Mobile contact line of electrified railway

A technology of electrified railway and catenary, applied in the direction of overhead lines, etc., can solve the problems of heavy maintenance workload, low fuel utilization rate, high operating cost, etc., and achieve the effect of small maintenance workload, high driving speed and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

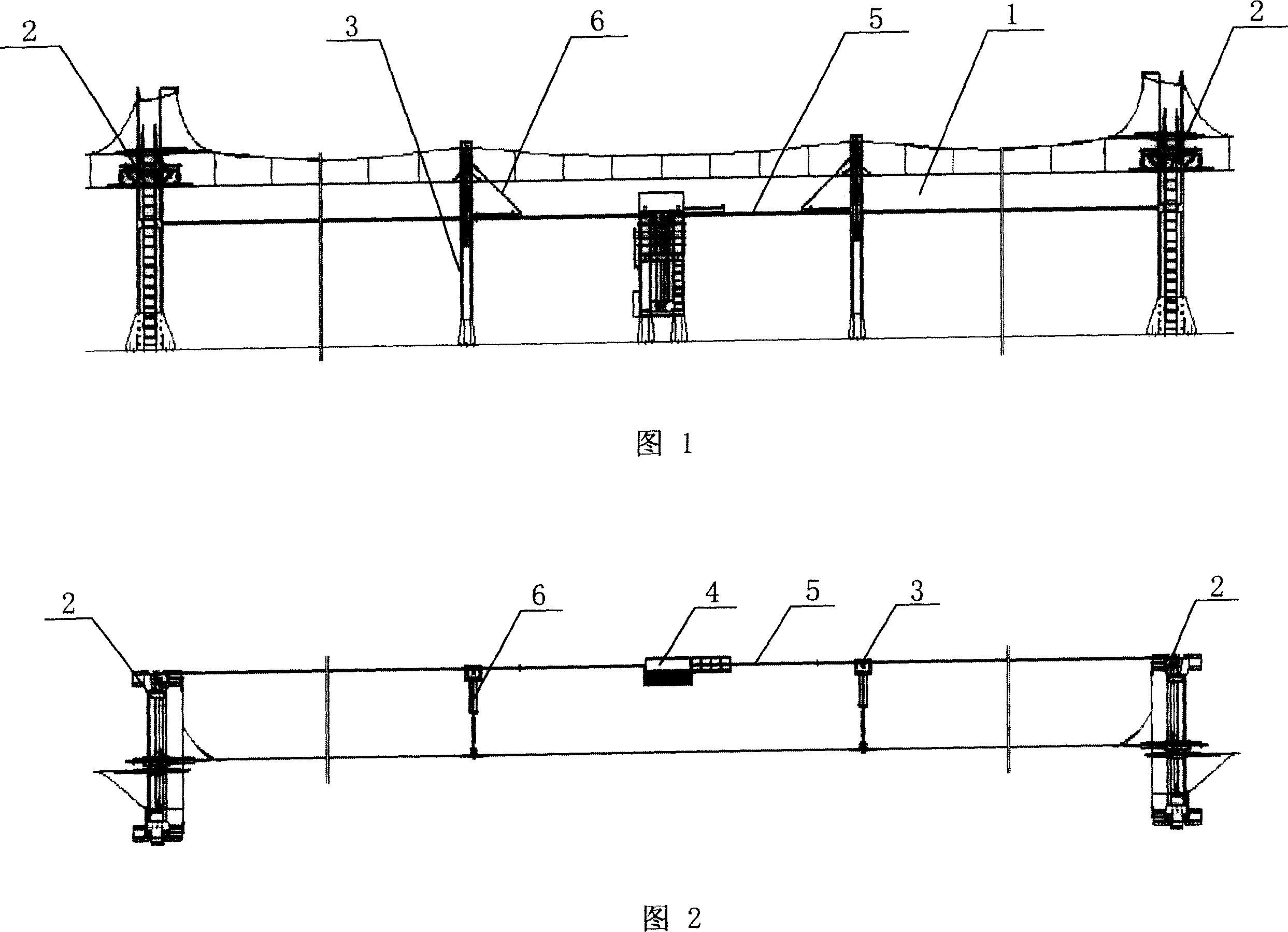

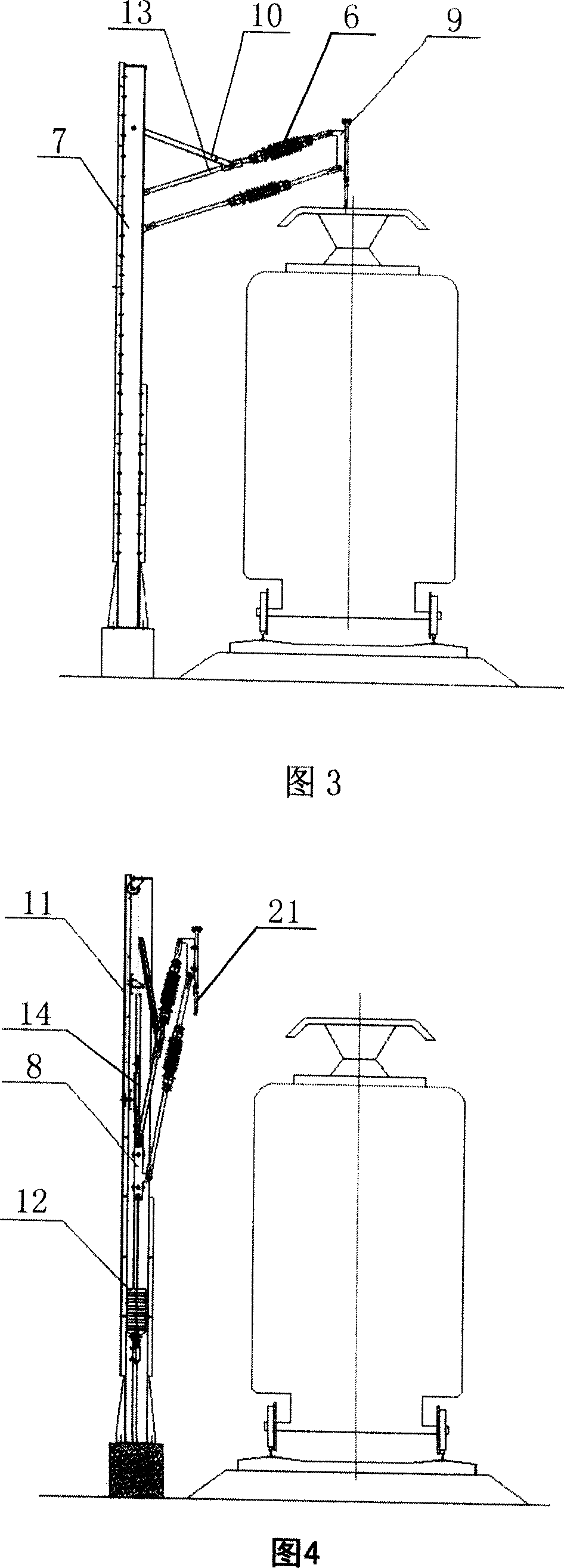

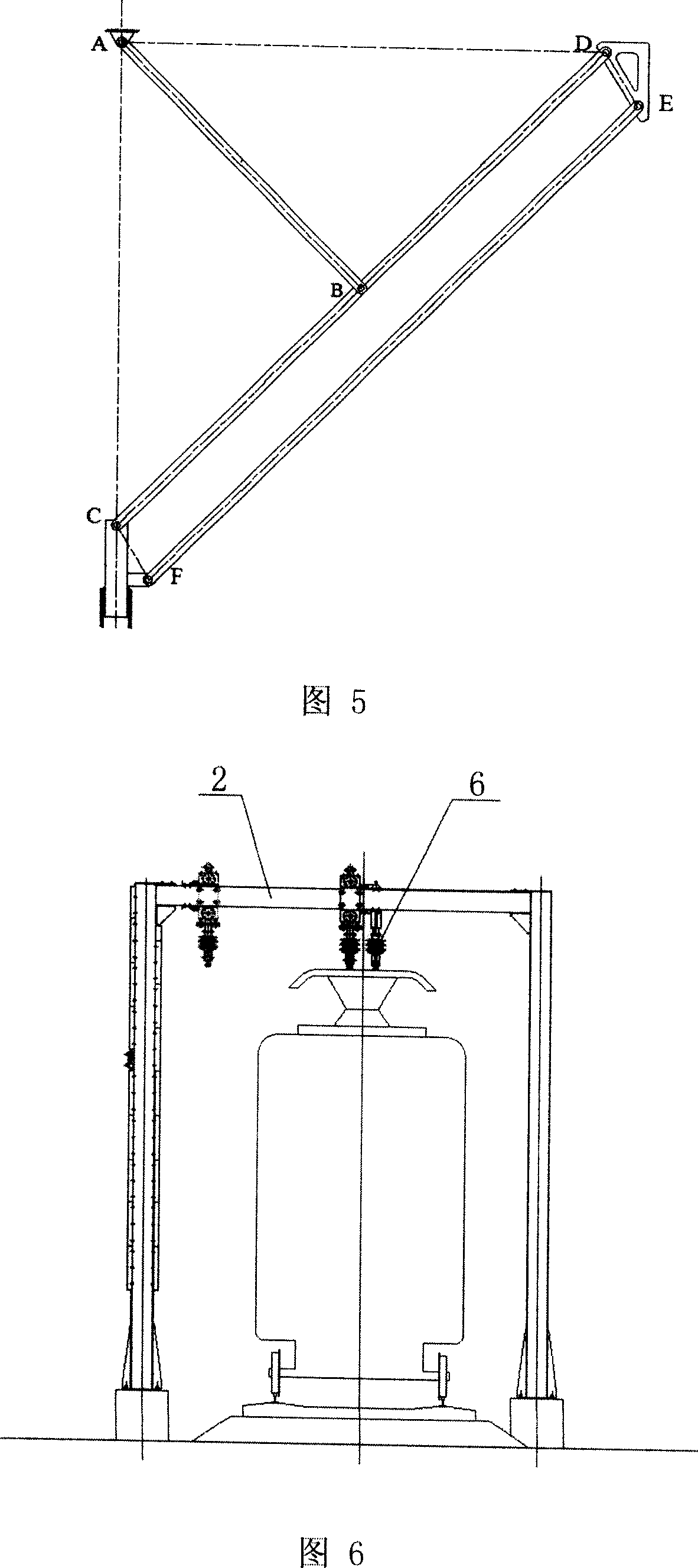

[0032] Below in conjunction with specific embodiment, the present invention is described further:

[0033] Referring to Fig. 1 and Fig. 2, Fig. 1 is a schematic diagram of the overall structure of the movable catenary of the electrified railway of the present invention; Fig. 1 is a top view of the overall structure of the present invention; the movable catenary of the electrified railway adopts a flexible simple chain suspension full compensation catenary structure ; It consists of a translation arm support device 3 equipped with a parallelogram combined arm arm with a crank slider mechanism, a transition section gantry 2 with a compensation walking device for the anchor section, a pulley type tension spring compensation device 20, and an elastic suspension locator 21 etc.; the overall translation of the catenary is driven by the motor 4 installed on the traction power frame through the traction steel rope 5.

[0034] The scope of the loading and unloading operation area is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com