Flotation technology of complicated refractory sulfide ore accompanying silicon/aluminum

A technology for refractory and sulfide ores, applied in flotation, chemical instruments and methods, solid separation, etc., can solve problems such as difficulty in flotation separation, deterioration of flotation environment, and high difficulty, and achieve obvious economic and social benefits and technological Reliable, technologically advanced results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

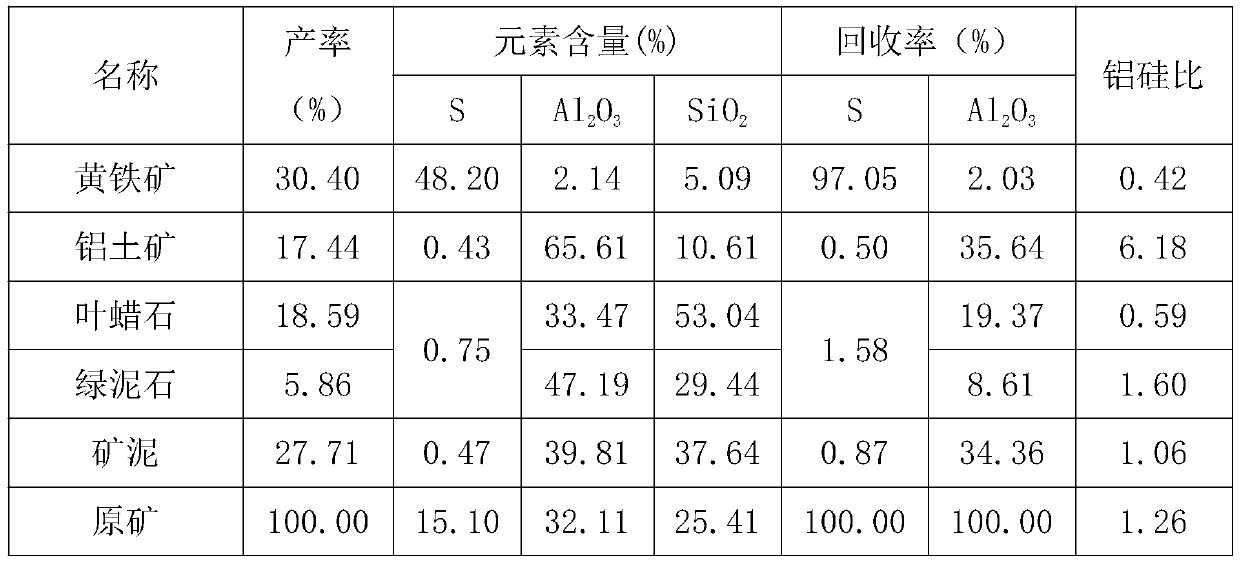

[0037] 1. Ore characteristics

[0038] The complex and refractory sulfide ore associated with silicon / aluminum resources in a certain place, the chemical content of the four main components of sulfur, iron, aluminum, and silicon in the ore is as high as 84%, and its S grade is 15.1%, Al 2 o 3 Content 32.1%, SiO 2 Content 25.4%. The main minerals in the ore are: pyrite, diaspore (and a small amount of gibbsite), pyrophyllite, chlorite, kaolinite (containing a small amount of halloysite), anatase, etc.; Few / trace minerals include montmorillonite, sepiolite, mica, gypsum, carbonaceous (graphite), limonite, jarosite, quartz, etc. There are many types of minerals, fine and complex embedded particle size, and the overall resource utilization is extremely difficult.

