Low pressure leaching process of coal-bearing kaolin powder for producing industrial alumination sulfate

An industrial sulfuric acid and coal-based technology, applied in the direction of aluminum sulfate, aluminum sulfur compounds, etc., can solve problems such as poor mixing of coal gangue raw powder and sulfuric acid solution, lack of corresponding measures for anti-corrosion technology, and difficulty in ensuring product quality. Advanced type selection and anti-corrosion technology, stable and reliable product quality, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The best embodiment of the present invention is provided below

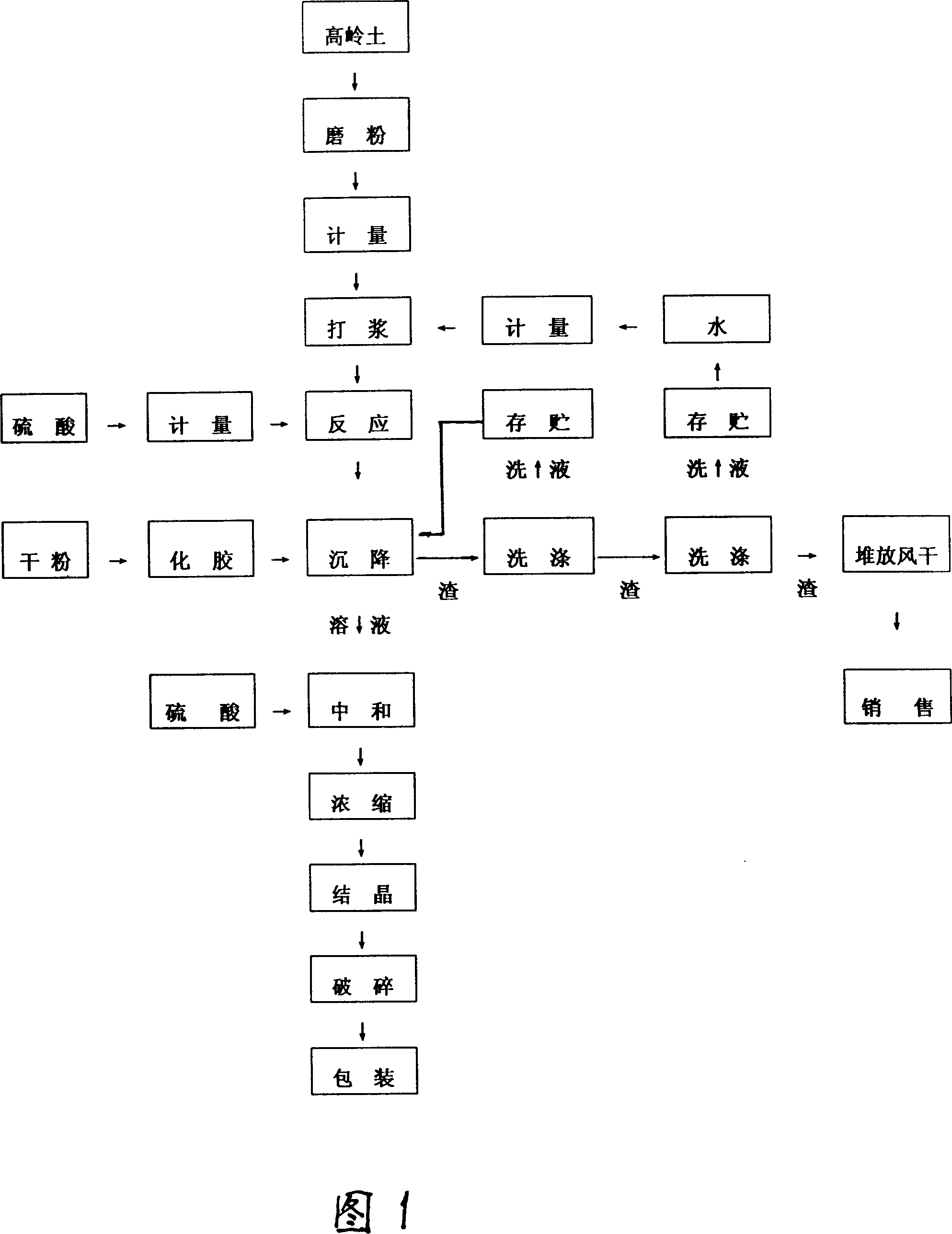

[0021] Raw ore that will meet the quality requirements (AI 2 o 3 Content ≥ 34%, Fe 2 o 3 content ≤ 2.0%) sent to the jaw crusher for crushing to a lump size ≤ 2.0cm, then milled by a Raymond machine (4R3216 mill) with a fineness of 150-200 mesh. Method feeding into the silo. When mixing slurry, the mineral material is measured by the electromagnetic hanging bucket, and the water is measured by the liquid level gauge. After the weight ratio of the two is prepared in the mixing tank to a concentration of 55-65%, the air compressor is turned on and sent to the KPI cement lining for lead lining. Inside the reactor of graphite bricks.

[0022] Mix the ore pulp in the reaction kettle with a certain amount of sulfuric acid, add 610kg of sulfuric acid for every 0.55kg of ore pulp (the quality of sulfuric acid should meet the requirements of international industrial first-class products), and preheat it with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com