Printing and dyeing sewage processing method

A treatment method, printing and dyeing sewage technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of incomplete coagulant reaction, waste of coagulant, slow reaction, etc., and achieve good sewage treatment effect and low chemical consumption Small, less residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention, because different types of coagulants such as polyaluminum chloride, aluminum sulfate, polyaluminum sulfate, polyferric sulfate, ferrous sulfate or ferric chloride can react in a short time when mixed to form Inorganic polymer form, so the coagulant and composite element (or composite substance) used in the present invention can be the same kind of substance, but in specific use, the same substance cannot be used as the mixture in the dosing pipeline 2 and the additional pipeline 3. Coagulants and compounding elements.

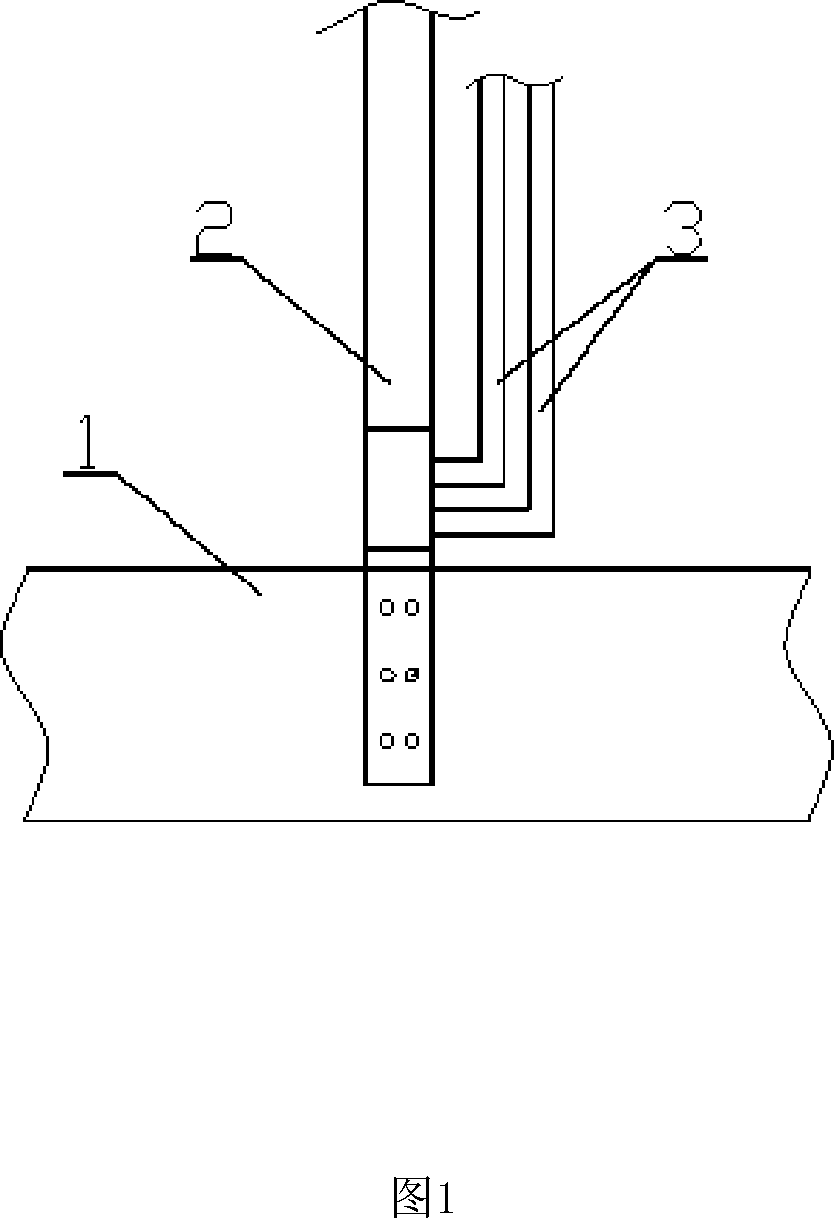

[0014] As shown in Figure 1, a dosing pipeline 2 is set on the sewage pipeline 1 of the flowing printing and dyeing sewage, and an additional pipeline 3 is connected to the side of the dosing pipeline 2, and coagulant is added through the dosing pipeline 2, and the added mixture The coagulant is polyaluminum chloride and can also be aluminum sulfate, polyaluminum sulfate, polyferric sulfate, ferrous sulfate or ferri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com