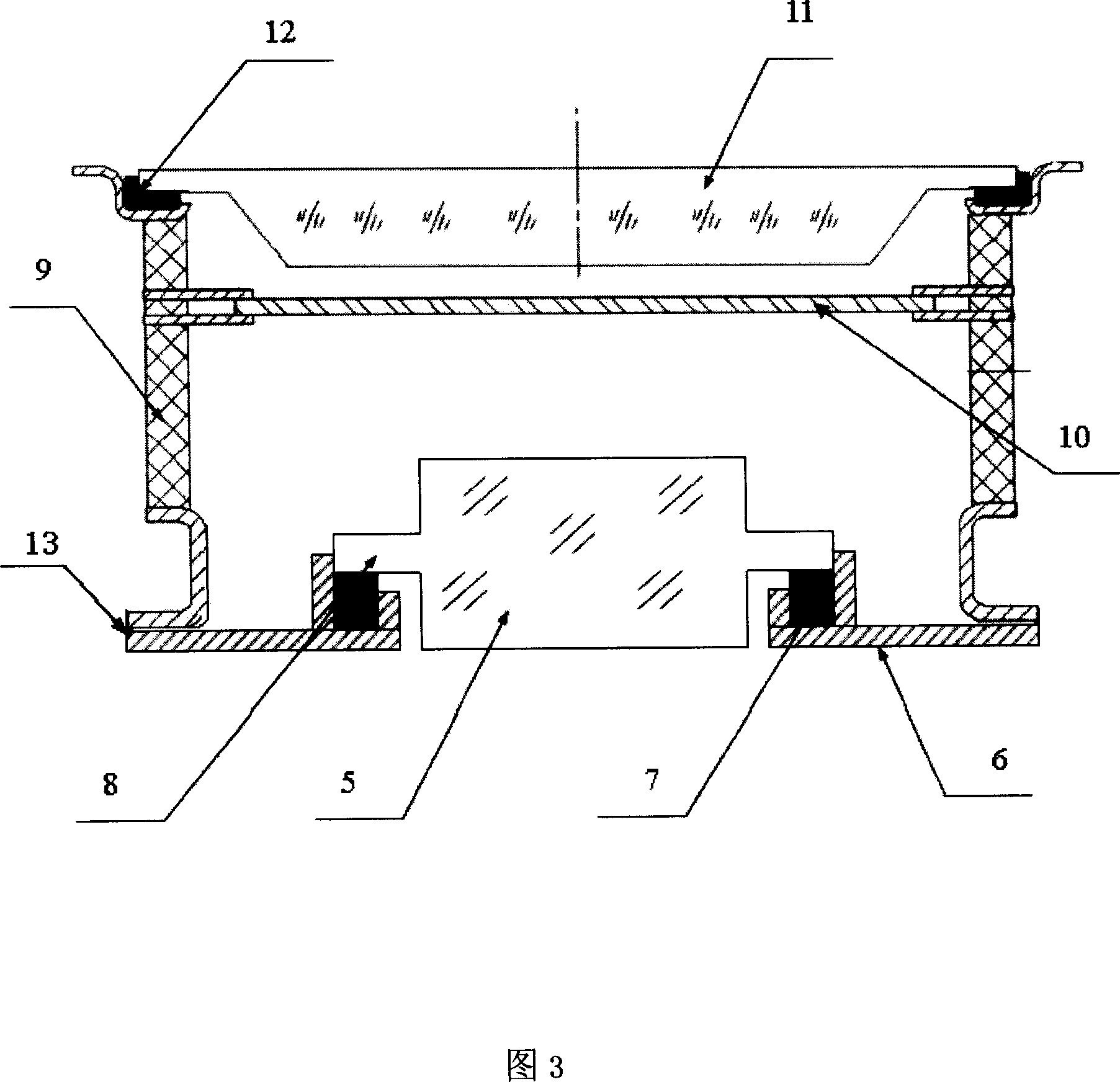

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

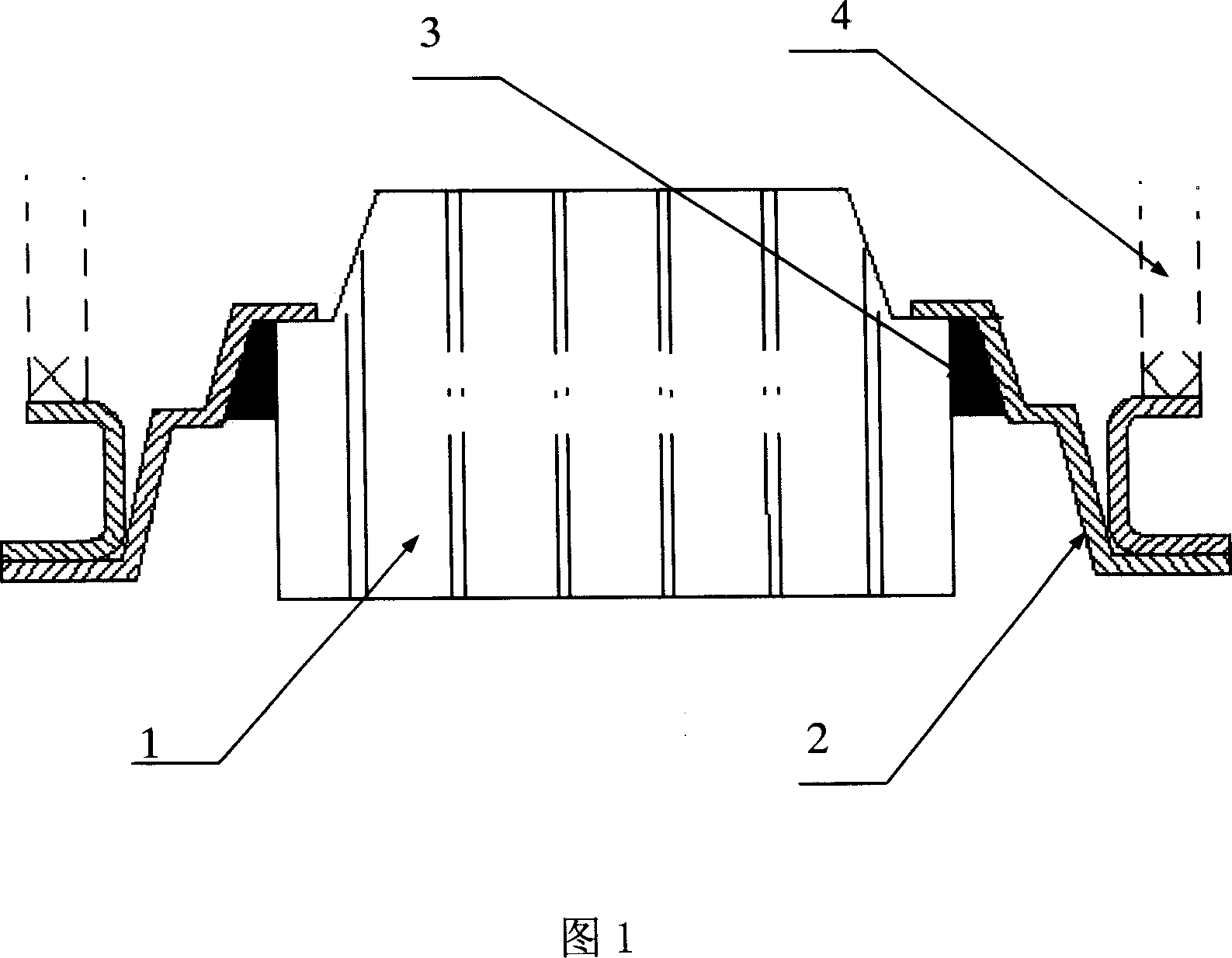

[0015] As shown in Figure 1, in the prior art, the optical fiber panel 1 (fluorescent screen) of the tube and the metal part 2 are sealed with low glass powder. 2 underside. The process procedure is as follows: 1. Coat metal parts with low glass powder, dry at room temperature for more than 10 hours, then melt, and the temperature rises to above 300 degrees within 30 minutes, and then lowers to room temperature for use; 2. Sealing, slow down first. Heat up quickly, then quickly heat up to 450 degrees, and then cool down naturally. Its important disadvantages are the complex process, strict temperature requirements, and the product cannot withstand the stress change of heat conduction and is prone to air leakage, etc., which will not be repeated here.

