Phyllosilicate slurry for papermaking

A technology of phyllosilicate and slurry, which is applied in the field of papermaking, can solve problems such as water filtration performance and retention performance that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

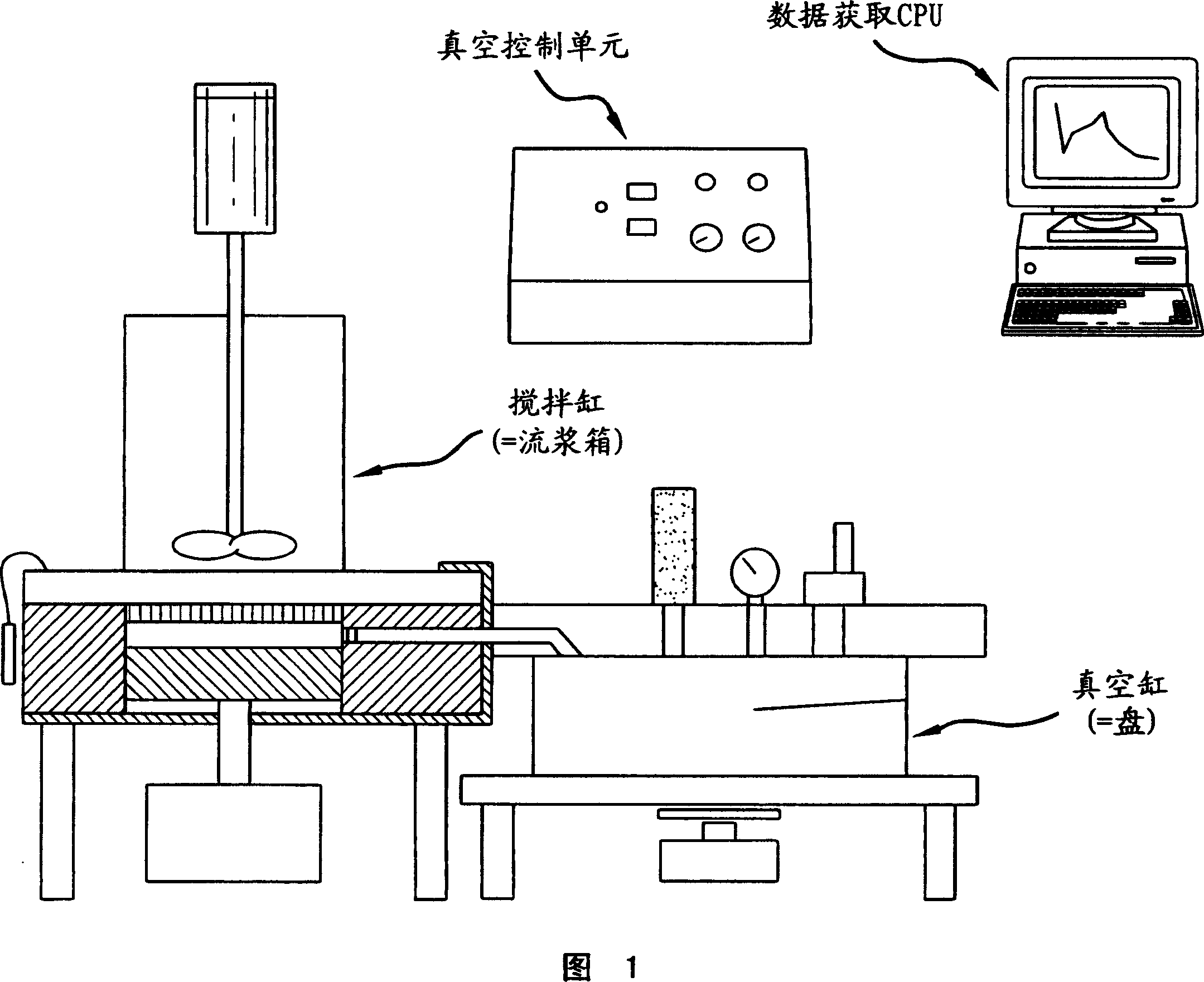

Image

Examples

Embodiment 1

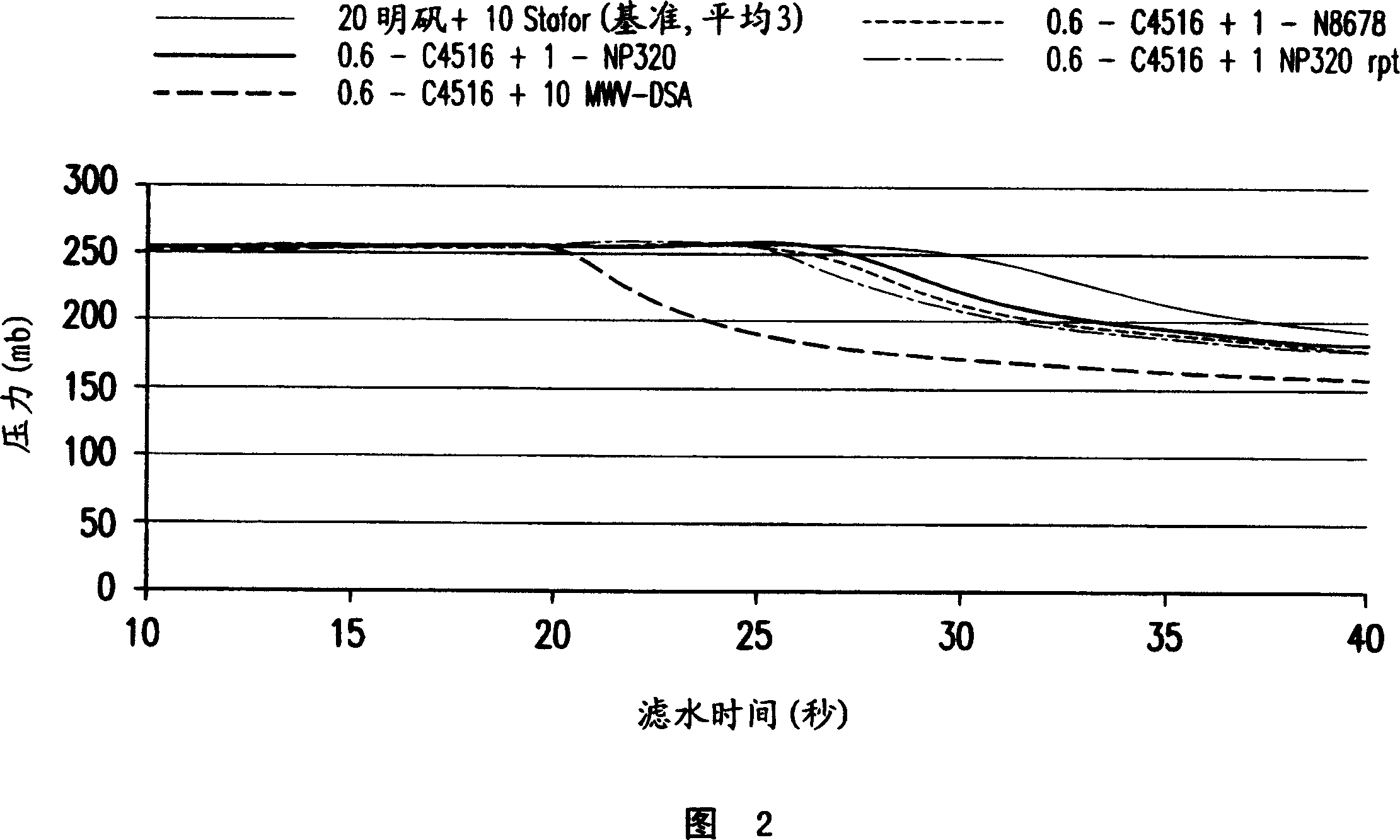

[0038] This example provides a comparison between the drainage rate of a standard fiber stock sample retention process using 10 lb / ton of the drainage and sizing aid of the present invention ("DSA157") and the use of the following aids: (1) Polymer Acrylamide flocculant retention aids such as Nalco 7530 or Cytec 4516; (2) silica filter aids, ie Eka Nobel NP320, and (3) particulates, ie Nalco 8678, lignosulfonate filter aids. The standard fiber stock sample was 20% broke, 70% hardwood and 10% pine at a stock consistency DDA of 1.1-1.2% and a pH of 4.1-4.3. Dilution water from the pan is provided by PM5 (no filter aid residue). The blend chest stock (raw CSF) was 650ml. Except for 10 lb / ton of DSA, all sample runs contained 20 lb / ton of alum slurry and 10 lb / T of size with rosin blended according to the invention in place of separately added sizing Type dispersant.

[0039] The results illustrated in the sample sample of Fig. 2 show that the raw material sample containing the...

