Glass lens processing equipment and method

A plastic lens and processing device technology, applied in metal processing, other household appliances, optical components, etc., can solve the problems of easy dust generation, increased cleaning costs, and easy adsorption of dirt, so as to reduce production costs, reduce cleaning difficulty and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

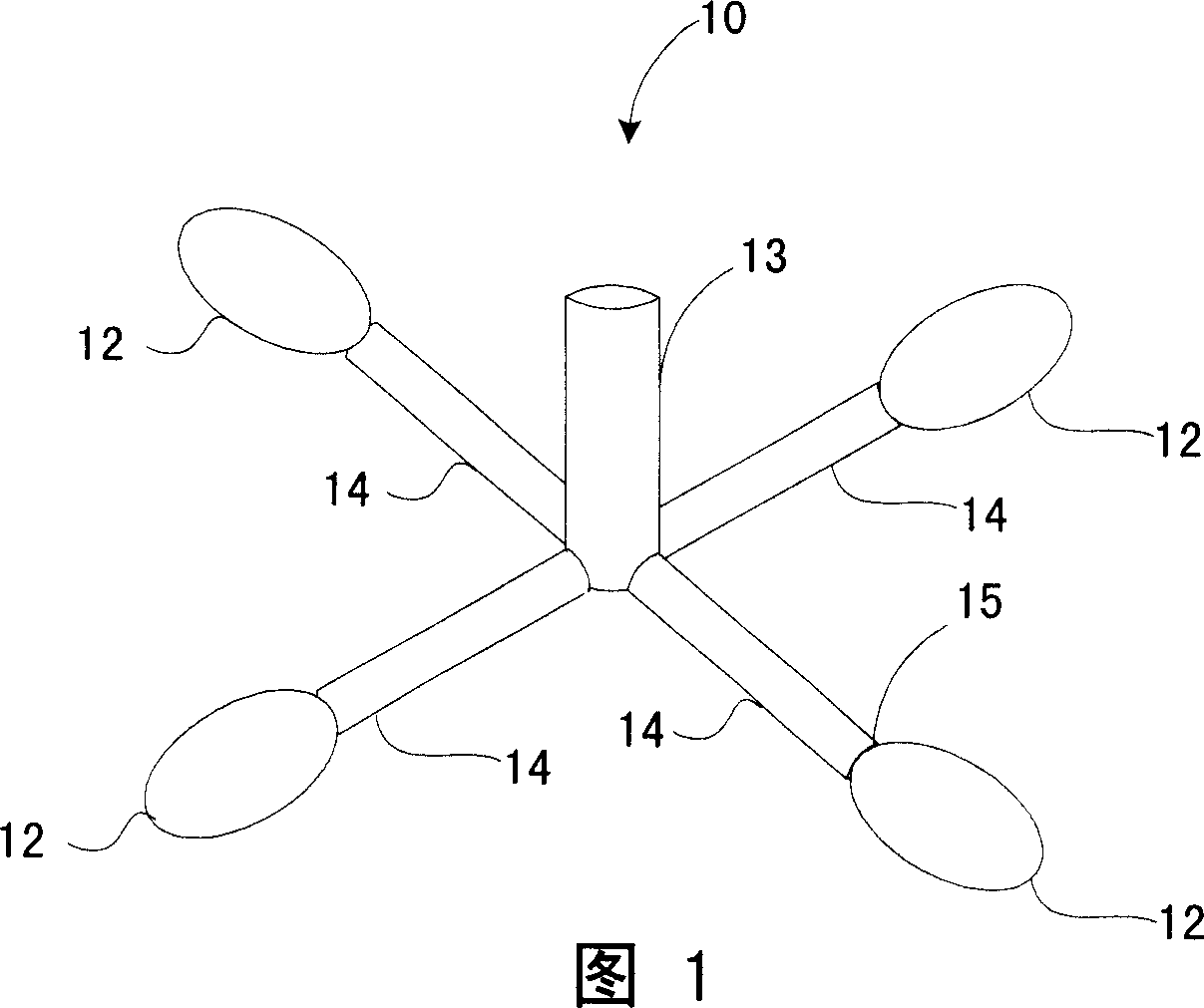

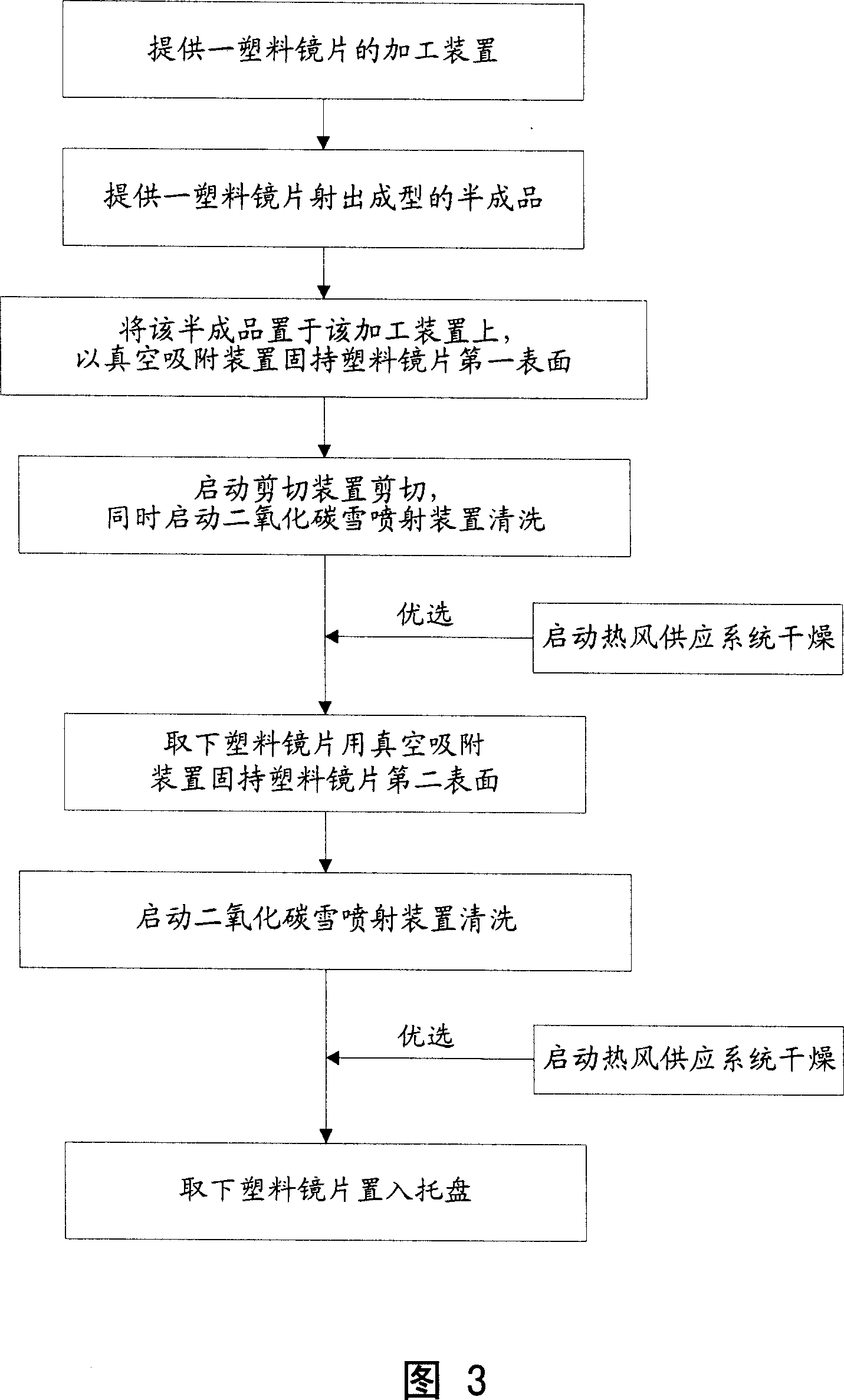

[0013] The processing device and method of the above-mentioned plastic lens will be described in detail below with reference to the accompanying drawings and embodiments.