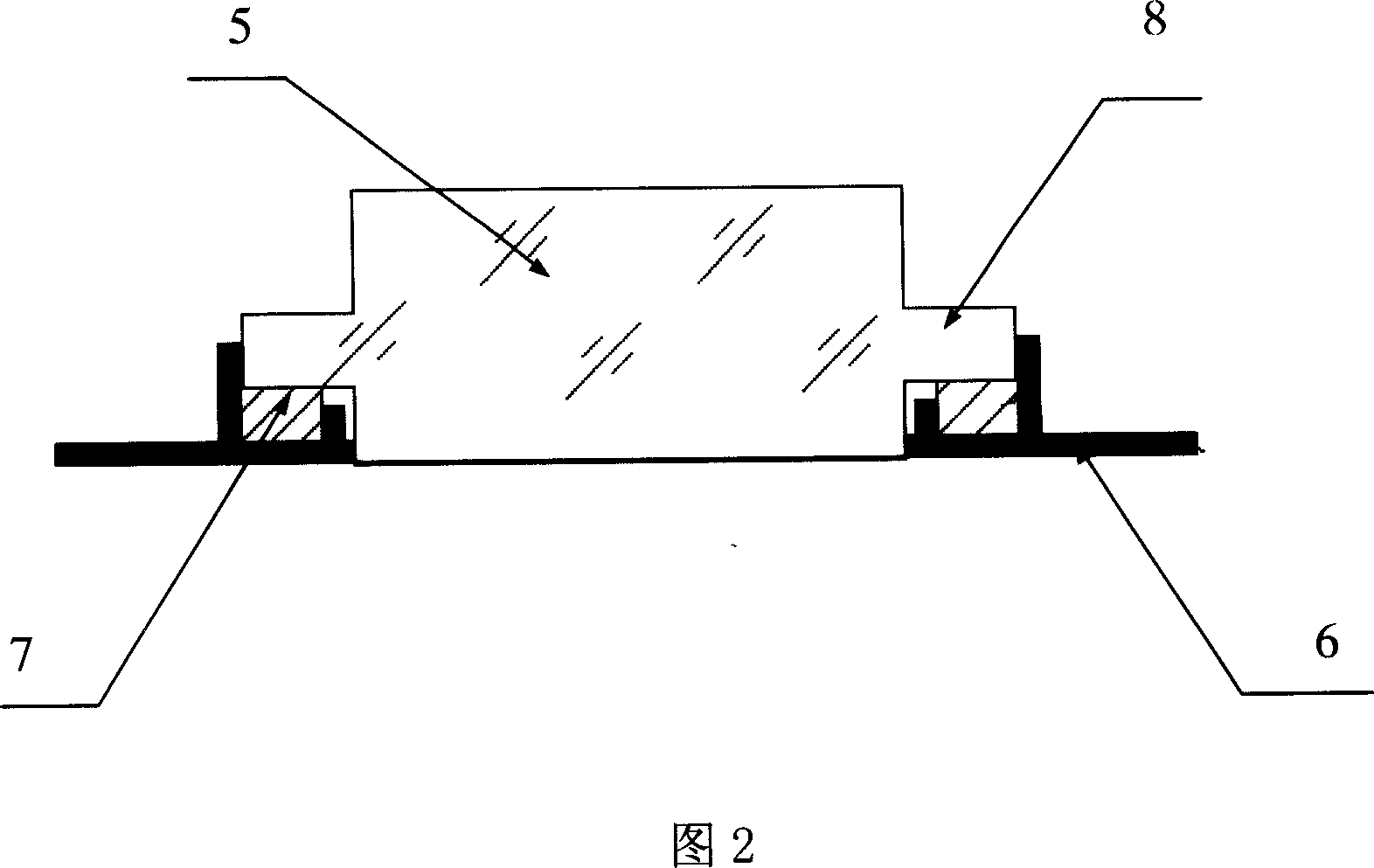

[0016] Fig. 2 is a schematic structural view of the indium-sealed phosphor screen provided by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com