Artificial plate of tourmaline and its making process

A technology of tourmaline and tourmaline powder, which is applied in the field of tourmaline artificial stone slabs and its preparation, can solve the problems of storage and construction safety hazards of falling objects, construction difficulty and construction cost, and increased wall load. Bright quality, strong plasticity, warm cell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

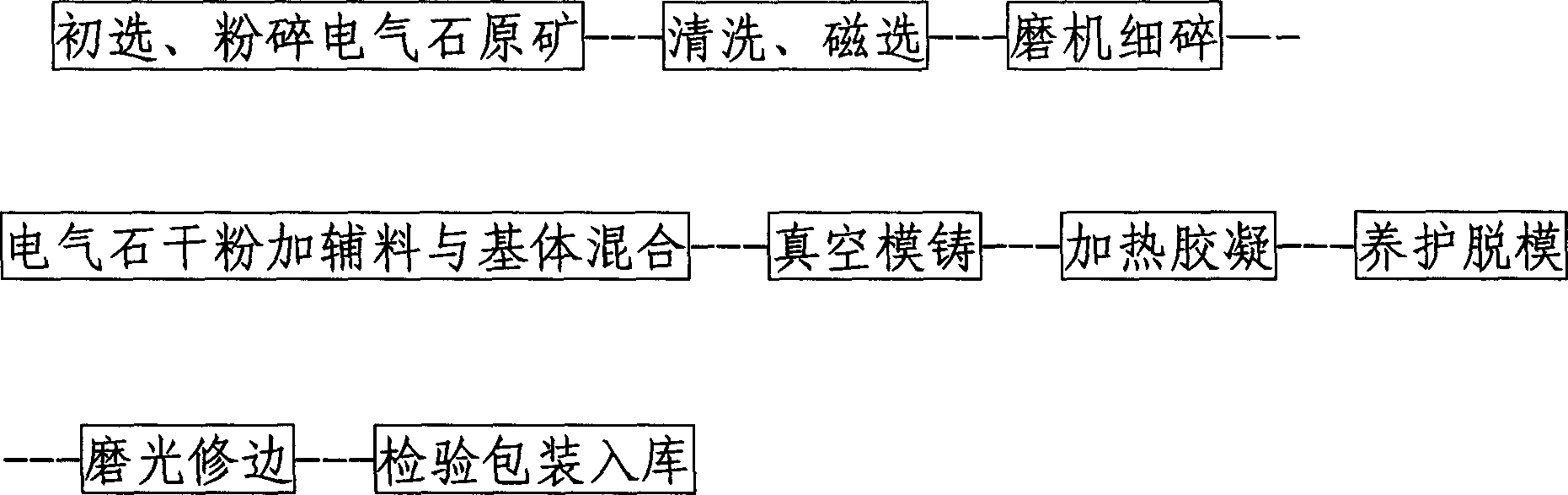

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of tourmaline man-made plate, it is made up of following components by weight percentage: take 45% unsaturated polyester resin (UPR) as matrix, add aluminum hydroxide (ore powder), color paste, Flame retardant and T8 colorless accelerator auxiliary materials and 50% tourmaline powder are used as fillers to make tourmaline negative ion far-infrared resin boards.

Embodiment 2

[0027] Embodiment 2: a kind of tourmaline man-made plate, it is made up of following component by weight percentage: take 55% methyl methacrylate (MMA) as matrix (being commonly called as acrylic, plexiglass) aluminum hydroxide (ATH), color paste, flame retardant and T8 colorless accelerator auxiliary materials and 40% tourmaline powder are used as fillers to make tourmaline anion far-infrared acrylic boards.

Embodiment 3

[0028] Embodiment 3: a kind of tourmaline artificial plate, it is made up of the following components by weight percentage: take the mixture of 50% methyl methacrylate (MMA) and unsaturated polyester resin (UPR) as matrix and add Aluminum hydroxide, color paste, flame retardant, T8 colorless accelerator auxiliary materials and 45% tourmaline powder are used as fillers to make tourmaline negative ion far-infrared composite acrylic board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com