High-power external-cavity optically-pumped semiconductor lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

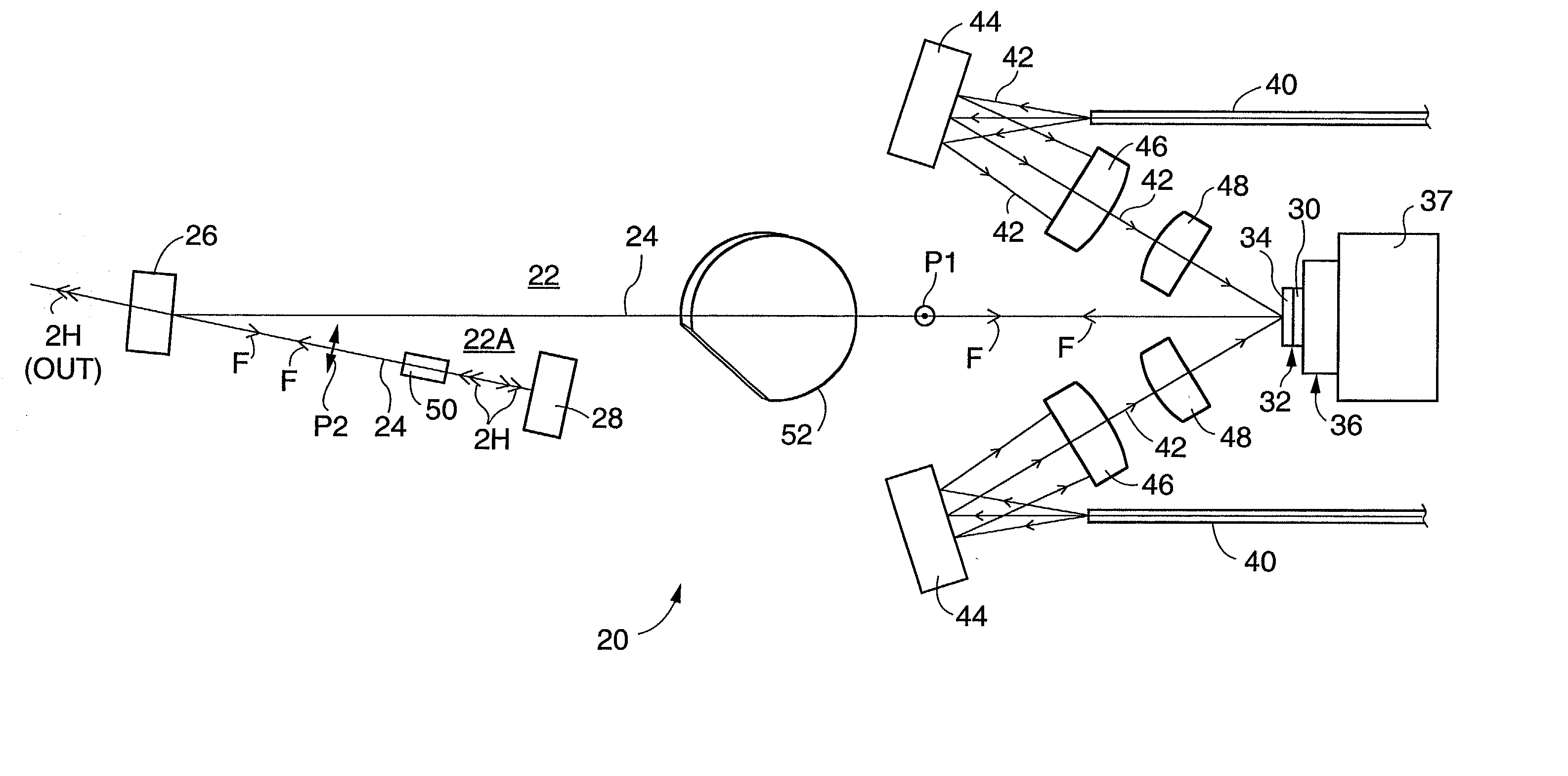

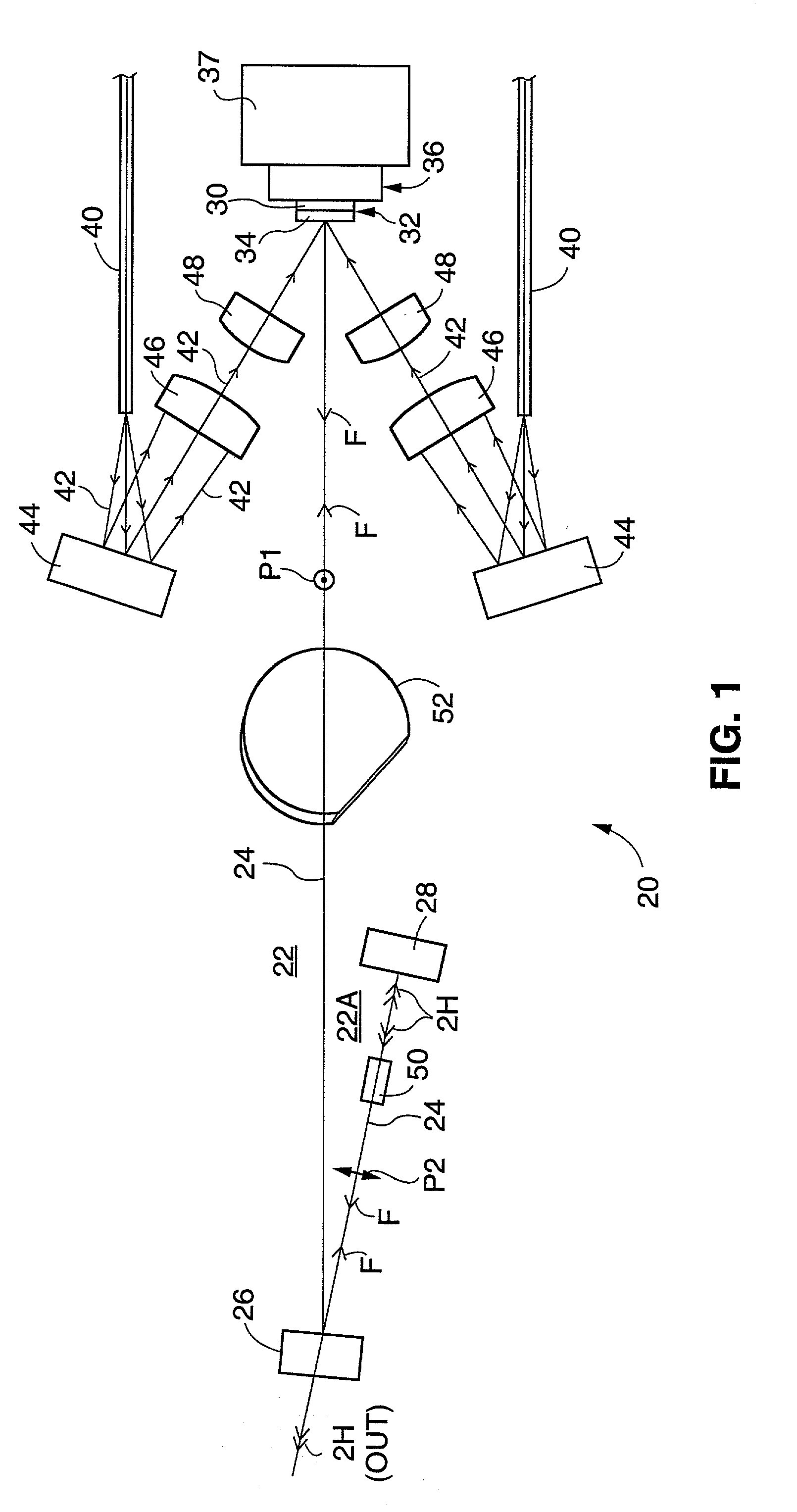

radiation having a wavelength half of the fundamental wavelength.

