Motor controller power switch arrangement

a technology for motor controllers and power switches, applied in the direction of motor/generator/converter stoppers, electronic commutators, dynamo-electric converter control, etc., can solve the problems of increased electrical inductance, increased physical space and electrical conductors, and other switching problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] General

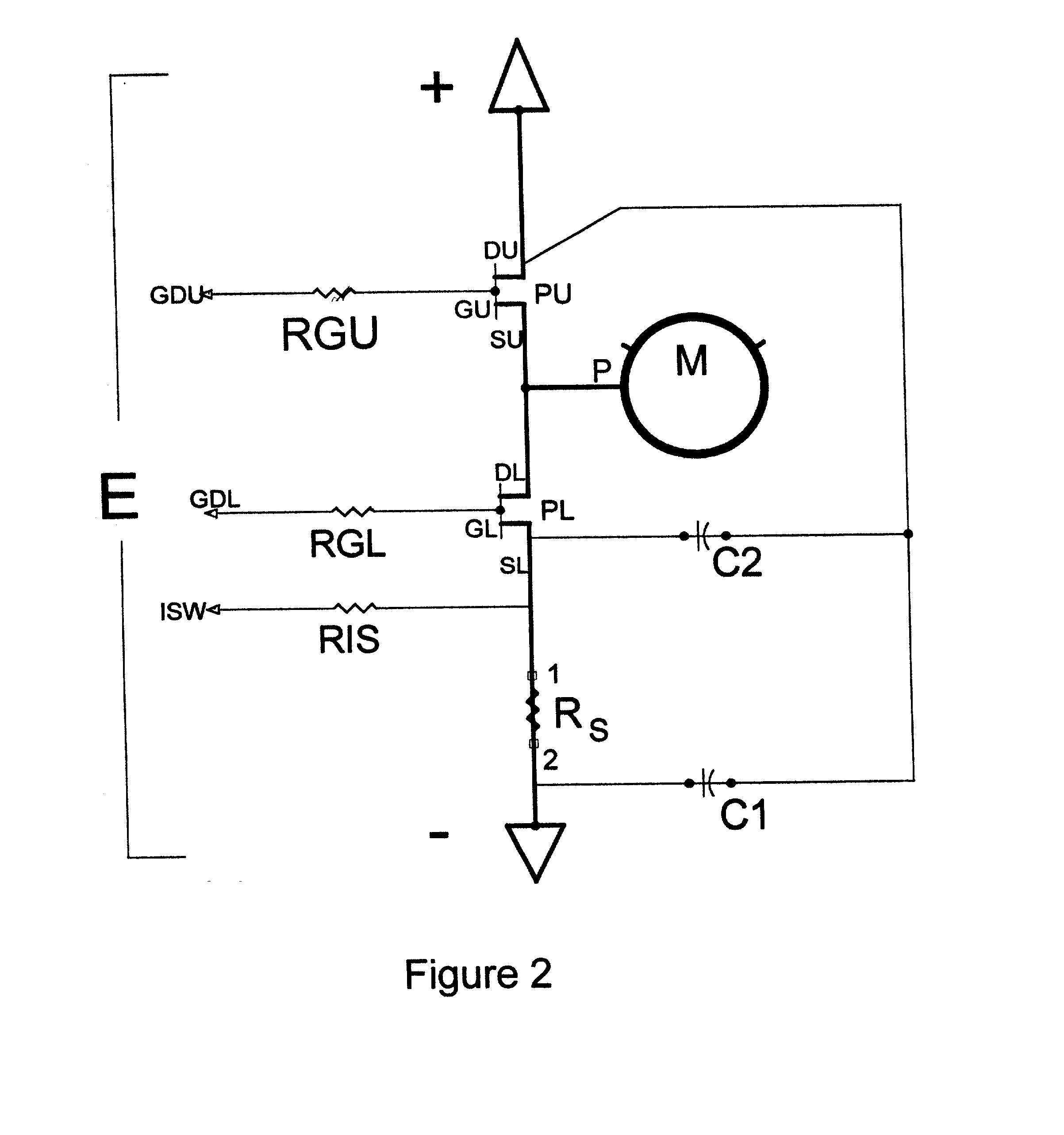

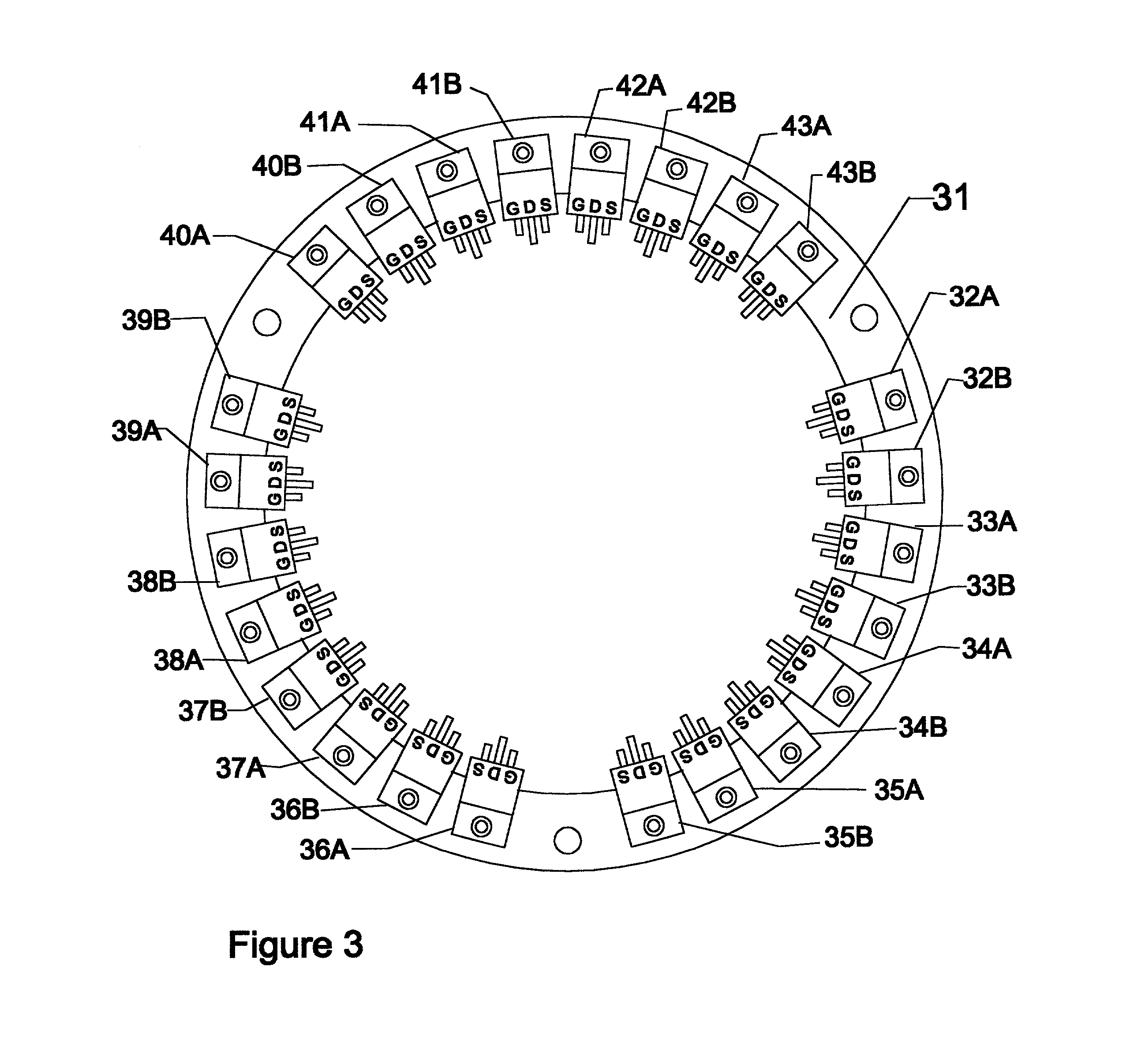

[0029] The present invention is concerned primarily with advantages which accrue from preferred physical arrangements of the power circuits for an inverter. A secondary benefit allows for the measurement of the current and power in the various controlling electronic switches, and for the control by fine adjustment of these switches so as to achieve various optimizations.

[0030] An inverter is required whenever DC (direct current) is used as the power source to operate an AC (alternating current) motor. Modern inverters employ semiconductor power electronic switches, under various types of control, to accomplish this conversion.

