Water heat systhesis method for preparing phosphide nanometre wire

A technology of hydrothermal synthesis and nanowires, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of uneven product particle size, high cost of raw materials and equipment, etc., and achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a Teflon-lined autoclave, add 12 mmol NaOH and 1.5 mmol Ga 2 o 3 or In 2 o 3 , then add 30mL of water; after the solid is completely dissolved, add 3mmol cetyltrimethylammonium bromide (C 16 h 33 (CH 3 ) 3 NBr), 3mL n-hexanol, 10mL heptane; after stirring for 20 minutes, add 1g white phosphorus, 0.75g elemental iodine (I 2 ), sealed the autoclave, and kept the temperature at 160°C for 24 hours; the resulting product was washed twice with benzene, alcohol, dilute hydrochloric acid (1mol / L), and water successively, placed in a vacuum drying oven, and dried at 60°C for 4 hours. That is the product powder.

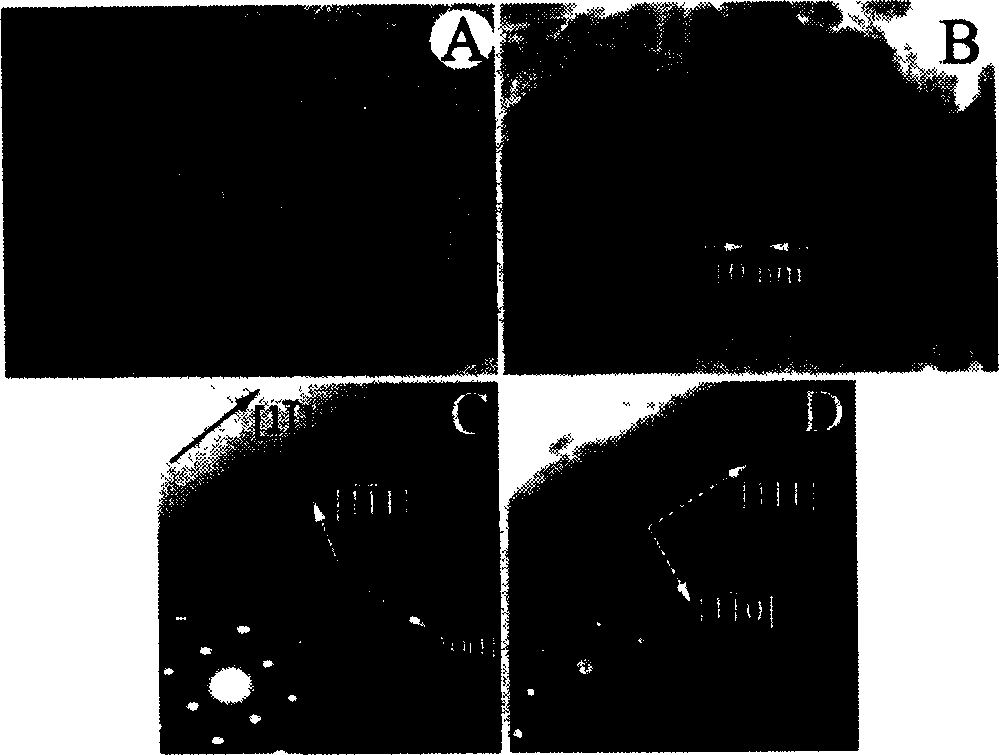

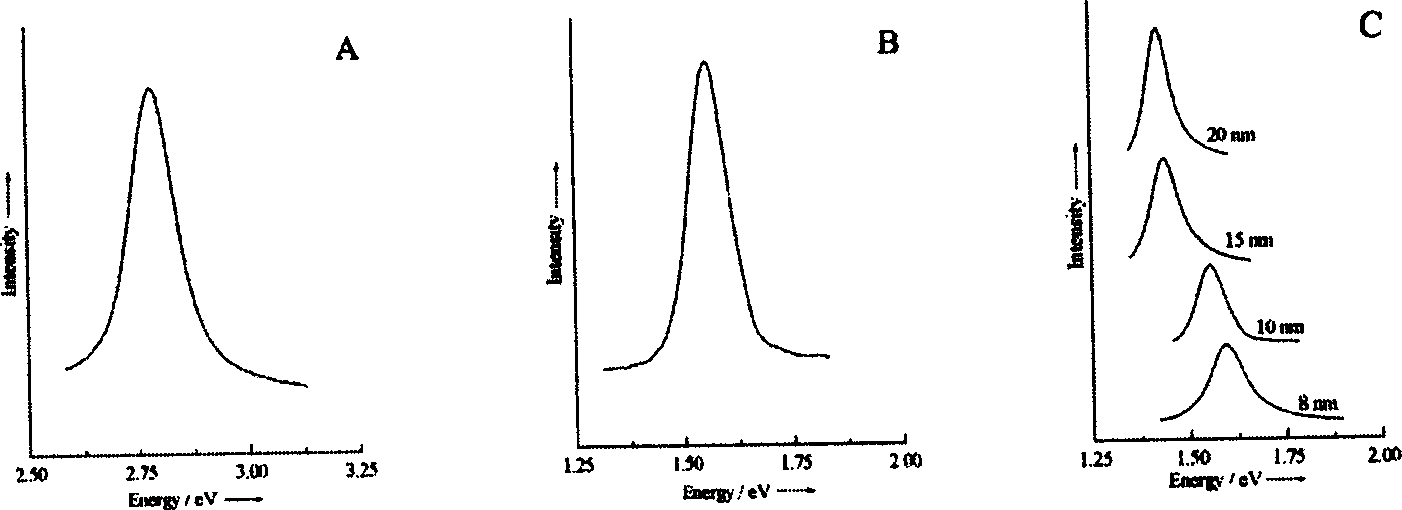

[0020] Adopt target X-ray powder diffraction (XRD), field emission scanning electron microscope (FE-SEM), high resolution transmission electron microscope (HRTEM), electron diffraction (ED) and photoluminescence spectrum (PL) to obtain in the above-mentioned embodiment The product is characterized.

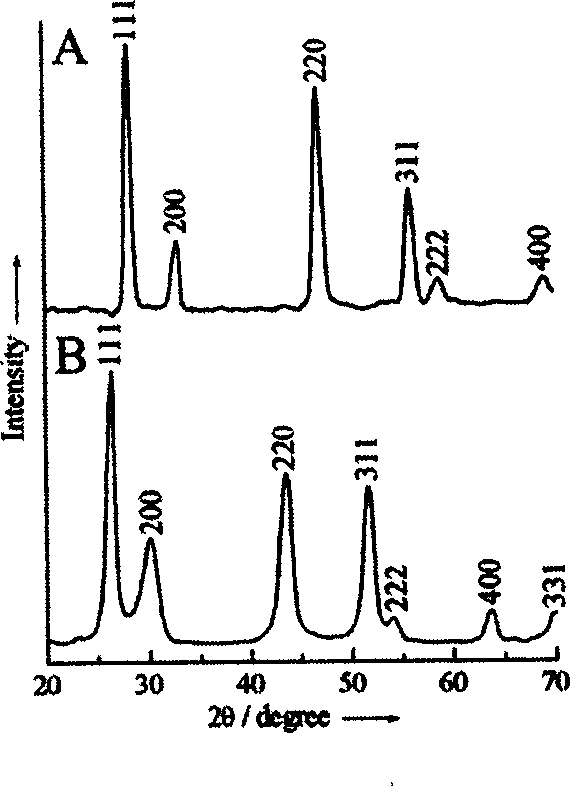

[0021] figure 1 The given product powder XRD patterns A a...

Embodiment 2

[0026] In a Teflon-lined autoclave, add 12 mmol NaOH and 1.5 mmol In 2 o 3 , then add 30mL of water; after the solid is completely dissolved, add 6mmol cetyltrimethylammonium bromide (C 16 h 33 (CH 3 ) 3 NBr), 3mL n-hexanol, 10mL heptane; after stirring for 20 minutes, add 0.5g white phosphorus, 0.37g