Target and process kit components for sputtering chamber

A sputtering target and sputtering chamber technology, applied in metal material coating process, sputtering plating, electrical components, etc., can solve the problems of increased process cost, thermal stress peeling, contamination of the substrate, etc., and can prolong the start-up time. effect of time, uniform deposition, increased throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

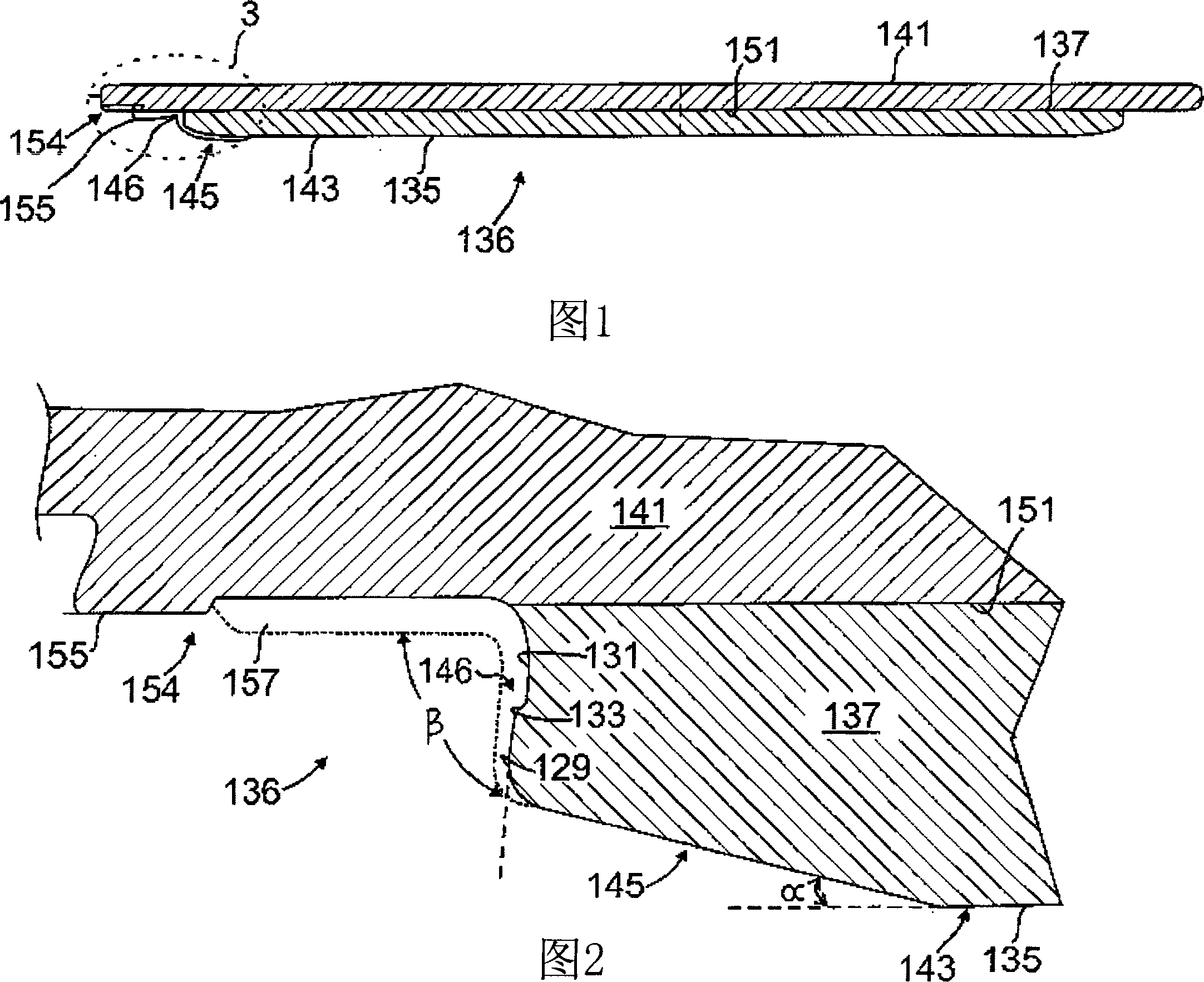

[0038] 1 and 2 illustrate an exemplary embodiment of a sputter target 136 that may be used in a sputter processing chamber to deposit sputtered material on a substrate. As shown in the exemplary chamber embodiment of FIG. 9 , during processing in chamber 100 , sputtering surface 135 of sputtering plate 137 of target 136 is positioned opposite substrate 104 . In one aspect, the sputtering plate 137 includes a central cylindrical mesa 143 with a sputtering surface 135 forming a plane parallel to the plane of the substrate 104 . The annular sloped side 145 surrounds the columnar mesa 143 . In one aspect, the annular edge 145 is inclined at an angle α of at least about 8°, eg, from about 10° to about 20°, eg, 15°, relative to the plane of the cylindrical mesa 143 . A peripheral sloping side wall 146 with a step 133 surrounds the annular edge 145 . The peripheral sloped sidewall 146 is sloped at an angle β of at least about 60° relative to the plane of the cylindrical mesa 143 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com