Process for preparing high concentration phosphoric acid from middle-and low-grade phosphorus ore

A low-grade, high-concentration technology, applied in the direction of phosphoric acid, phosphate, phosphorus oxyacid, etc., can solve the problems of large investment and inoperability, and achieve the goal of reducing total investment, saving pre-treatment costs, and saving concentration costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

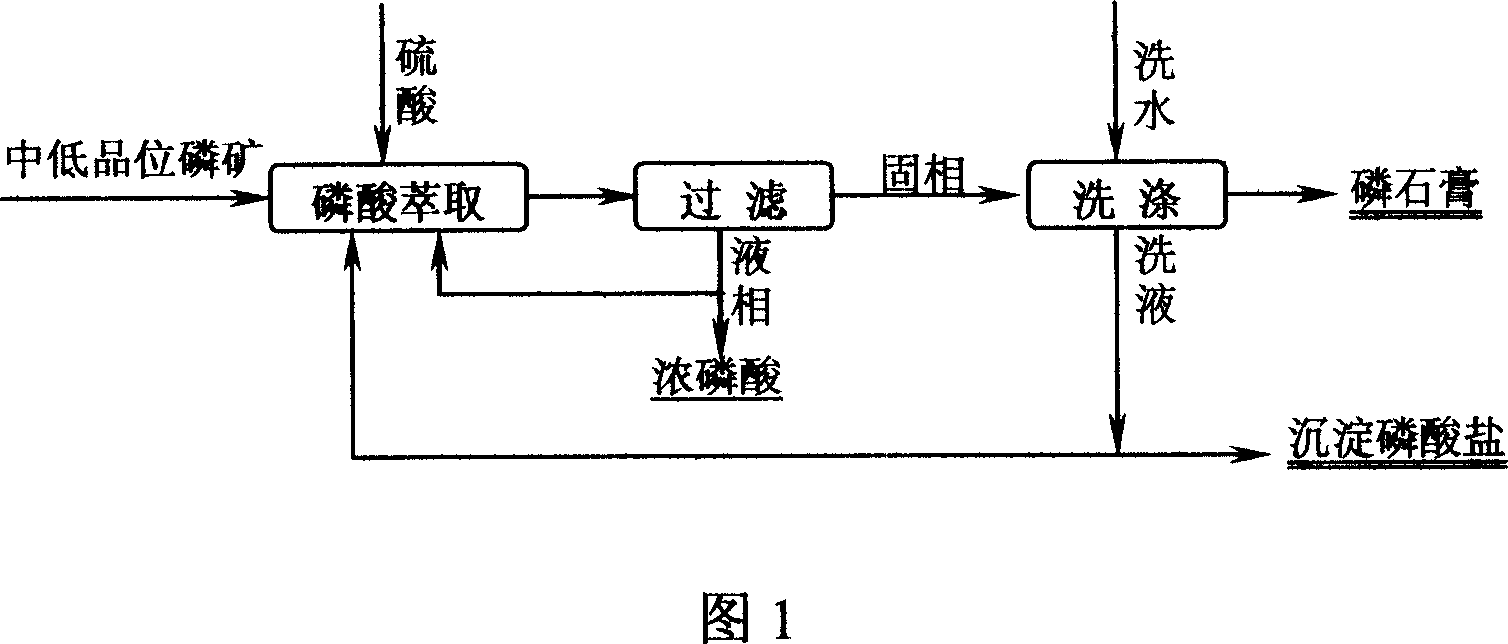

Method used

Image

Examples

example 1

[0040] 1.1 Preparation of base acid

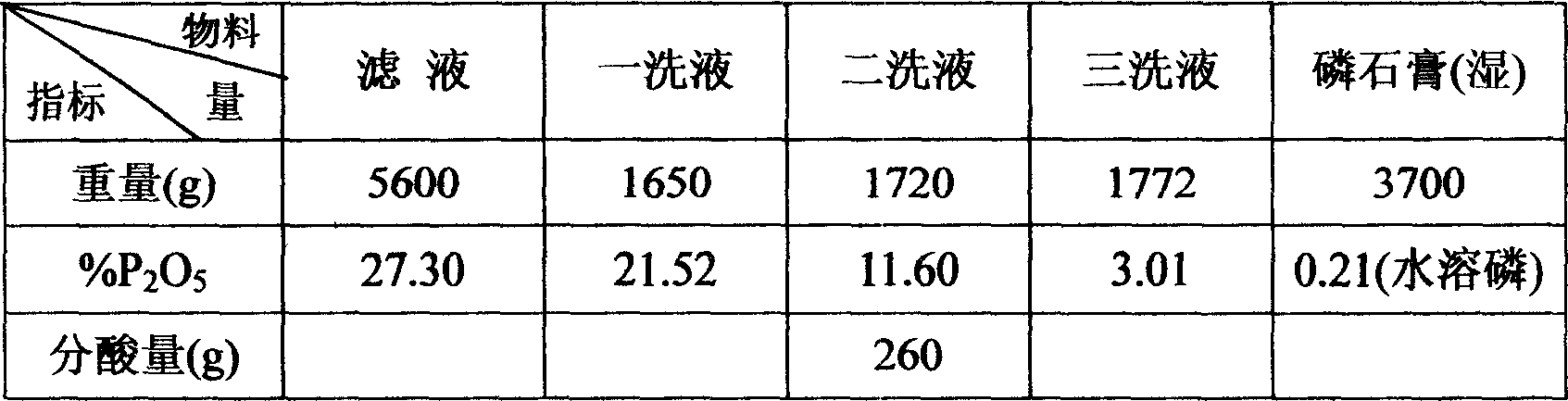

[0041] Weigh phosphate rock powder 12000g (P 2 o 5 % 20.6), according to the traditional method of extracting phosphoric acid, the concentration of phosphoric acid is divided into six times, using 2000g of rock phosphate powder each time, the first extraction adopts tap water to adjust the liquid-solid ratio, filters after the reaction is completed, and washes the filtrate and The first wash is used as the base acid for the second extraction of phosphoric acid, the second wash and the third wash are respectively used as the first wash and the second wash of the acid filter cake for the next extraction, and tap water is used for the third wash. The third to sixth acid extraction tests were completed in the same way. The controlled reaction conditions are: SO 3 It is ~3.5%,; the reaction temperature is: ~°C; the extraction time is 6 hours; the liquid-solid ratio is 2.5:1. After the sixth acid extraction, the amount of phosphoric acid fil...

example 2

[0046] 2.2 Low-grade phosphate rock acid production

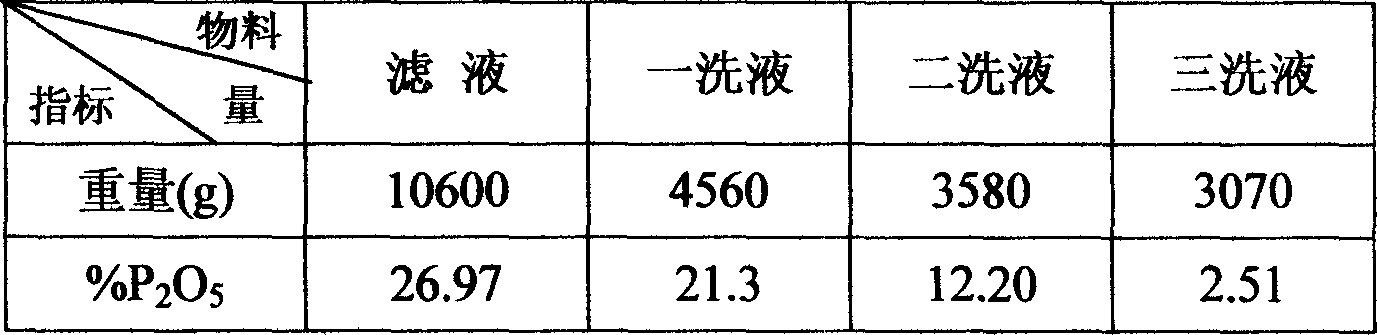

