Ultra slow speed, large torsional moment, short magnetic circuit, speed regulation electric motor of heterotype rotor

A speed-regulating motor, high-torque technology, applied in the magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of low speed and high torque, and achieve the starting torque The effect of large, material saving and non-ferrous metal material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

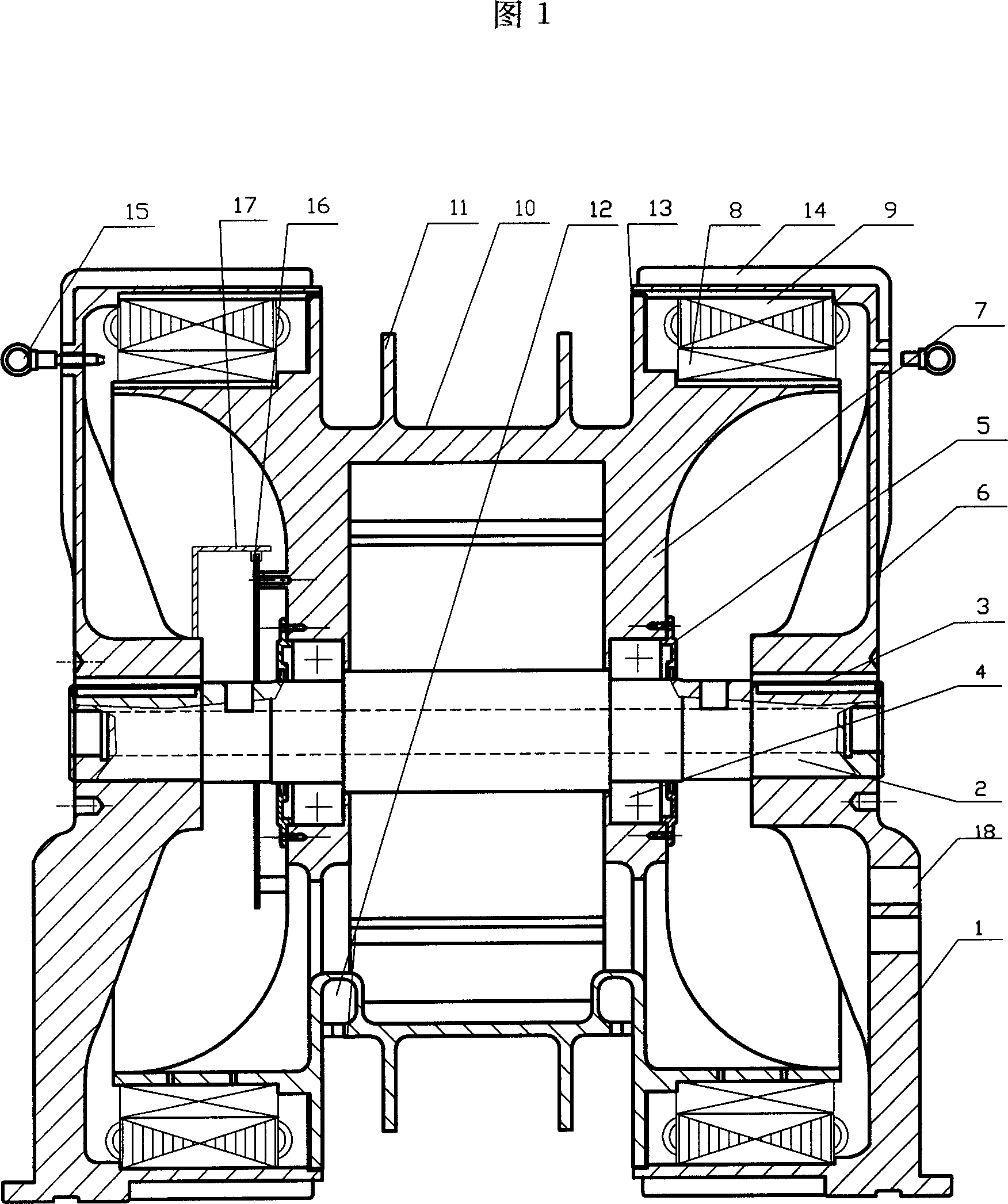

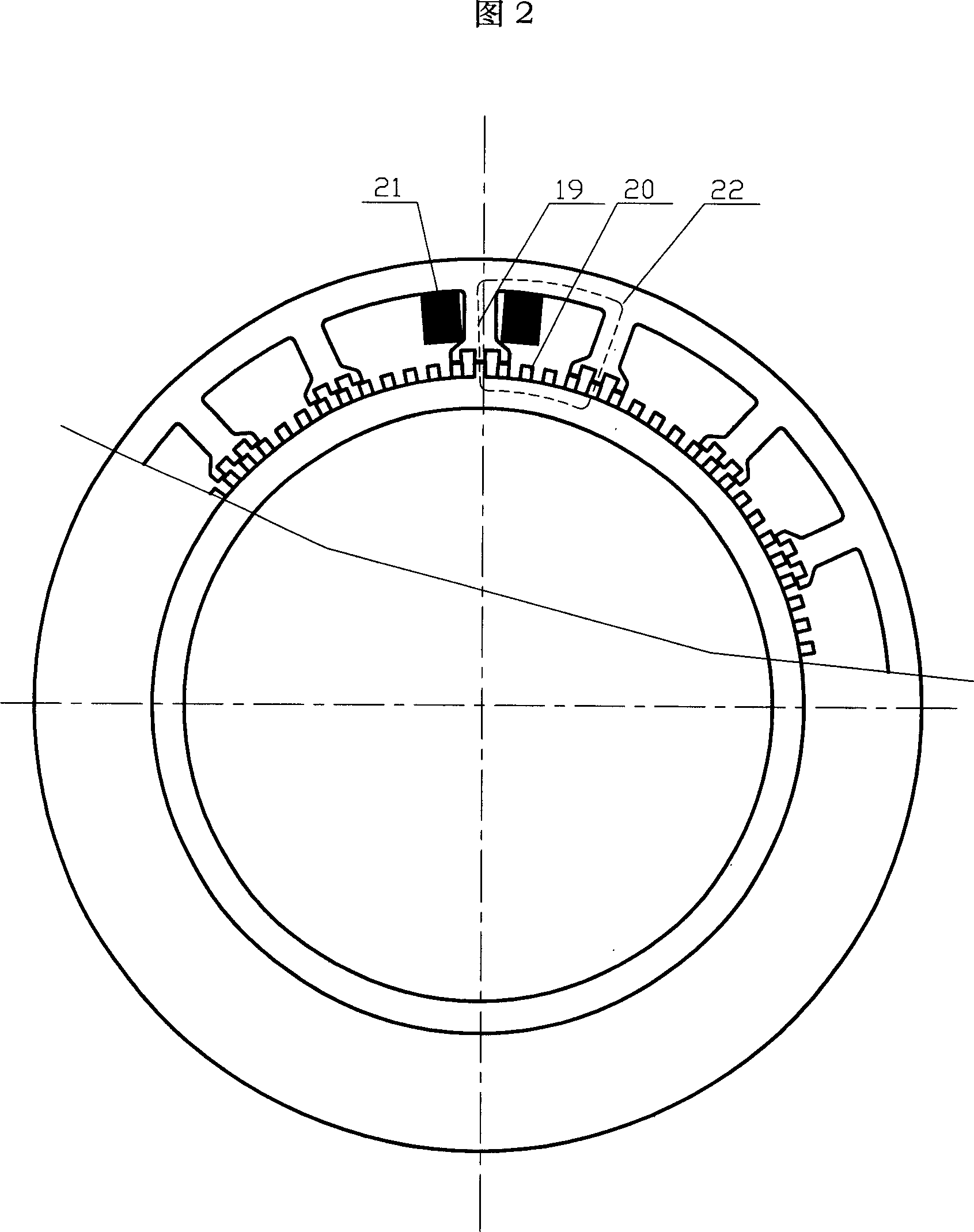

[0047] The special-shaped rotor ultra-low-speed high-torque short-magnetic-circuit speed-regulating motor of the present invention is a drag device designed for "low-speed, high-torque special-shaped motor to drive high-efficiency and low-consumption intelligent pumping unit". The structure is a special-shaped inner rotor ultra-low-speed high-torque short magnetic circuit switch reluctance speed-regulating motor. The special-shaped inner rotor and special-shaped outer stator are casted with cast steel at one time. The maximum outer diameter of the outer stator is ∮1600, and the maximum outer diameter of the inner rotor is ∮1380. With a hollow shaft, the outer stator core adopts a large tooth and three small tooth structure, and the stator and rotor tooth poles adopt "W M Golden combination", that is, four-phase winding 3×16 / 90 or 3×32 / 180, three-phase winding 3×18 / 120. The rated speed of the prototype is 0-20 rpm, the rated torque is greater than 20kNm, and the maximum output p...