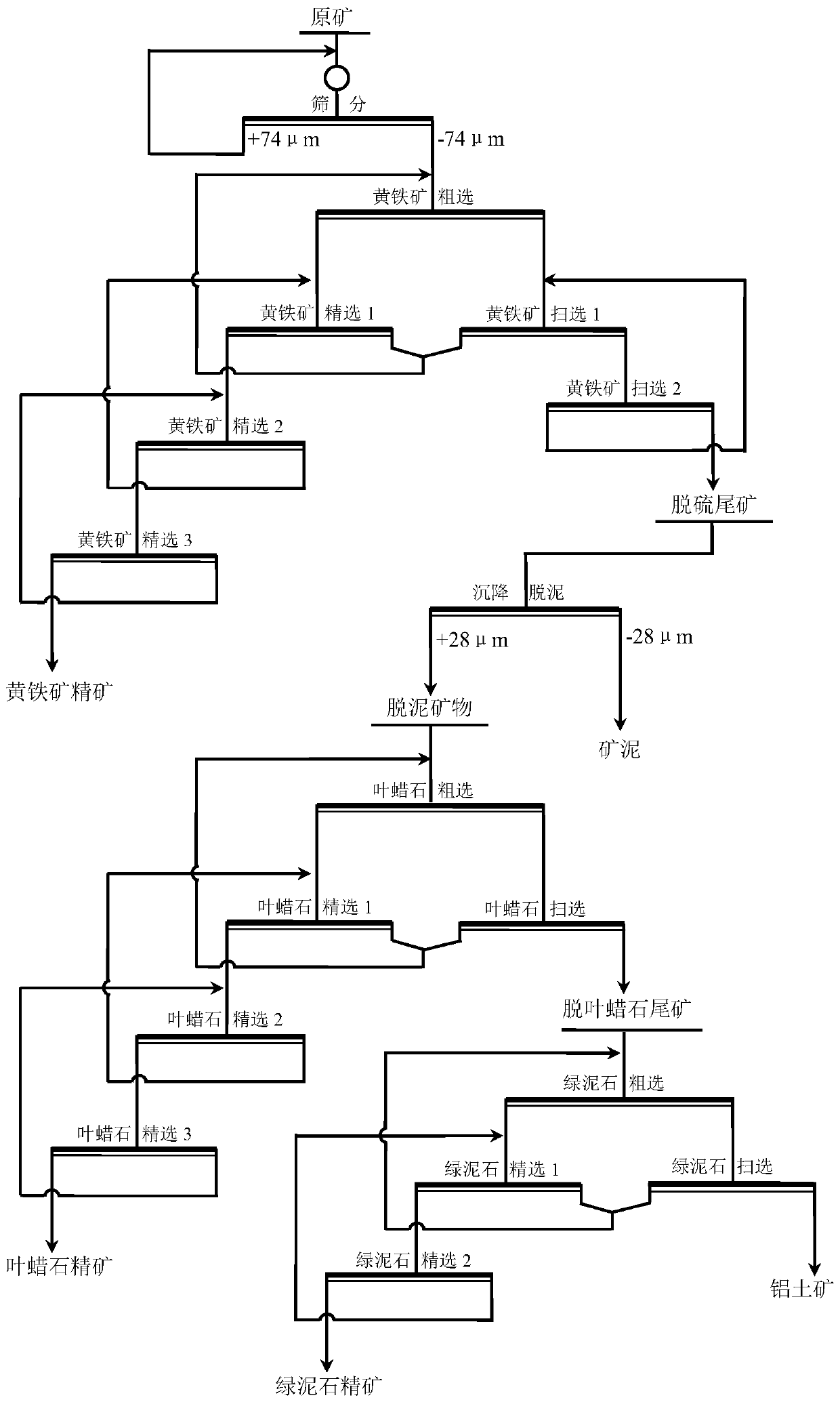

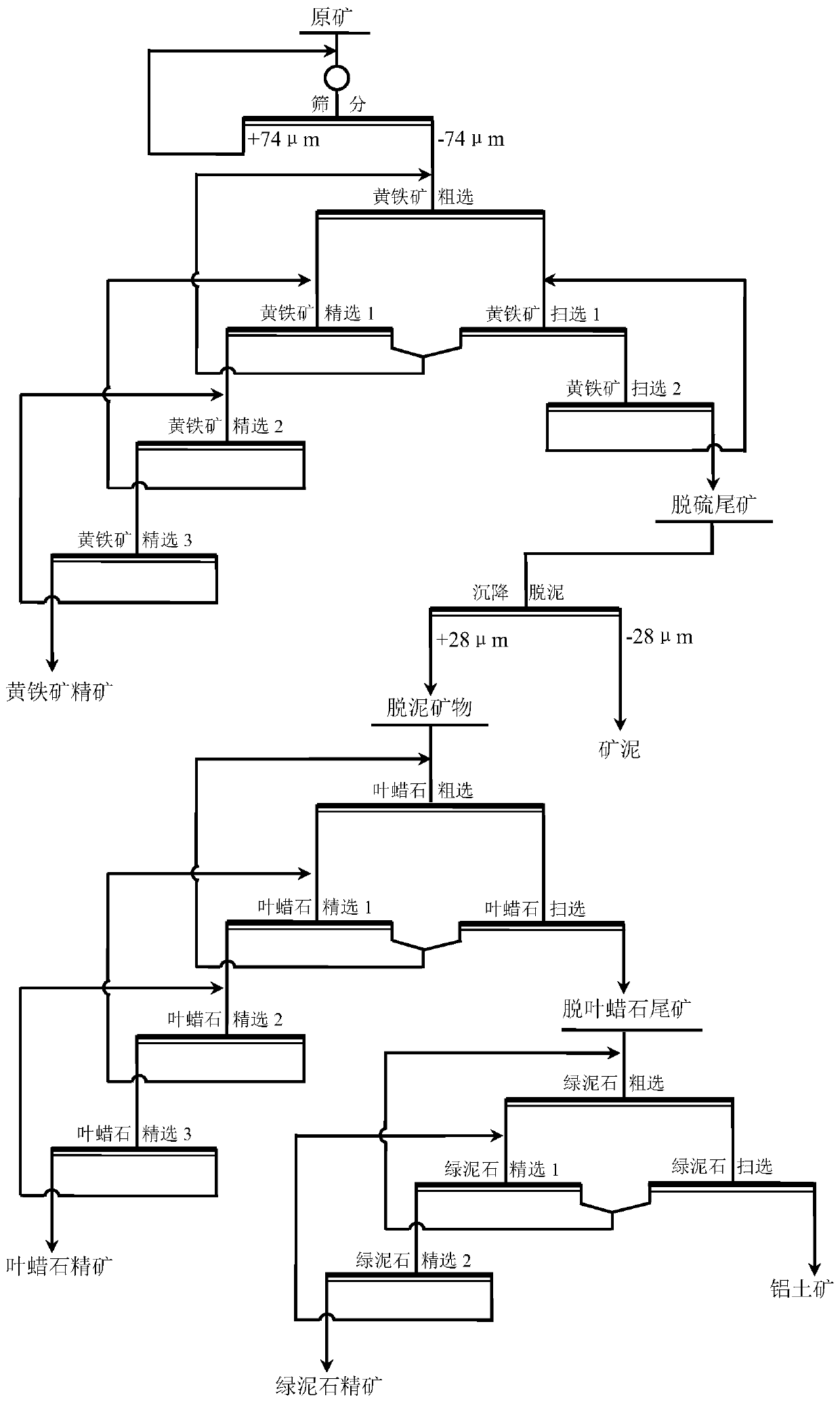

[0039] 2. Mineral dressing process

[0040] (1) Grind the refractory sulfide ore raw ore, and then perform wet screening on the ground product to separate -74μm and +74μm particle size parts, of which the +74μm siz...

Embodiment 2

[0054] 1. Ore characteristics

[0055] A complex and refractory sulfide ore associated with silicon / aluminum resources, the ore is mainly composed of pyrite, pyrophyllite, diaspore and a small amount of kaolinite, montmorillonite, chlorite, anatase and other minerals; the ore The middle S grade is 16.4%. Sulfur exists in the form of pyrite minerals. The technical mineralogical particle size of pyrite is between 0.001mm and 1.32mm, generally between 0.01mm and 0.15mm; the industrial aluminum minerals in the ore are mainly monohydrate Draumeite, pyrophyllite, kaolinite, montmorillonite and other minerals are mixed with each other, and the particle size is fine, so it is difficult to sort.

[0056] 2. Mineral dressing process

[0057] (1) Grind the refractory sulfide ore raw ore, and then perform wet screening on the ground product to separate -74μm and +74μm particle size parts, of which the +74μm size part is returned to the upper level of grinding operation Re-grinding; the ...

Embodiment 3

[0071] 1. Ore characteristics

[0072]The complex and refractory sulfide ore associated with silicon / aluminum resources in a certain place, the chemical content of the four main components of sulfur, iron, aluminum, and silicon in the ore is as high as 84%, and its S grade is 15.1%, Al 2 o 3 Content 32.1%, SiO 2 Content 25.4%. The main minerals in the ore are: pyrite, diaspore (and a small amount of gibbsite), pyrophyllite, chlorite, kaolinite (containing a small amount of halloysite), anatase, etc.; Few / trace minerals include montmorillonite, sepiolite, mica, gypsum, carbonaceous (graphite), limonite, jarosite, quartz, etc. There are many types of minerals, fine and complex embedded particle size, and the overall resource utilization is extremely difficult.

[0073] 2. Mineral dressing process

[0074] (1) Grind the refractory sulfide ore raw ore, and then perform wet screening on the ground product to separate -74μm and +74μm particle size parts, of which the +74μm size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com