Heat transfer apparatus, cooled electronic module and fabrication methods thereof

An electronic module and cooled technology, applied in cooling/ventilation/heating transformation, instrument cooling, circuit, etc., can solve problems such as interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

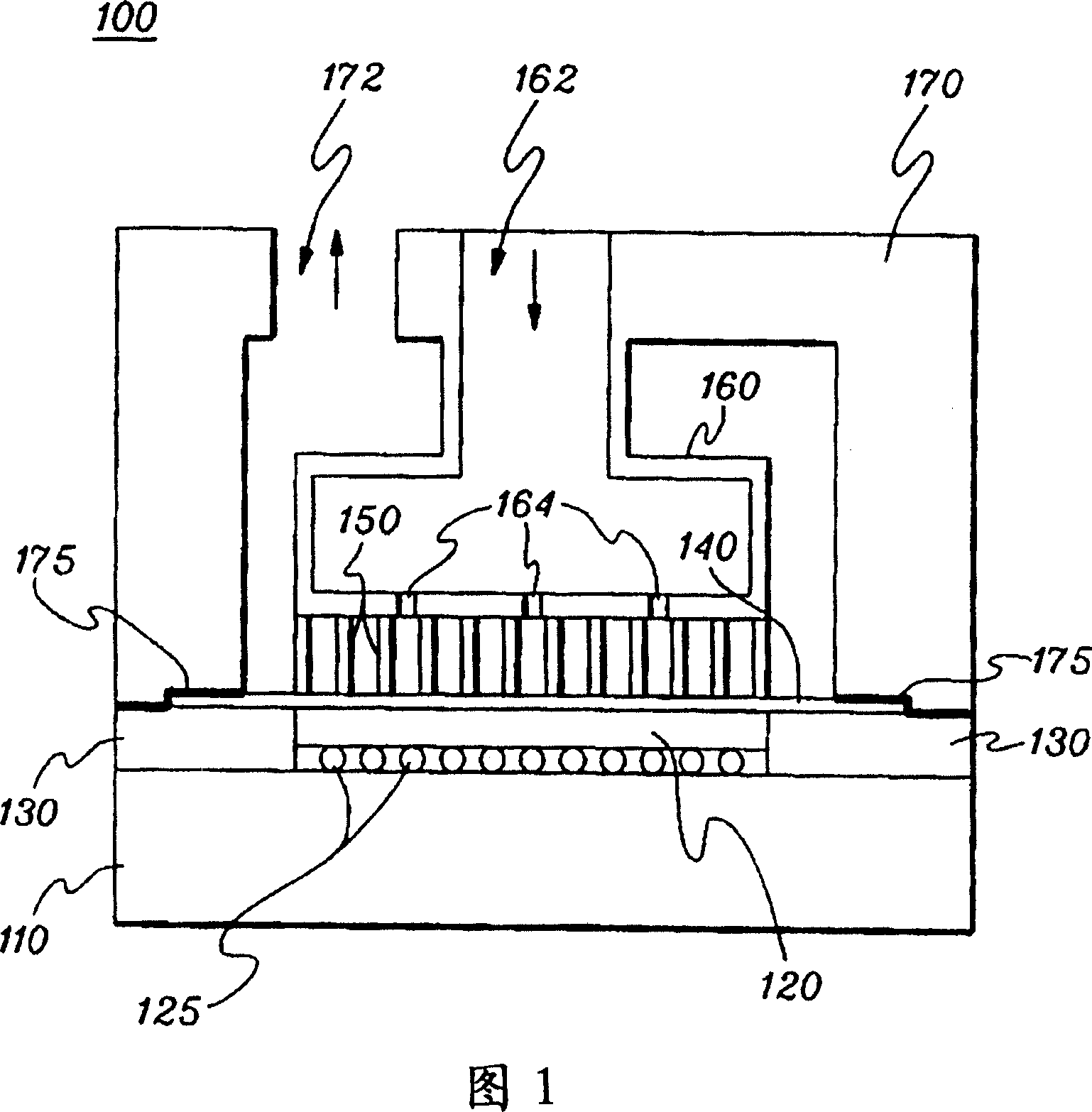

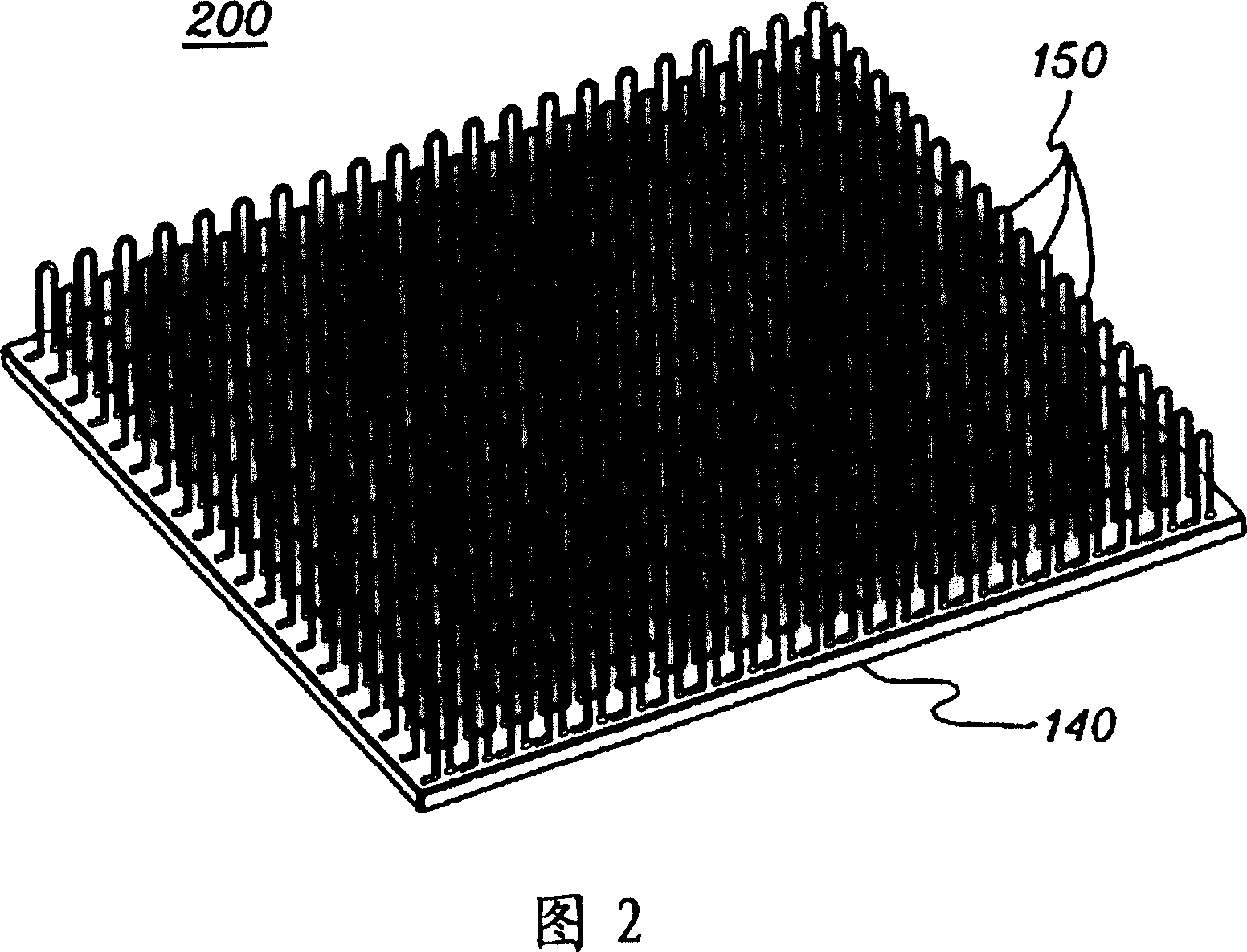

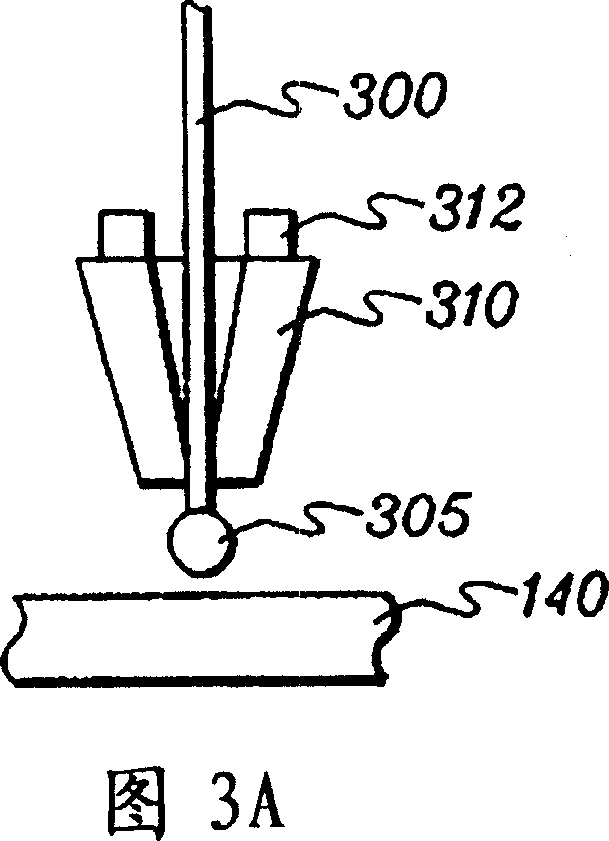

[0034] As used herein, "electronic equipment" includes any heat-generating electronic component of a computer system or other electronic system that requires cooling. In one example, an electronic device includes an integrated circuit chip. The term "cooled electronic module" includes any electronic module with a cooling function and at least one electronic device, and both single-chip modules and multi-chip modules are examples of electronic modules to be cooled. As used herein, "micro cooling structure" refers to a cooling structure with a feature size of 200 microns or less. A "composite" fin structure refers to any fin in which a first material having a first thermal conductivity is coated or wrapped with a second material having a second thermal conductivity. Each "material" may be a thermally conductive element or compound.

[0035] In general, there is provided an improved cooling device and method of making the same, which uses direct or indirect liquid coolant metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com