Waste heat recovery apparatus, waste heat recovery system, and method of recovering waste heat

A technology of waste heat recovery and sensible heat recovery, applied in charging systems, gas turbine devices, chemical instruments and methods, etc., can solve the problems of not being able to become and not getting fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

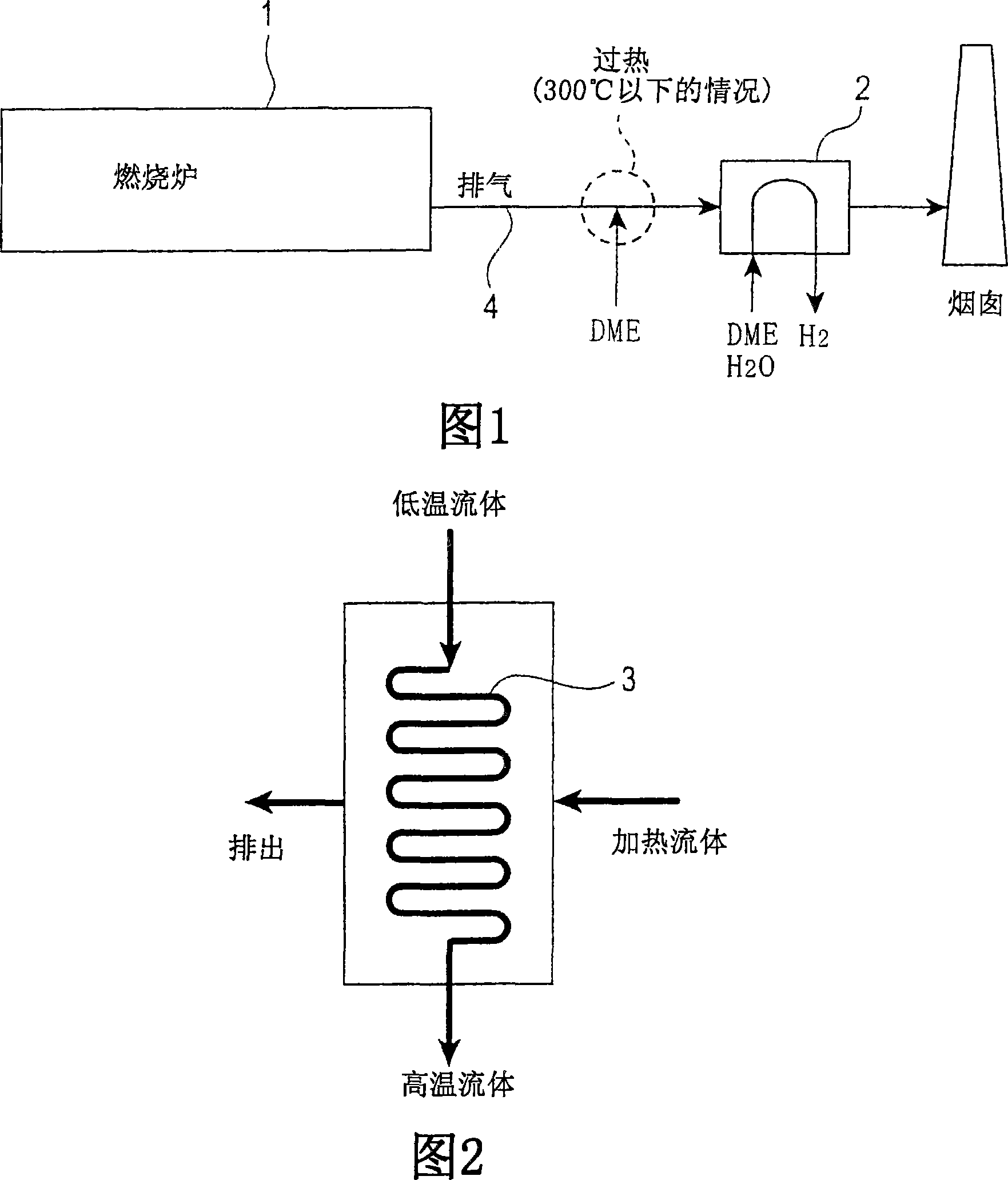

[0055] Embodiments of the present invention will be described below. FIG. 1 shows a waste heat recovery device according to a first embodiment of the present invention. A heat exchanger 2 is provided on the exhaust system 4 of the combustion furnace 1, and dimethyl ether (hereinafter referred to as DME) and water vapor (hereinafter referred to as H 2 O) The mixed gas passes through the heat exchanger 2. Through the heat exchange between the exhaust gas and DME in the heat exchanger 2, the DME is thermally decomposed into H 2 , recovering the sensible heat of the exhaust gas as H 2 fuel.

