Aeroplane oil box leakage source checking device

A detection device and aircraft fuel tank technology, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the inconvenient use and adjustment, the difficulty of detecting the exact position of the internal leakage point, and the structure of the fuel tank Seal damage and other problems, to achieve the effect of easy processing and assembly, simple and convenient structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

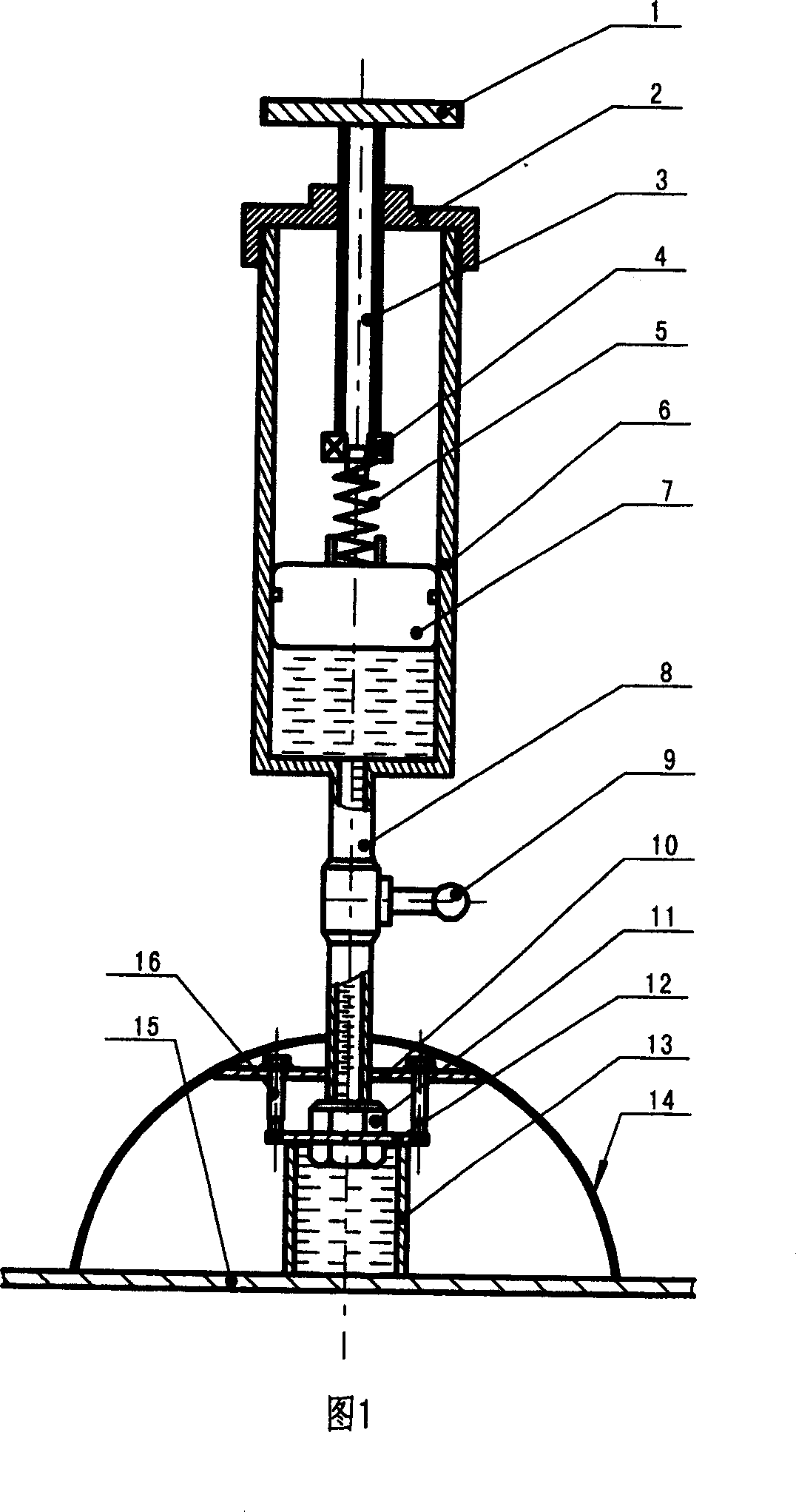

[0021] Embodiment 1: The aircraft fuel tank leakage point detection device is provided with hydraulic power by the liquid supply cylinder 6, an oil pipe 8 is connected to the oil outlet of the liquid supply cylinder, and a pressure gauge 9 is installed on the oil pipe. The oil pipe passes through the negative pressure cover 14 and fixes a sealing cover plate 12 in a threaded manner through the upper and lower screw nuts 11 on the outer edge of the end of the oil pipe. Under this sealing cover plate, the leak detection box 13 is axially fixed, and its sealing method is to paste the nut and the leak detection box together with glue to play a sealing role. Negative pressure cover and leak detection box are all placed on the aircraft fuel tank 15. A pressure regulating ring plate 10 is fixed axially upward in the negative pressure cover through the struts 16 uniformly distributed and fixed on the outer edge of the sealing cover plate, and the pressure regulating ring is supported ...

