Semi silicon sulfide rubber coating textile

A technology for coating fabrics and silicone rubber, applied in coating, textiles and papermaking, etc., can solve the problems of incapability of secondary vulcanization molding, limited scope of use, and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare 140 kg of semi-vulcanized rubber solution.

[0022] 1) Choose flame-retardant methyl vinyl silicone rubber (manufacturer: Jiangsu Hongda Chemical New Material Co., Ltd., brand name: HD-8961), weigh 40 kg with ferric oxide (Fe 2 o 3 ) 2 kilograms of color masterbatches are put into the kneader, add 40 kilograms of 200# gasoline and stir, the stirring speed is 30 rpm, and the stirring time is 2 hours;

[0023] 2) Take by weighing 8 kilograms of 200# gasoline, in a high-speed stirrer, slowly add 4 kilograms of Al2O3 while stirring, to obtain Al2O3 suspension;

[0024] 3) Use modified phenol novolak resin (manufacturer: Cytex Corporation, brand: PN759) as the adhesive, weigh 3 kg, select 2,5-dimethyl-2,5-di-tert-butyl peroxide Hexane oxide is a semi-sulfurizing agent, weigh 4 kilograms, and drop into a kneader simultaneously with the aluminum oxide suspension prepared in the above-mentioned operation, stir evenly, and the stirring speed is 30 rpm, and the time is ...

Embodiment 2-3

[0027] See Table 1 for the formula of the semi-vulcanized glue solution, and the preparation method is the same as in Example 1.

[0028] Table 1: Example 2-3 semi-vulcanized glue formula

[0029] Component names and process conditions

Embodiment 4

[0031] Fabrication of semi-vulcanized silicone rubber coated fabrics on one side.

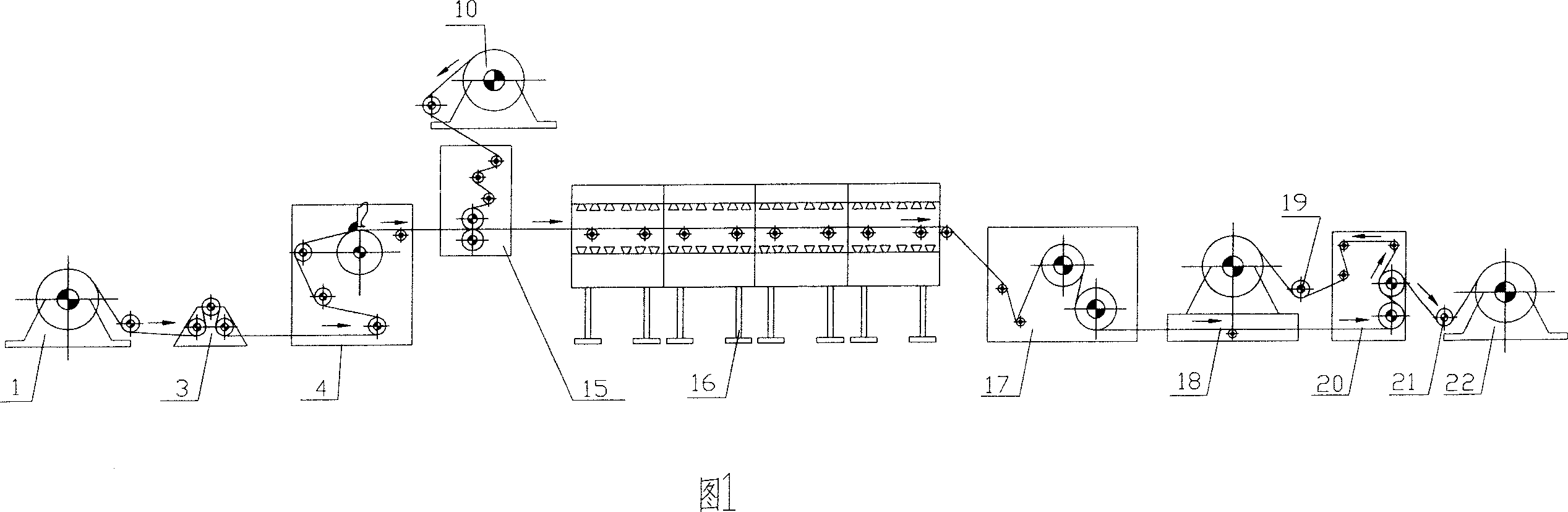

[0032] 1) The substrate treated with the coupling agent is passively unwound from the unwinder 1, and enters the magnetic powder tensioner 3 to adjust the tension, and then the substrate is scraped at the scraping head 4, and the gap between the scraping heads is adjusted to 90 wires; Pass through laminating machine 15 again, finish drying process in baking oven 16, and drying temperature is 70 ℃, and the baking time of control product in baking oven is 4 minutes, finishes cooling in two roller cooling 17, passes separator 20 again Guide, and finally pass through the guide roller 19 on the winder 18 and apply a layer of 3-wire polyethylene isolation film to complete the winding or complete the winding on the winder 22 through the guide roller 21;

[0033] 2) Place the above-mentioned finished coil on the unwinder 1 of the unit again, with the semi-vulcanized rubber facing up, set the polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com