[0047] Weigh phosphate rock powder 3000g (P 2 o 5 % 24.2), adding water makes it a water-containing 35% ore slurry, according to the reaction conditions for preparing the bottom acid, the liquid-solid ratio of the bottom acid prepared above and a washing liquid to gradually adjust the reaction slurry is 3.0. The amount of filtrate used is 7970g, and the amount of one washing liquid is 3760g. After the reaction is completed, filter, and use the second washing solution for preparing the bottom acid as the first washing water, and remove 3000g in total. The third washing solution for preparing the bottom acid is all used as the second washing water for this acid extraction, and the third washing water is all clear water. For washing, share 3000g of clear water. Filtrate and lotion produced through analysis, its data are as follows:

example 3

[0050] 3.2 Low-grade phosphate rock production of acid

[0051] Weigh phosphate rock powder 1000g (P 2 o 5 % 22.1), add water to make it a water-containing 35% ore slurry, according to the reaction conditions for preparing the bottom acid, the liquid-solid ratio of the bottom acid prepared above and a washing liquid to gradually adjust the reaction slurry is 2.5. Use 1950g of filtrate, 1150g of the first wash, and 150g of the second wash. After the reaction is completed, filter, use the second washing solution for preparing the bottom acid as the first washing water, and share 950g, and all the three washing solutions for preparing the bottom acid are used as the second washing water for this acid extraction, and the third washing water is all clear water For washing, share 990g of clean water. Filtrate and lotion produced through analysis, its data are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com