Fex@Co<1-x>P-RGO composite material as well as in-situ synthesis method and application thereof

A composite material and in-situ synthesis technology, which is applied in the field of hydrogen energy, can solve problems such as poor catalytic activity and stability, low specific surface area of the carrier, and dangerous preparation methods, and achieve fast speed, high reactivity, and improved hydrogen evolution performance and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a kind of Fe x @Co 1-x P-RGO composite material, its preparation method is as follows:

[0044] 1) Mix 2mmol iron acetate, 2mmol cobalt acetate and 20ml 3g / L graphene oxide solution and ultrasonically disperse for 30min to completely dissolve the solid to obtain a solution, then add 8mmol phytic acid to the solution and ultrasonically stir and disperse at 50°C for 8h , to obtain the reaction solution;

[0045]2) Move the reaction solution into a hydrothermal autoclave and heat it under high temperature at 180°C for 12 hours, centrifuge the product solution after the hydrothermal reaction, collect the precipitate, and place the precipitate in a vacuum drying oven to dry at 60°C Dry for 16 hours to obtain the precursor;

[0046] 3) Put the precursor into a resistance furnace, pass through nitrogen, and calcinate at a high temperature of 800°C for 2 hours to obtain Fe x @Co 1- x P-RGO composites.

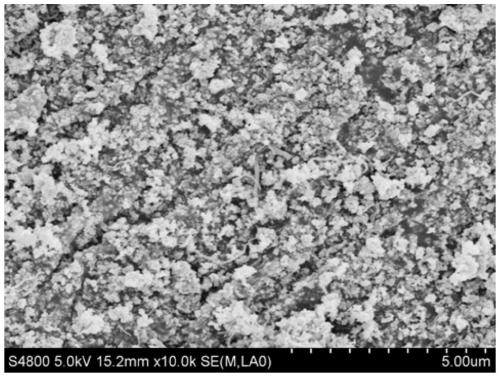

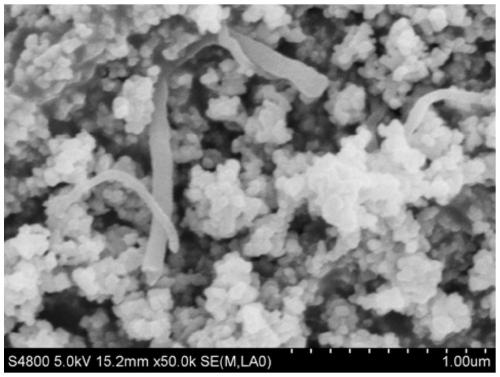

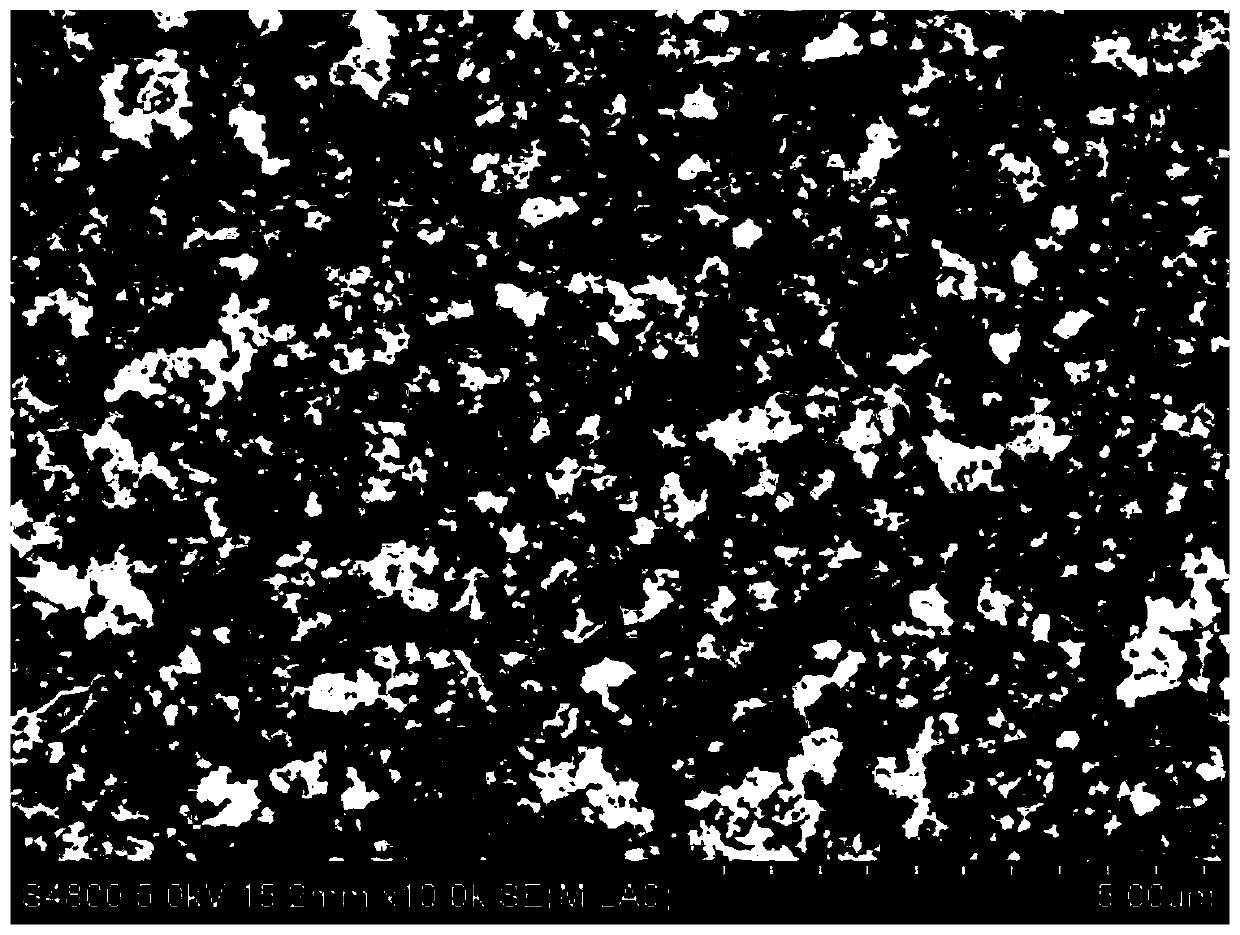

[0047] Prepared Fe x @Co 1-x The scanning electron microscope imag...

Embodiment 2

[0049] In this embodiment, the Fe prepared in Example 1 x @Co 1-x The electrocatalytic hydrogen evolution reaction of the P-RGO composite material includes the following steps:

