Methods and devices for aseptic irrigation, urine sampling, and flow control of urine from a catheterized bladder

a catheterized bladder and aseptic technology, applied in the field of catheterized bladder aseptic irrigation, urine sampling, flow control, etc., can solve the problems of clinicians at risk of occupational injury related to bio-hazardous waste exposure, numerous safety issues, and many health and safety issues for patients, medical personnel, and the community, and achieve easy sanitization, increase the increment of time, and easy collection of urine samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

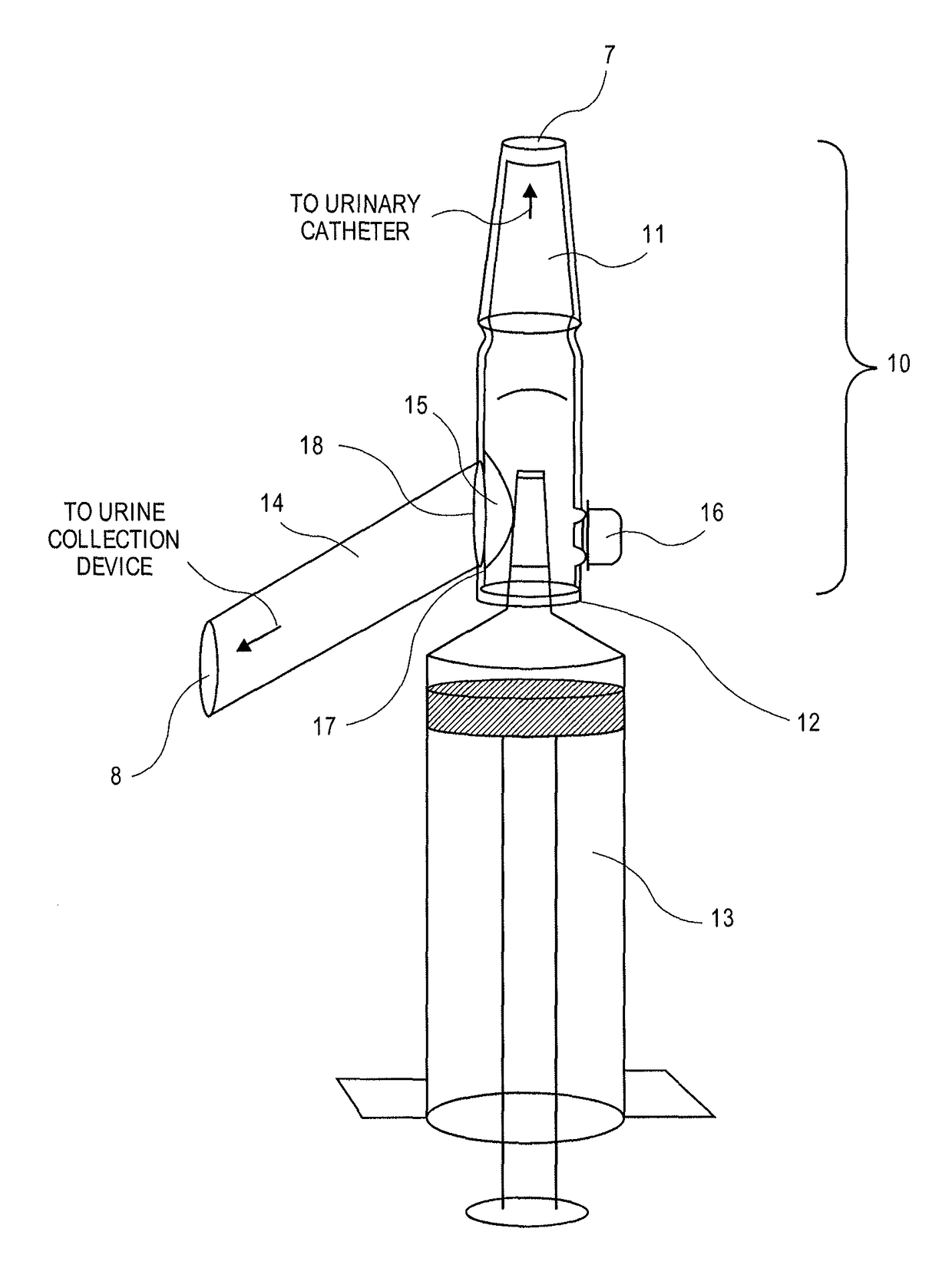

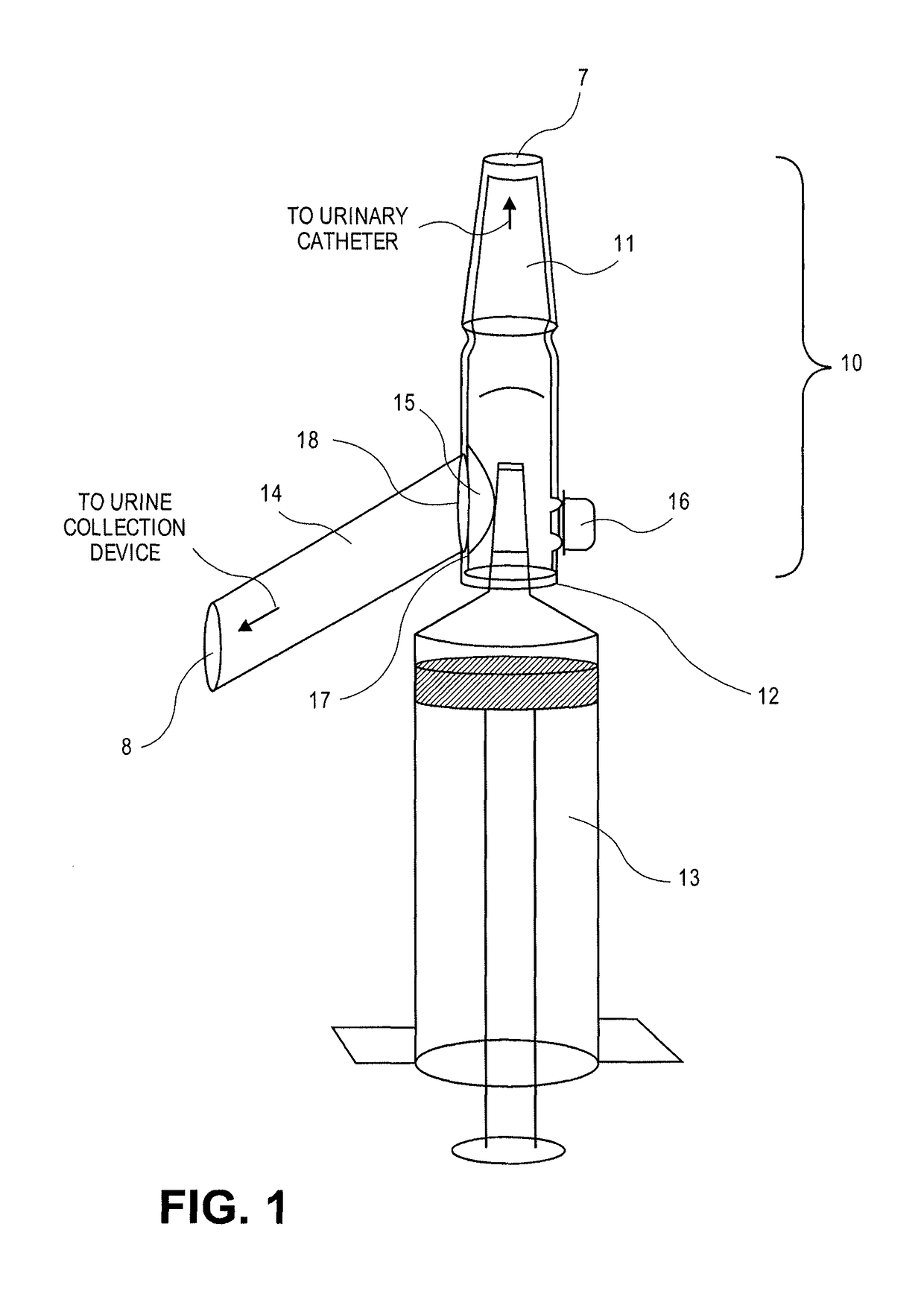

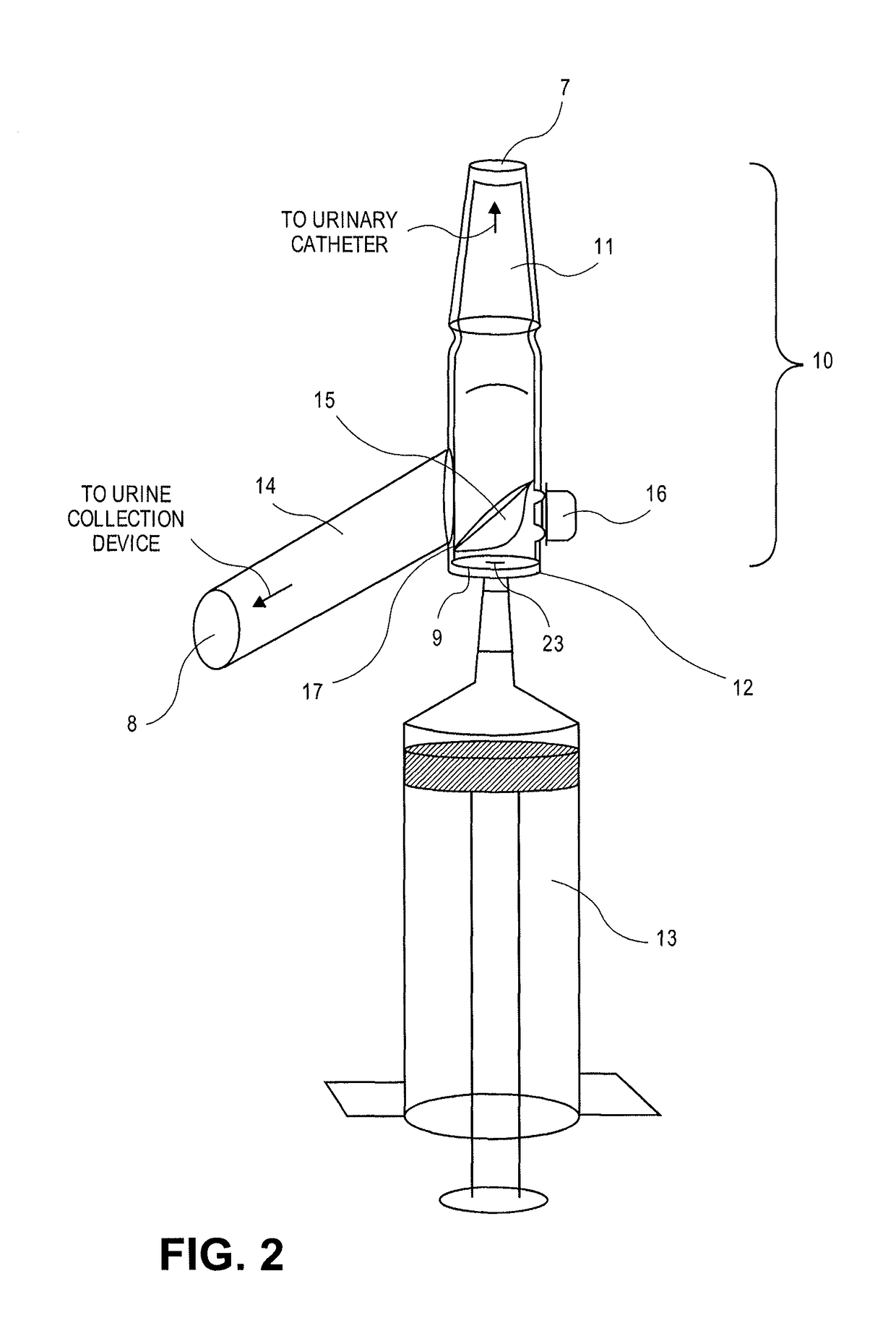

[0057]The following description and drawings are illustrative and are not to be construed as limiting. Numerous specific details are described to provide a thorough understanding. However, in certain instances, well known or conventional details may not be described in order to avoid obscuring the description. In accordance with the present invention, a novel and improved system for aseptic irrigation and urine specimen collection and / or for disconnection of urine collection device from a catheterized bladder is provided.

[0058]The devices, systems, and methods described herein solve the problem of disconnection and potential exposure to contaminants during irrigation and urine sampling by providing a port valve assembly that attaches at one port to the catheter, at a second port to the urinary collection device, and at a third port to an irrigation / sampling syringe. Some or all of the ports can be protected by slit membranes. The slit membranes described herein can advantageously be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com