Magnet roller

A technology of magnetic rollers and magnetic blocks, applied in the directions of magnets, magnetic objects, magnetic materials, etc., can solve the problems of high cost, difficulty in forming magnetic flux density patterns, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

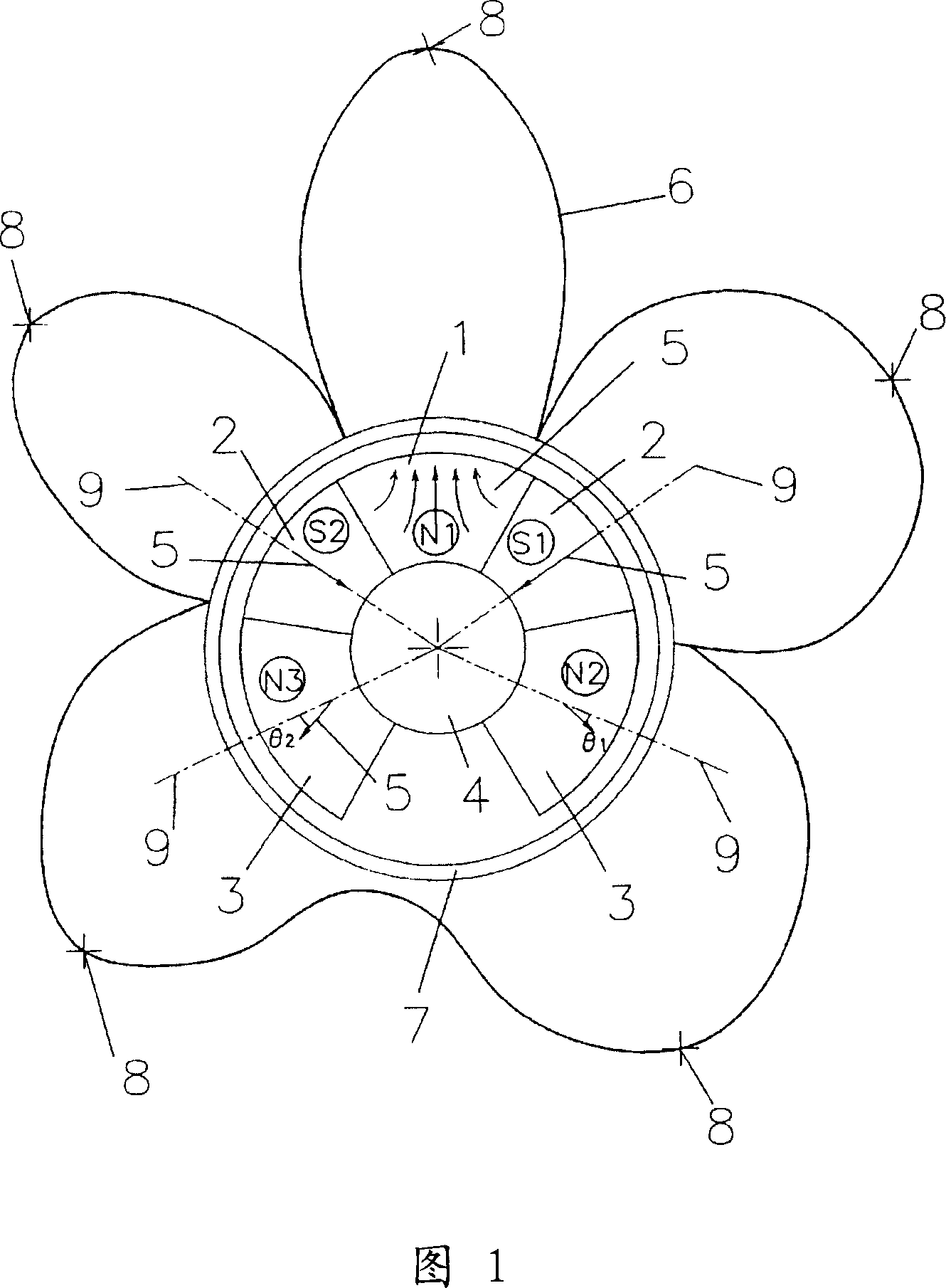

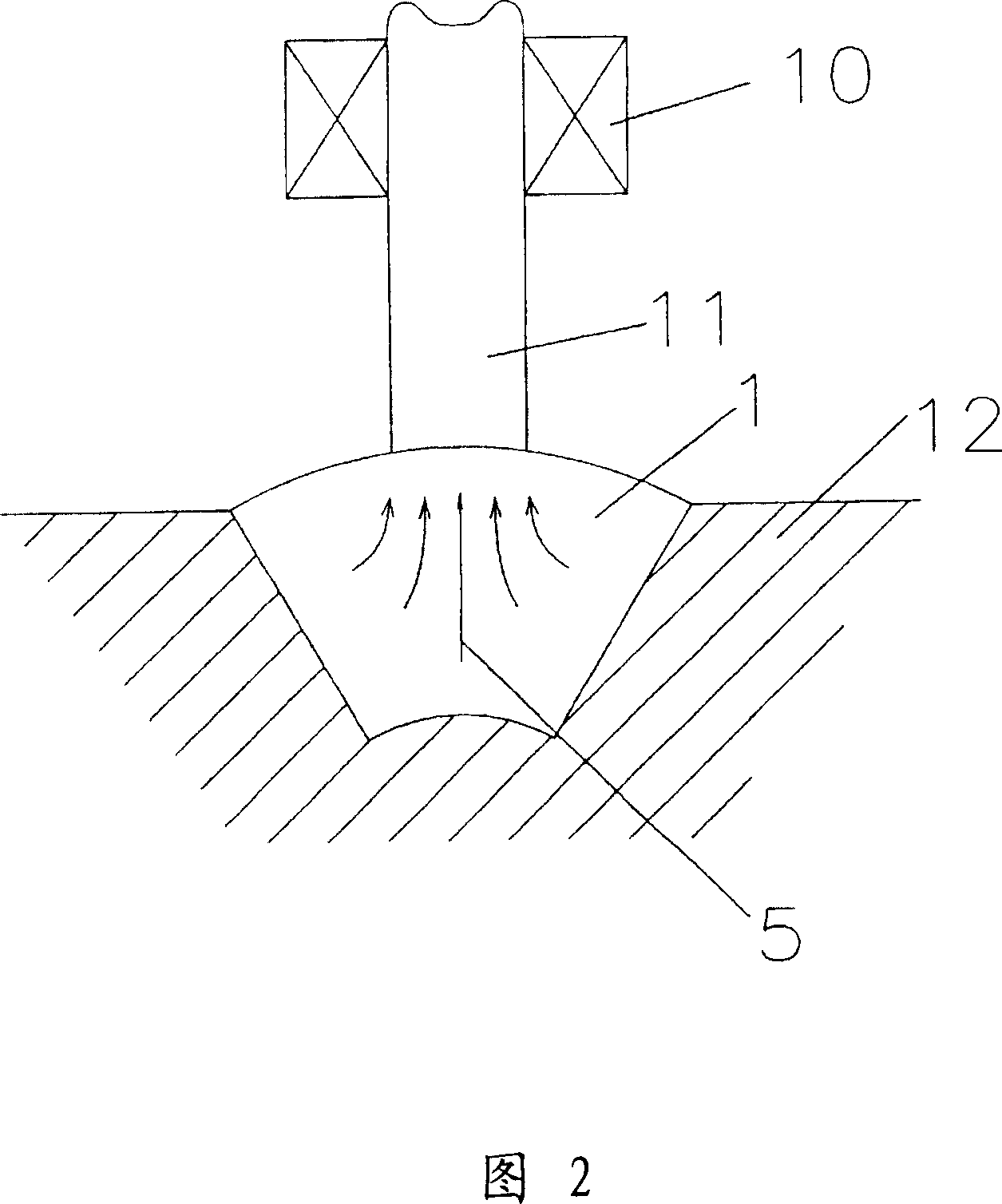

[0075] As the magnetic block material for the N1 pole in Fig. 1, 10% by weight (including lubricant, plasticizer, and stabilizer) of nylon 6 (Ube Industries, Ltd. P1010) was used as the resin binder, and 90% by weight was used as the magnetic powder. % anisotropic strontium ferrite magnetic powder (SrO·6Fe 2 o 3 ), mix them and melt and stir them to form granules, and make the granules into a molten state, use the mold shown in Figure 2 to inject the molten resin magnet material from the injection port, and apply a magnetic field of 1200K·A / m to make the molten resin magnet The polarity of the magnetic particles is anisotropically oriented and magnetized, and the N1 pole of the magnetic block shown in FIG. 1 is injection molded.

[0076] In addition, as a magnetic block material for poles other than the N1 pole (S1 pole, N2 pole, N3 pole, S2 pole) in Figure 1, the resin binder uses 10% by weight (including lubricants, plasticizers, stabilizers) chlorine Polyethylene (Ebaslen...