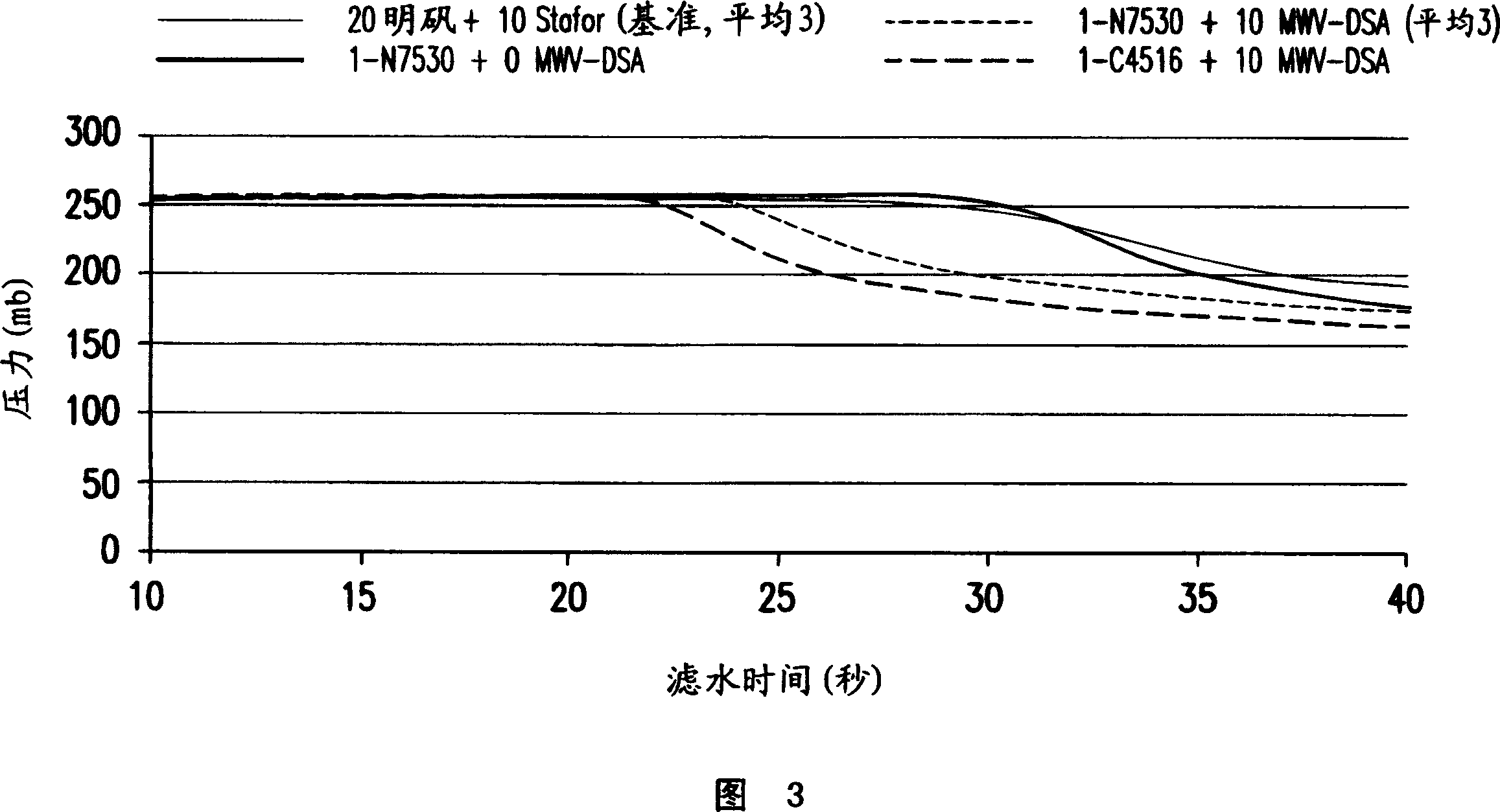

Embodiment 2

[0041] In this example, the constant total amounts of alum and rosin size in the papermaking suspension were 10 lbs / ton size and 20 lbs / ton alum. Adjust the slurry and overall rosin to maintain this level. The slurry contains a different blend of rosin than the rosin size, but the amount of rosin in the suspension is always the same on a total solids basis. In some samples the whole rosin was with the stock in the papermaking suspension, in others it was split and 50% was added with the alum and 50% was provided from the stock. The results are shown in Figures 4-6.

[0042] In Figure 4, the columns are organized by filter aid. For example: "Split DSA 5" means 5 lbs / ton of bentonite in DSA, while the size is fed separately, 5 lbs / ton with DSA and 5 lbs / ton with amygdalin initially. "Nalco 8678 1 Rev" refers to 1 lb / ton N8678 filter aid, but feed in reverse order, filter aid first, flocculant after. "NP320 1" has 1 lb / ton of NP320 silica, "NP320 2" has 2 lb / ton of silica, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com