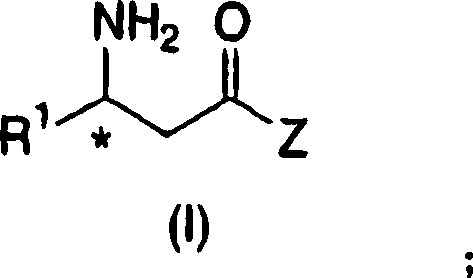

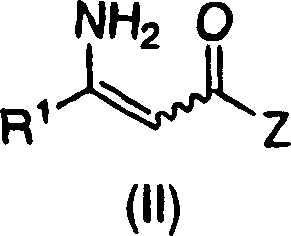

Process for the preparation of enantiomerically enriched beta amino acid derivatives

An enantiomer, alkyl technology, applied in the field of β-amino acid derivatives, can solve problems such as synthesis difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0230]

[0231] (2R)-4-oxo-4-[3-trifluoromethyl-5,6-dihydro[1,2,4]triazolo[4,3-a]pyrazine-7(8H)- base]-1- (2,4,5-trifluorophenyl)butane-2-amine (2-5)

[0232] Preparation of 3-(trifluoromethyl)-5,6,7,8-tetrahydro[1,2,4]triazolo[4,3-a]pyrazine hydrochloride (1-4)

[0233] plan 1

[0234]

[0235] Step A: Preparation of bishydrazide (1-1)

[0236] Hydrazine (20.1 g, 35 wt% in water, 0.22 mol) was mixed with 310 mL of acetonitrile. 31.5 g of ethyl trifluoroacetate (0.22 mol) were added within 60 minutes. The internal temperature increased from 14°C to 25°C. The resulting solution was aged at 22-25°C for 60 minutes. The solution was cooled to 7°C. At a temperature below 16°C, 17.9 g of a 50 wt% aqueous NaOH solution (0.22 mol) and 25.3 g of chloroacetyl chloride (0.22 mol) were added simultaneously within 130 minutes. When the reaction was complete, the mixture was vacuum distilled at 27-30°C under a vacuum of 26-27 Hg to remove water and ethanol. During th...

Embodiment 2

[0287]

[0288] (2R)-4-oxo-4-[3-(trifluoromethyl)-5,6-dihydro[1,2,4]triazolo[4,3-a]pyrazine-7(8H )-base]-1- (2,4,5-trifluorophenyl)butane-2-amine (2-5)

[0289]

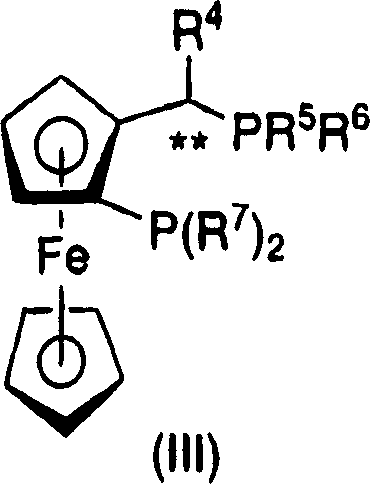

[0290] Bis(norbornadiene) rhodium(I) tetrafluoroborate {[Rh(nbd) 2 ] BF 4} (41.55mg, 0.1mmol), ligand D (69.73mg, 0.1mmol) and enaminoamide 2-4 (45 g, 111.1 mmol) into the flask. To this mixture was added 37.5 mL of a solvent mixture of methanol (very dry and degassed) and 112.5 mL of 2,2,2-trifluoroethanol (distilled and degassed). The slurry was then transferred to a stainless steel autoclave under nitrogen and sealed. The autoclave was then heated to 50°C and pressurized to 500 psig with hydrogen. Analysis of a sample taken after 17 hours using HPLC confirmed that the reaction was complete giving 94% assay yield and 94% ee.

Embodiment 3-5

[0292]

[0293] Table 1 a

[0294] Example

Ligand

metal precursor

%Yield b

%ee c

structure

3

4

5

A

B

C

[Rh(cod) 2 ] BF 4

[Rh(cod)Cl] 2

[Rh(cod)Cl] 2

77

58

15

88

76

78

R

R

S

[0295] a: Reaction conditions: 5 mol% metal precursor, 5 mol% ligand, 90 psig H in TFE 2 , 50°C, 18 hours;

[0296] b: Tested by HPLC; c: AS-RH chiral column eluted with 20% acetonitrile / water as mobile phase, tested by chiral HPLC

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com