High-contrast organic luminous display

A light-emitting display, high-contrast technology, applied in the direction of electroluminescent light source, light source, electric light source, etc., can solve the problems of affecting the stability and efficiency of light-emitting elements, high cost, and increasing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

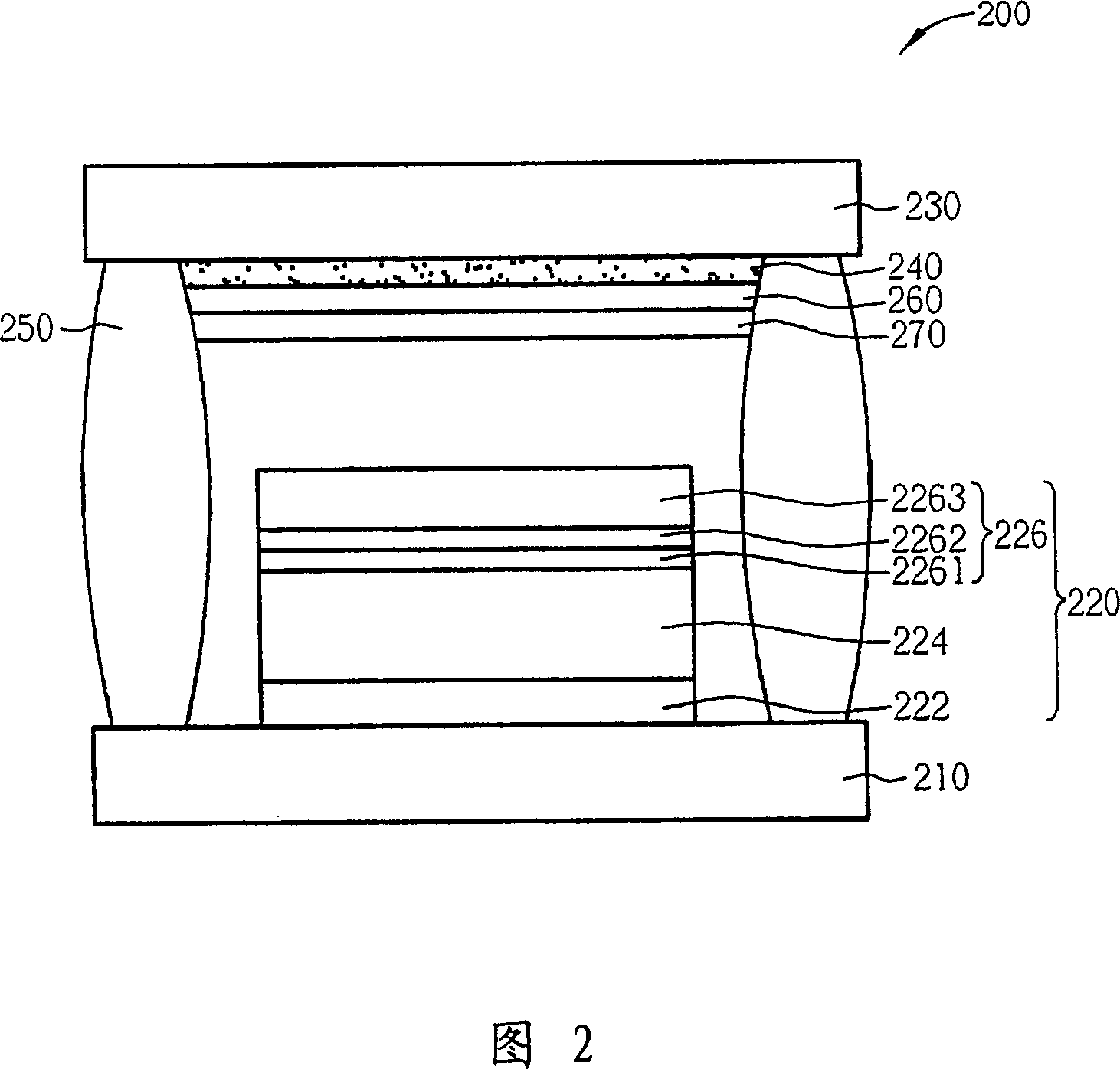

[0029] Please refer to FIG. 2 . FIG. 2 is a schematic diagram of a high-contrast organic light-emitting display according to a first preferred embodiment of the present invention. According to the first preferred embodiment of the present invention, the high-contrast organic light-emitting display 200 includes a transparent substrate 210, such as a glass substrate, a quartz substrate or a polyacrylate (polyacrylates) substrate, a polymethacrylate (polymethacrylates) substrate, etc. to carry the light emitting structure 220 . The light emitting structure 220 includes a transparent lower electrode 222 , an organic layer 224 and an upper electrode structure 226 . Wherein, the material of the transparent bottom electrode 222 can be selected from materials such as Indium Tin Oxide (ITO), Indium Zinc Oxide (IZO), etc., as the anode electrode for inputting holes. In this embodiment, the organic layer 224 is the light-emitting layer, which can be made of polyphenylenevinylenes, polyf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com