[0050] 1) Fe prepared in Example 1 x @Co 1-x Grind the P-RGO composite material, and grind the surface of the glassy carbon electrode with 0.05 μm alumina to remove the residual sample, and rinse the glassy carbon electrode with ethanol and water in turn, and dry it;

[0051] 2) Prepare 1.0M potassium hydroxide solution, and feed nitrogen into the potassium hydroxide solution for 30 minutes to remove the air in the electrolyte, and obtain the electrolyte;

[0052] 3) Prepare 0.5wt% Nafion solution with anhydrous methanol, weigh 1mg Fe x @Co 1-x The P-RGO composite material was dissolved in 100 μL Nafion solution and ultrasonically dispersed for two hours to obtain a hydrogen evolution solution, and then absorbed 12 μL hydrogen evolution solution and drip-coated on the glassy carbon electrode, and...

Embodiment 3

[0056] a kind of Fe x @Co 1-x P-RGO composite material, its preparation method is as follows:

[0057] 1) Mix 0.25mmol iron acetate, 1.75mmol cobalt acetate and 30ml 3g / L graphene oxide solution and ultrasonically disperse for 20min to completely dissolve the solid to obtain a solution, then add 16mmol phytic acid to the solution and ultrasonically stir at 50°C Disperse for 8 hours to obtain a reaction solution;

[0058] 2) Move the reaction solution to a hydrothermal autoclave and heat it under high temperature at 120°C for 18 hours, centrifuge the product solution after the hydrothermal reaction, collect the precipitate, and dry the precipitate in a vacuum drying oven at 60°C Dry for 12 hours to obtain the precursor;

[0059] 3) Put the precursor into a resistance furnace, pass through nitrogen, and calcinate at a high temperature of 500 ° C for 2 hours to obtain Fe x @Co 1- x P-RGO composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com