[0031] The present invention revolves about the arrangement of the power semiconductors and circuits in such inverters, as well as the provision of signals to the control apparatus for optimally "fine tuning" the system to achieve certain performance enhancements.

[0032] Typical Power Circuitry

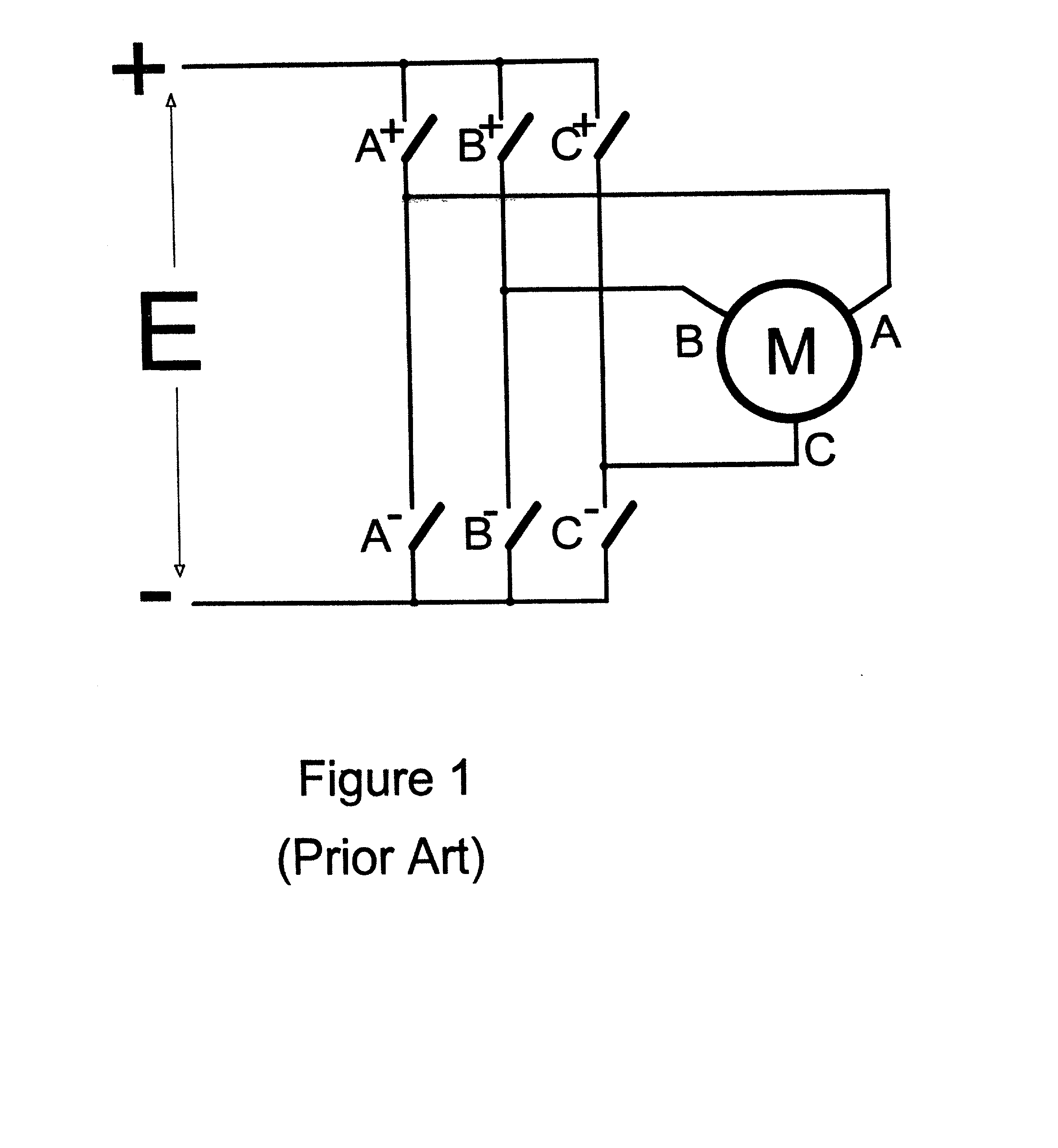

[0033] The power switching portion of a typical inverte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com