Embodiment 2

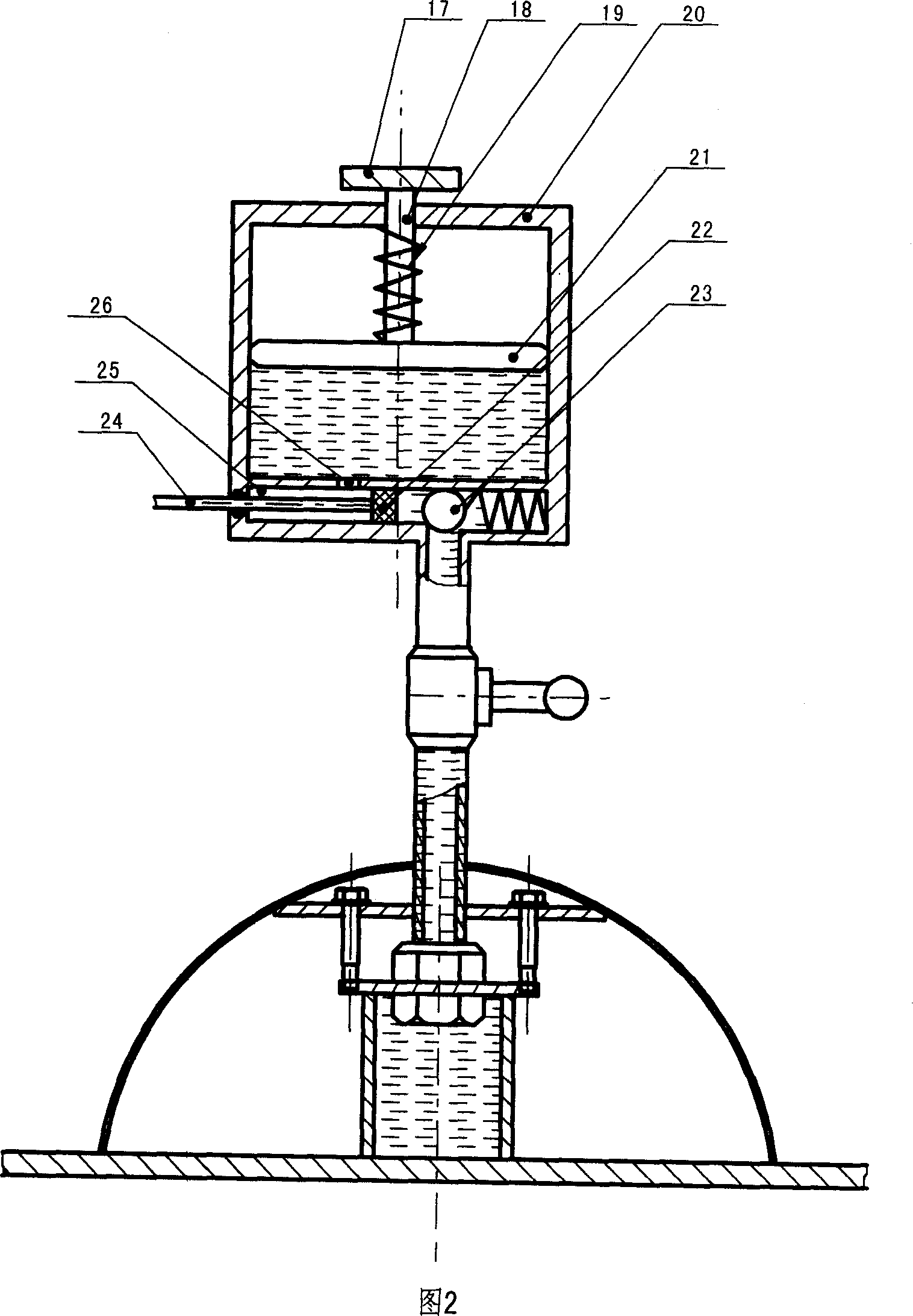

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is only in the configuration of the liquid supply cylinder. The structure of the liquid supply cylinder is as follows: a liquid supply cavity 25 connected to the oil pipe is provided at the bottom of the liquid supply cylinder 20 , a one-way valve 23 is installed at the communication part between the liquid supply chamber and the oil pipe, the liquid supply chamber is connected to the liquid supply cylinder through the oil inlet 26, and an oil injection piston 22 runs in the liquid supply chamber, and the oil injection piston is connected through the valve stem 18 Valve rod 24 outside the oil supply cylinder. A buffer spring 19 and a pressure handle 17 are axially installed on the piston 21 of the liquid supply cylinder.

[0026] Other structures of Embodiment 2 are the same as those of Embodiment 1, and will not be repeated here.

[0027] The working principle of the liquid supply cylinder in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com