Embodiment 2

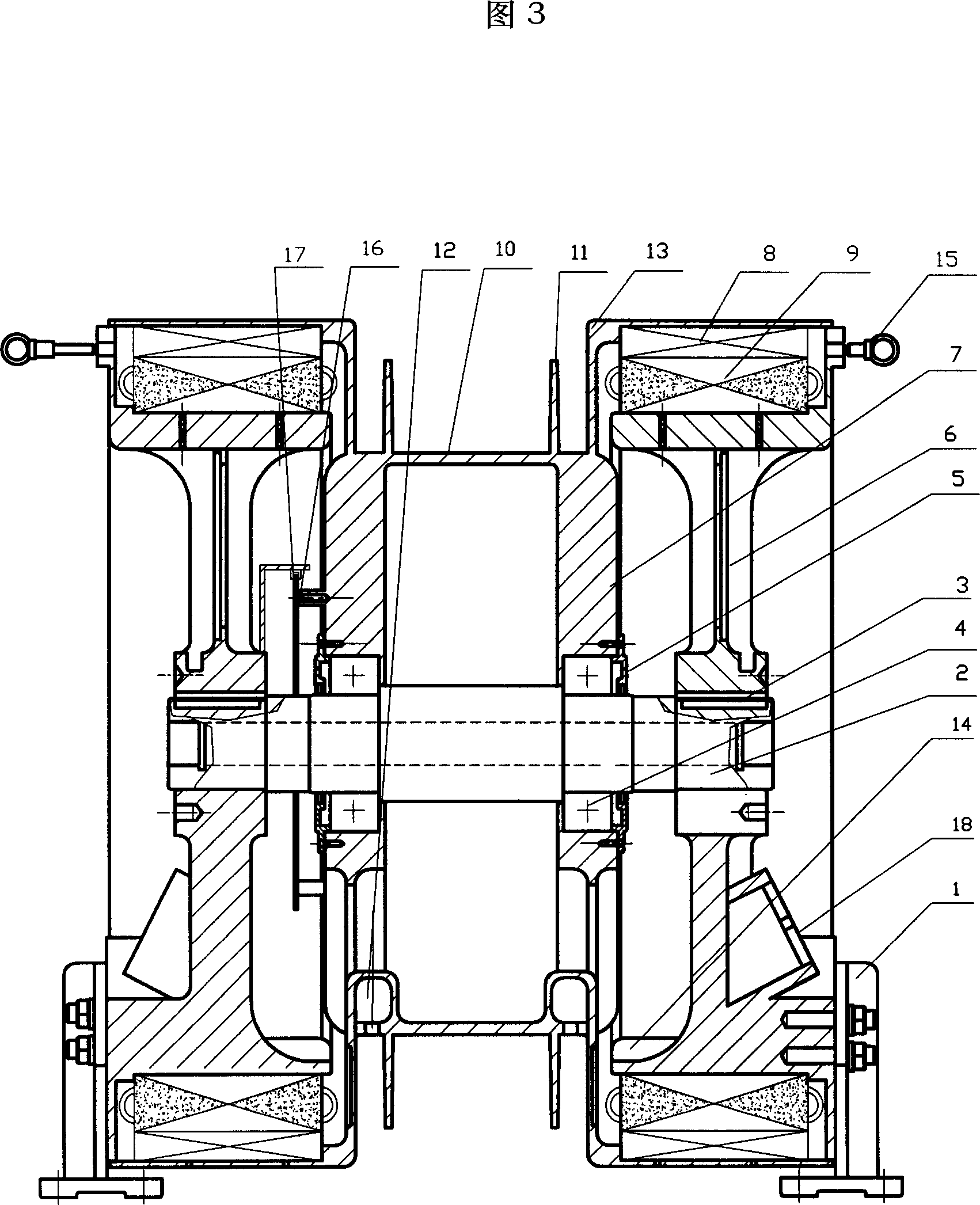

[0049] The special-shaped rotor ultra-low-speed high-torque short magnetic circuit speed-regulating motor of the present invention is also a drag device designed for mechanical oil production of oilfield tubular pumps. The prototype is an ultra-low-speed high-torque permanent-magnet speed-regulating motor with a special-shaped outer rotor structure. The special-shaped outer rotor and special-shaped inner stator shell are casted with cast steel at one time, and the outer rotor shell and the teeth are shielded with non-magnetic stainless steel. The maximum diameter of the outer rotor is ∮1412, the maximum outer diameter of the inner stator is ∮1210, and the main shaft is a hollow shaft. The rated speed of the prototype is 0-50 r / min, the rated torque is greater than 16kNm, and the maximum output power is 22kW, which is suitable for driving a Type 10 pumping unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com