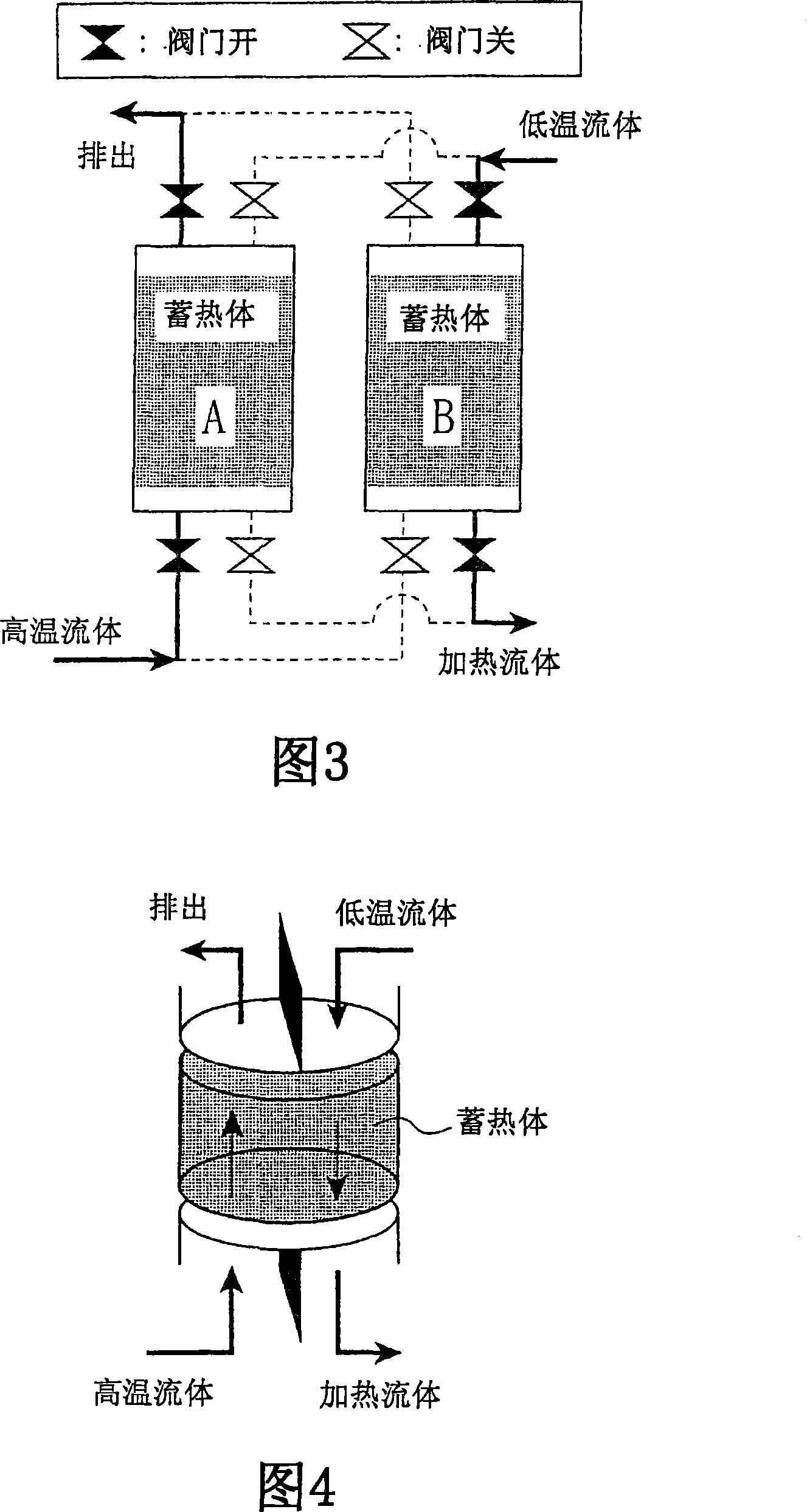

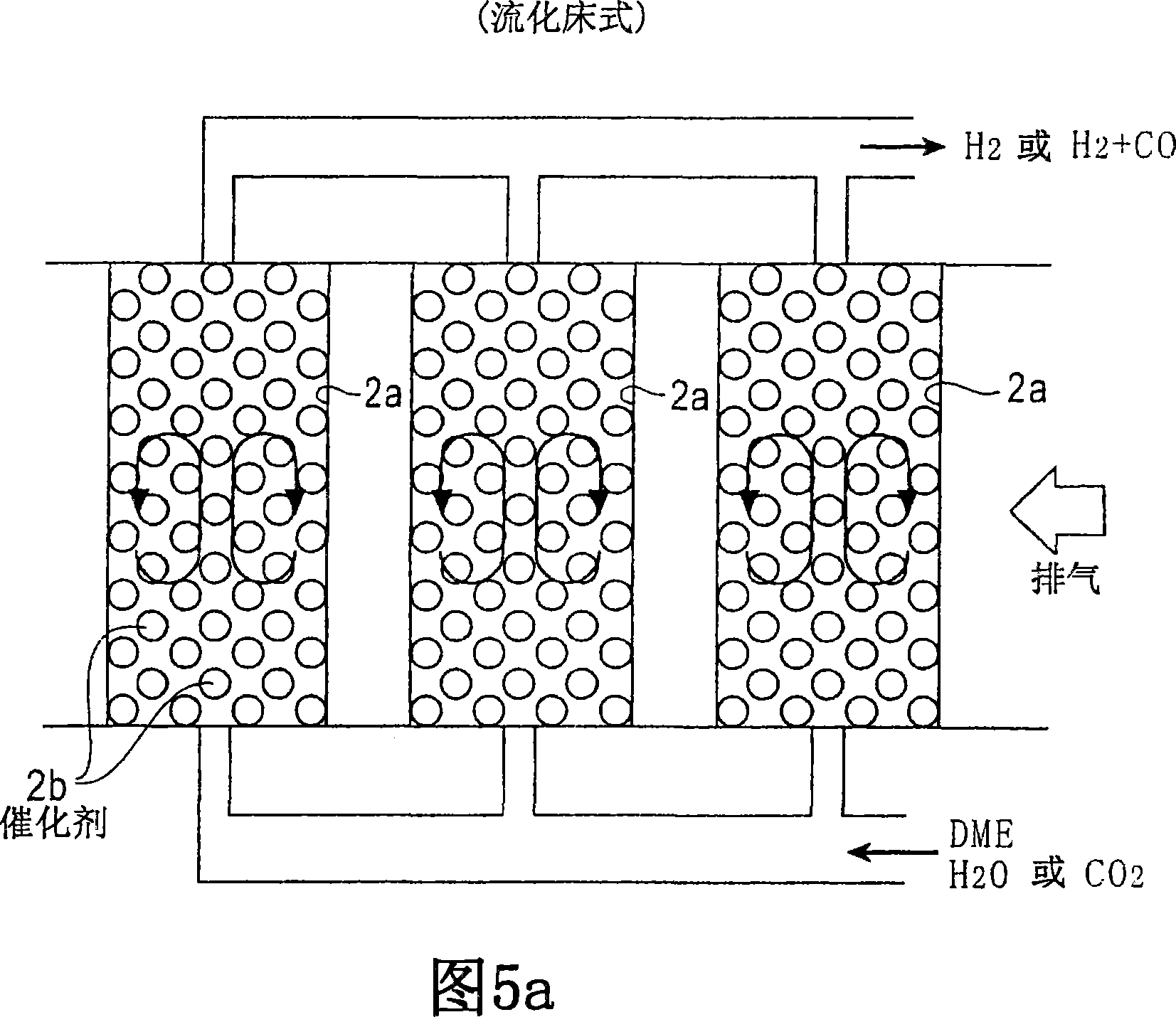

[0056] As the heat exchanger 2, various structures such as a tube type, a plate type, an enlarged heat transfer surface, a heat storage type, a fluidized bed type, and a heat medium circulation type can be used. Figure 2 shows an example of a tubular heat exchanger (recovery heat exchanger called a recuperator), Figures 3 and 4 show a heat storage heat exchanger, and Figure 5 shows a flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com