Column type short flow reverse floatation process and apparatus for hematite

A short-process, reverse flotation technology, applied in flotation, magnetic separation, solid separation, etc., can solve the problems of high operating costs, large power consumption, and large maintenance, and achieve low operating costs and low power consumption , small floor space and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

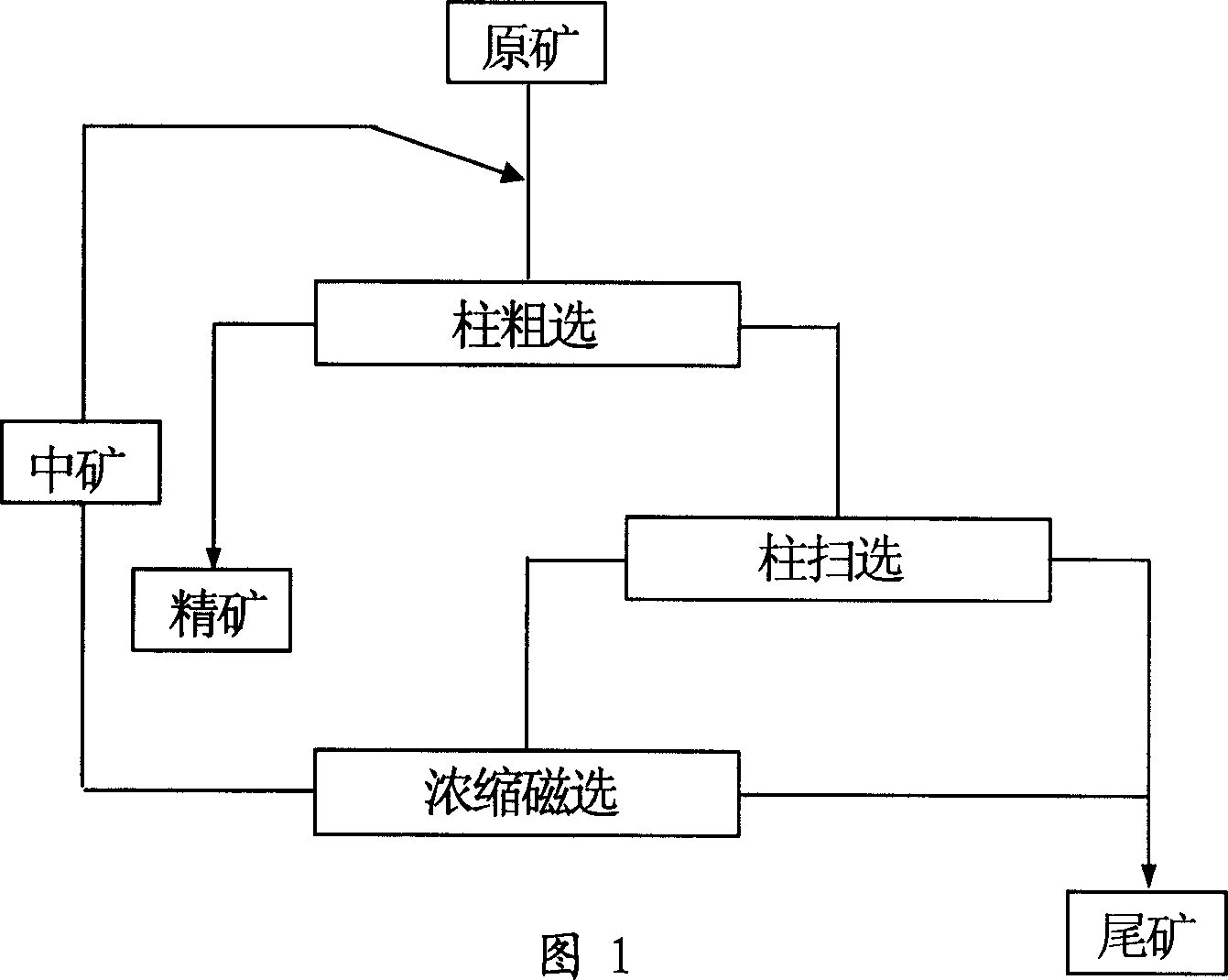

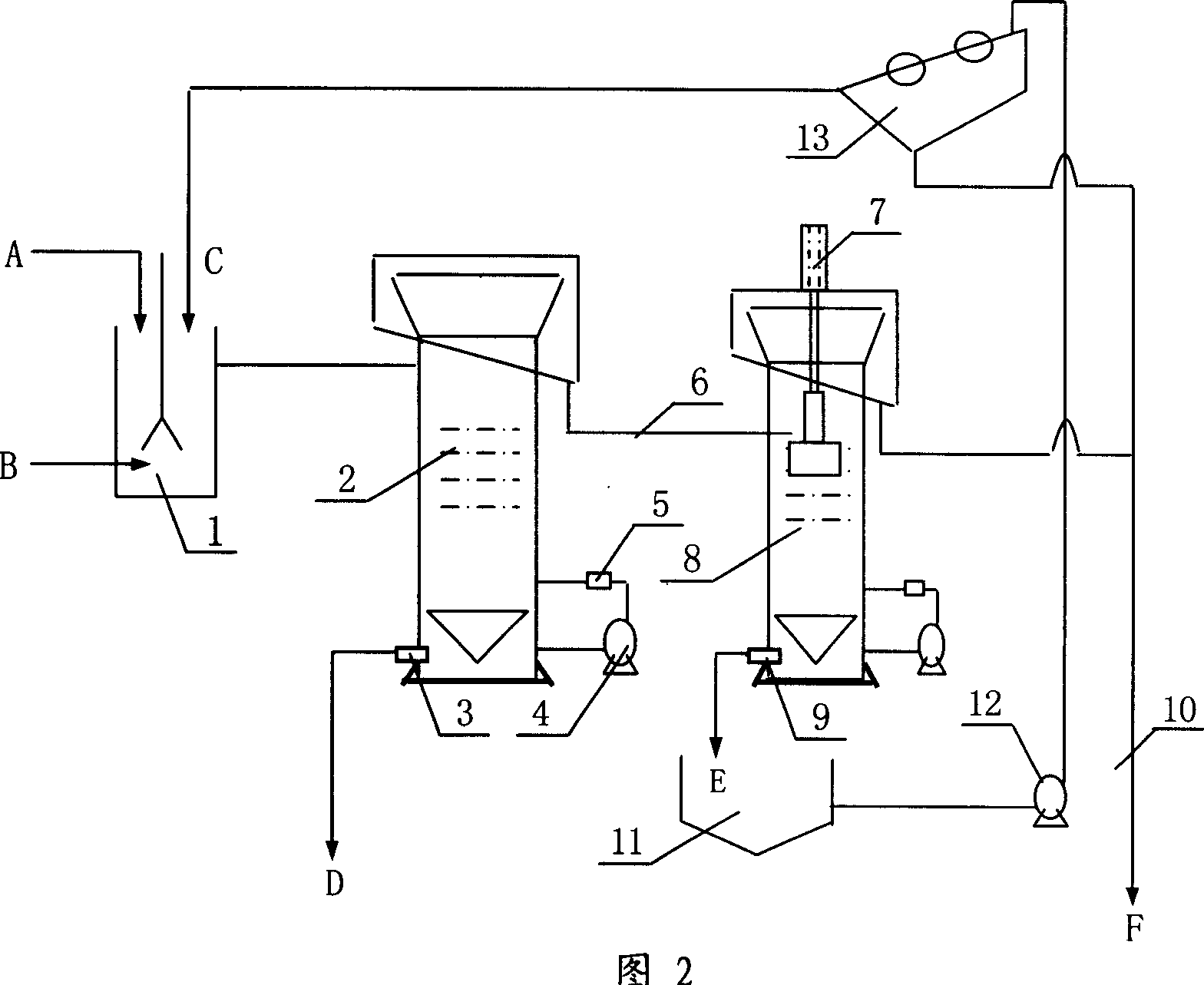

[0017] As shown in Figures 1 and 2, the hematite column type short-flow reverse flotation process of the present invention first feeds the raw ore B and the flotation agent A into the pulp mixing tank 1 together, and proceeds through the impeller in the pulp mixing tank 1 Stirring, the stirring time is 10-15 minutes, and the mass percent concentration of the flotation feed material formed by the stirring is 35%-45%. The flotation feed material flows from the pulp mixing tank 1 to the rougher flotation column 2, and is roughed under the action of the bubble generator 4 and the circulation pump 5, and the rougher concentrate D is discharged from the bottom outlet 3 of the rougher flotation column , the concentrate is a qualified hematite concentrate product; the foam in the upper layer of the roughing flotation column 2 is transported to the scavenging flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com