Method for cracking source oven molecular beam epitaxial indium phosphide using solid-state phosphorus

A technology of molecular beam epitaxy and source solution furnace, which is applied in the direction of chemical instruments and methods, polycrystalline material growth, and chemically reactive gases, and can solve problems such as beam current drop, substrate loss of phosphorus pressure protection, and waste of phosphorus sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

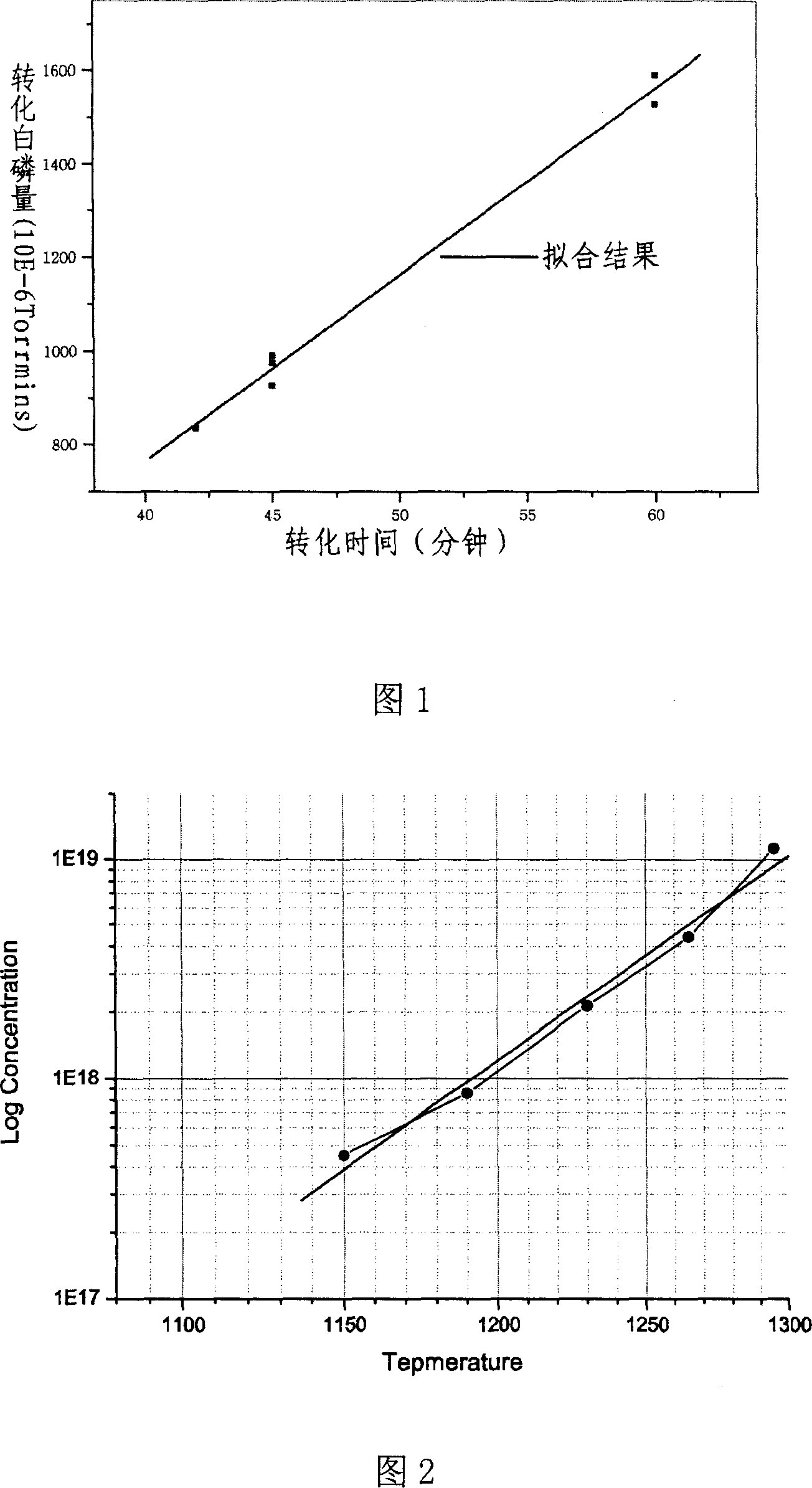

[0024] The present invention uses the 500cc fourth-generation phosphorus cracking source furnace (500cc Mark IV Phosphorus Valved Cracker Effusion Cell) in a Veeco Mod GEN II molecular beam epitaxy system as an example to demonstrate the conversion of desirable white phosphorus Quantitative method.