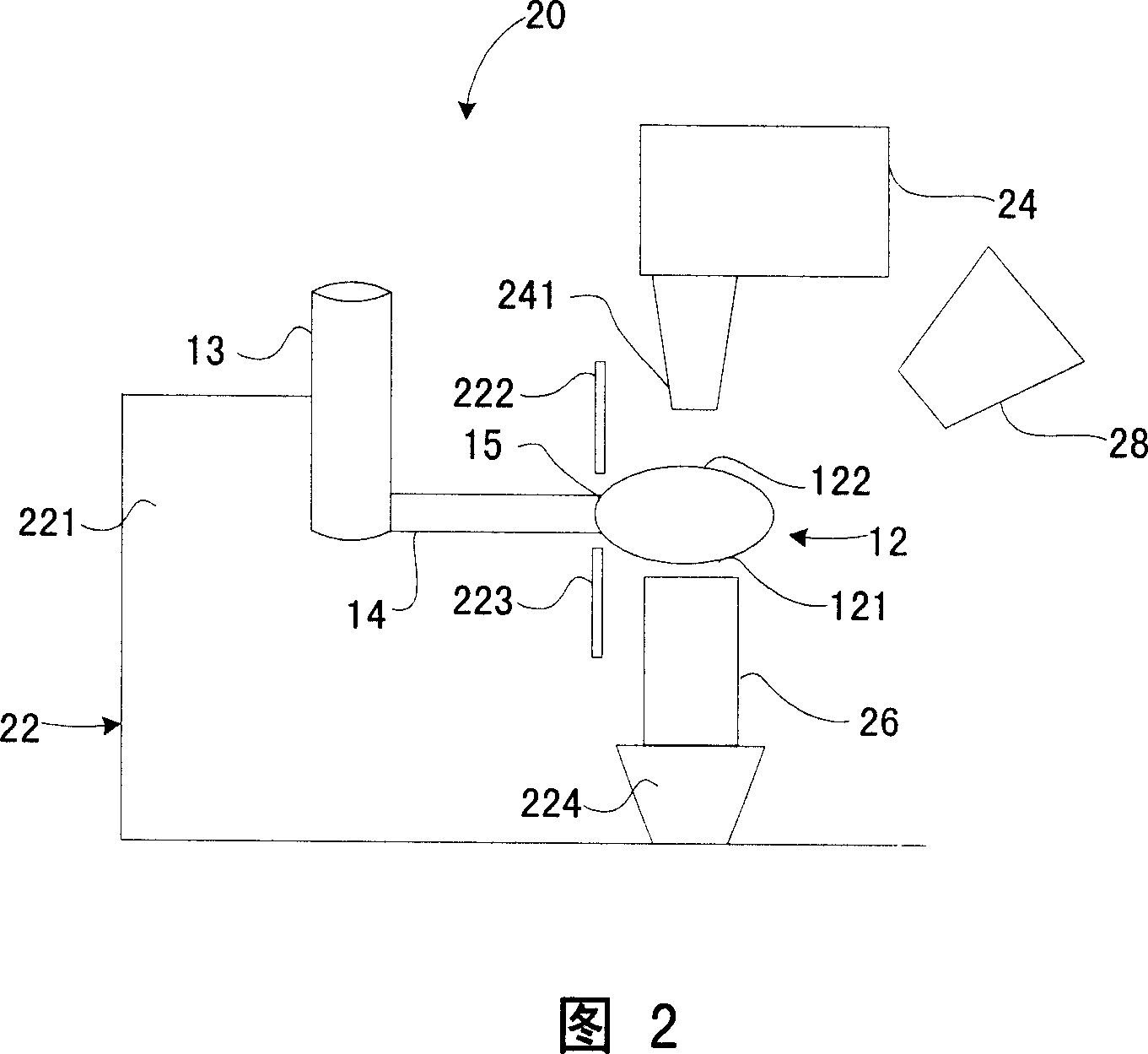

[0014] Please refer to FIG. 2, this embodiment provides a processing device 20 for plastic lenses. The device 20 includes a shearing device 22, a carbon dioxide snow spray device 24, and a vacuum adsorption device 26. Preferably, a hot air supply system 28 may also be included. The cutting device 22 includes a main body 221, an upper cutting knife 222, a lower cutting knife 223, and a supporting base 224. The upper shearing knife 222, the lower shearing knife 223, and the supporting base 224 are all located on the main body portion 221, and the vacuum suction device 26 is located on the supporting base 224 of the cutting device 22. It can be a vacuum suction head because it has a vacuum inside. The suction cup and the vacuum generator can automatically and firmly hold the plastic lens 12 when it is in the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com