Titanium alloy anode for electrolyzing manganese dioxide and its making process

A technology for electrolytic manganese dioxide and a manufacturing method, which is applied to electrodes, electrolytic processes, electrolytic components, etc., can solve problems such as cell voltage rise, anode cell voltage rise, cracking and delamination, etc., to improve product quality, reduce and stabilize The effect of increasing the cell voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

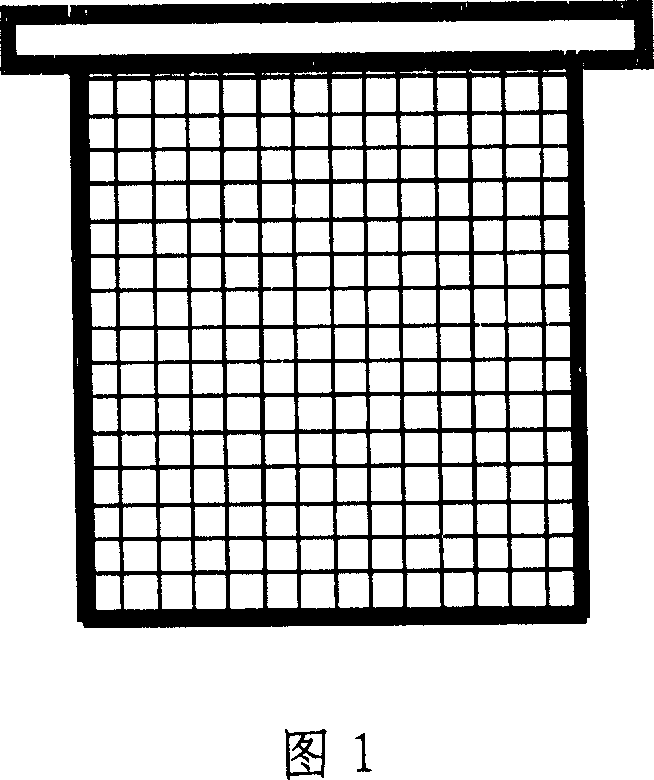

[0015] The ingredients in titanium are: 8%Mn+3%Al+1%Zr, mixed and pressed into consumable electrodes, melted into ingots in a vacuum electric arc furnace for the second time, and then processed into φ5mm wire rods, as shown in Figure 1 Assembled into an anode, and use 100A / m under normal industrial conditions 2 The current density is electrolytic manganese dioxide, the cell voltage can be stabilized within 2.8 volts to 3.3 volts, and the appearance of the product is good.

Embodiment 2

[0017] The ingredients in titanium are: 4%Mn+8%Cr+1%Zr+3%Al, mixed and pressed into consumable electrodes, secondly smelted into ingots in a vacuum electric arc furnace, and then processed into φ3mm wire rods , assembled into an anode according to Figure 1, and use 80A / m under normal industrial conditions 2 The current density is electrolytic manganese dioxide, the cell voltage can be stabilized within 2.3-3.0 volts, and the appearance of the product is good.

Embodiment 3

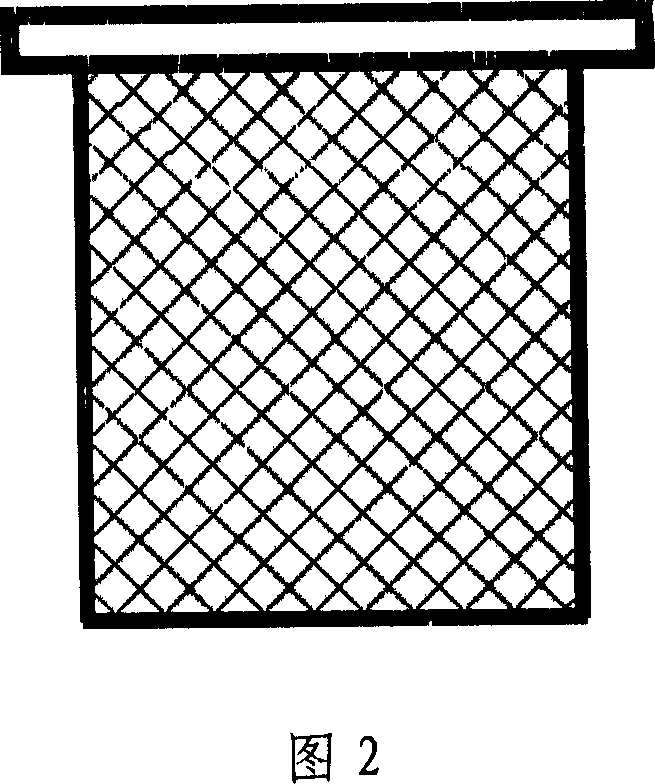

[0019] The ingredients in titanium are: 6%Mn+5%Cr+3%Al, mixed and pressed into consumable electrodes, smelted into ingots in a vacuum electric arc furnace, and then processed into φ2.5mm wire rods, according to Figure 2 is assembled into an anode, and 50A / m is used under normal industrial conditions 2 The current density is electrolytic manganese dioxide, the cell voltage can be stabilized within 1.8-2.2 volts, and the appearance of the product is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com