elemental iodine (I 2), sealed the autoclave, and kept the temperature at 160°C for 24 hours; the resulting product was washed twice with benzene, ethanol, dilute hydrochloric acid (1mol / L), and water successively, placed in a vacuum drying oven, and dried at 60°C for 4 hours. That is the product powder.

[0027] The products obtained in the above examples were characterized by using target X-ray powder diffraction (XRD), transmission electron microscopy (TEM) and photoluminescence spectroscopy (PL).

[0028] Product powder XRD patterns and figure 1 B is consistent, indicating that the product is InP of sphalerite phase;

[0029] TEM photo Figure 4 A shows that the InP ...

Embodiment 3

[0032] In a Teflon-lined autoclave, add 12 mmol NaOH and 1.5 mmol In 2 o 3 , then add 30mL of water; after the solid is completely dissolved, add 3mmol cetyltrimethylammonium bromide (C 16 h 33 (CH 3 ) 3 NBr), 3mL n-hexanol, 10mL heptane; after stirring for 20 minutes, add 1g white phosphorus, 0.75g elemental iodine (I 2 ), sealed the autoclave, and kept the temperature at 160°C for 48 hours; the resulting product was washed twice with benzene, alcohol, dilute hydrochloric acid (1mol / L), and water successively, placed in a vacuum drying oven, and dried at 60°C for 4 hours. That is the product powder.

[0033] The products obtained in the above examples were characterized by using target X-ray powder diffraction (XRD), field emission scanning electron microscopy (FE-SEM) and photoluminescence spectroscopy (PL).

[0034] Product powder XRD pattern and figure 1 B is consistent, indicating that the product is InP of sphalerite phase;

[0035] FE-SEM photo Figure 4 B show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com