[0025] The steps involved in this method are as follows:

[0026] 1. In the MBE system, rotate the substrate heater (CAR) to the beam current position and set it to T stably 0 value. Each time the following steps are performed, this value must be maintained at a certain value, so as to keep the influence of the vacuum chamber environment on the beam current consistent when measuring the beam current.

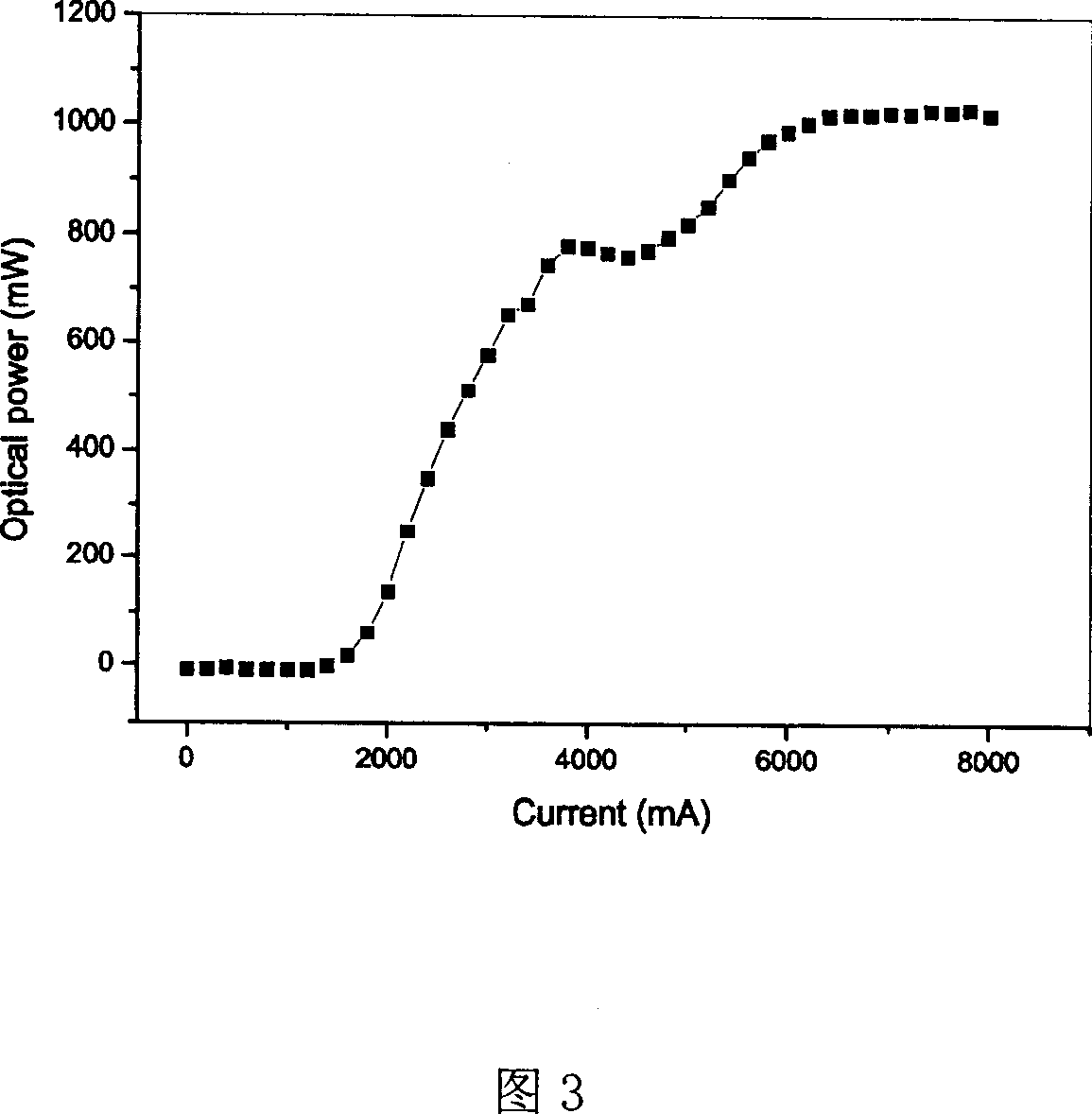

[0027] 2. Raise the temperature of the cracking zone of the source furnace to 1150°C. During this process, gradually increase the valve value of the cracking valve until it is V 1 =295mil, and when the cracking zone temperature T c After the temperature is higher than 700°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com