Embodiment 2

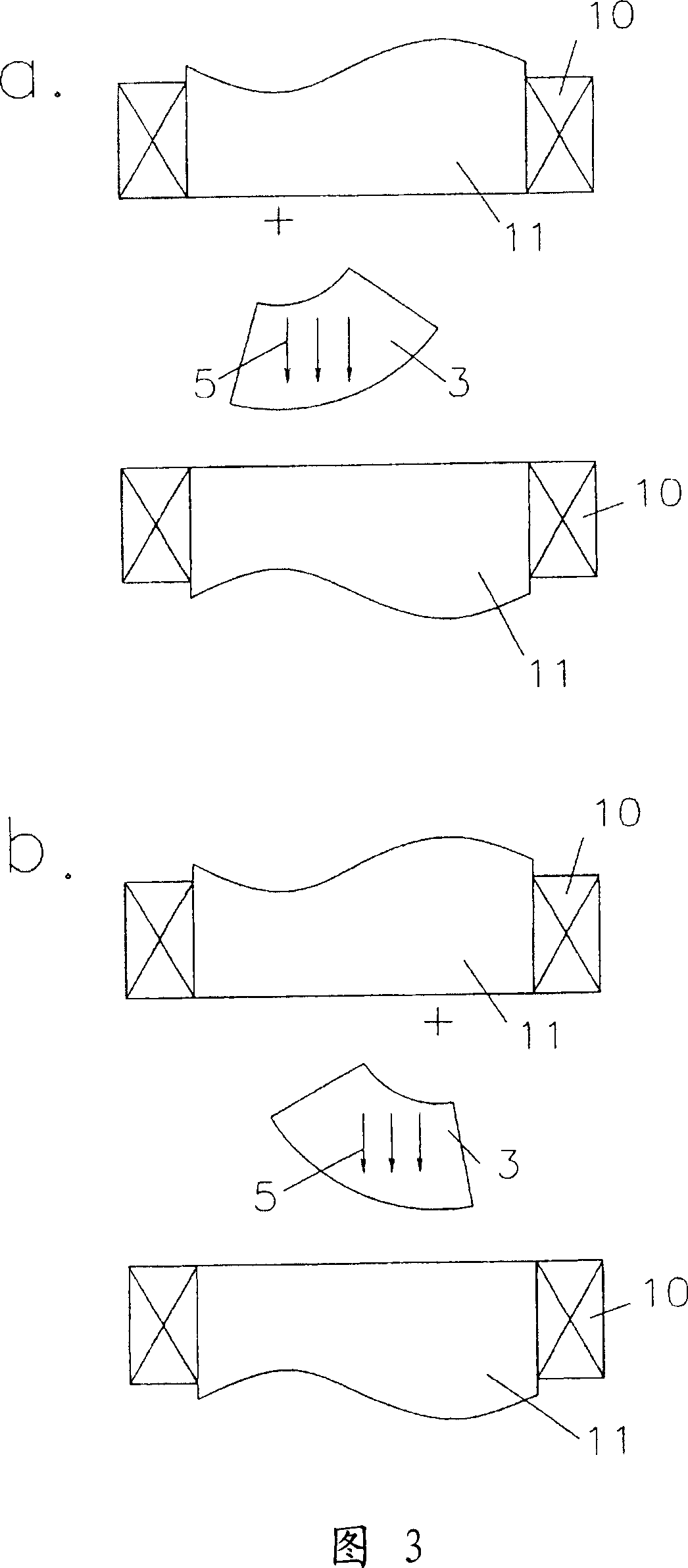

[0084]As the magnet material for extrusion molding (S1 pole, N2 pole, N3 pole, S2 pole), the resin binder adopts 10% by weight (including lubricant, plasticizer, stabilizer) of ethylene ethyl acrylate (Japanese Yuerka No.1 PES-210), as the magnetic powder adopts 90% by weight anisotropic strontium ferrite magnetic powder (SrO·6Fe 2 o 3 ), they are mixed and melted and stirred to form granules, and the granules are in a molten state, using the dies (extrusion dies) of a, b in Figure 3 and a, b in Figure 4, while applying 240K·A / m~ A magnetic field of 2400K·A / m was used to orient and magnetize the magnetic particles of the molten resin magnet in one direction for each piece, and extrusion molding was carried out. The same procedure as in Example 1 was carried out.

[0085] Tables 1 to 4 show the measurement results.

Embodiment 3

[0087] As the magnet material for injection molding (N1 pole), nylon 12 (Ube Industries Co., Ltd. P3012U) with 10% by weight (including lubricant, plasticizer, and stabilizer) is used as the resin binder, and 90% by weight is used as the magnetic powder. % anisotropic strontium ferrite magnetic powder (SrO·6Fe 2 o 3 ), except that, the same steps as in Example 1 were carried out.

[0088] Tables 1 to 4 show the measurement results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com