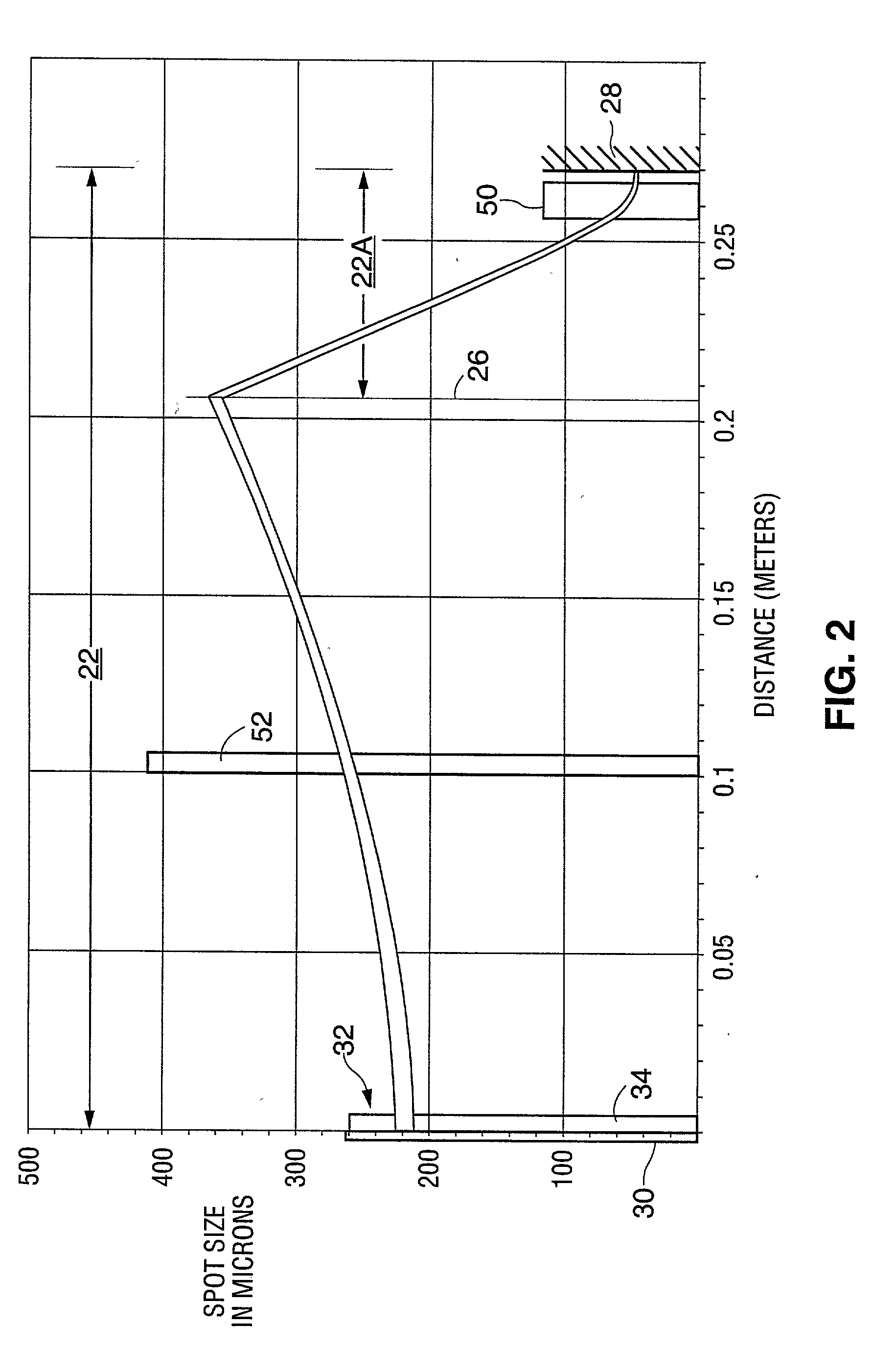

[0013] The laser-resonator, the optically nonlinear-crystal, the OPS-structure, the heat-sink arrangement and the optical pump-light-delivering arrangement are selected and arranged such that the resonator delivers the frequency-doubled radiation as output-radiation having a wavelength between about 212 nanometers and 900 nanometers at an output-power greater than about 100 milliwatts. The laser preferably has a resonator length greater than about 5.0 cm

[0014] In one embodiment of a high-power OPS-laser in accordance with the present invention, stable, single axial-mode, CW laser output-power of about 4.0 W at 488 nm wavelength is achieved by intracavity frequency-doubling 976 nm radiation from a single OPS-structure using an optically-nonlinear crystal of lithium triborate (LBO) in a resonator having a length of about twenty-five centimeters (cm). The OPS-structure has active layers of an In.sub.0.18Ga.sub.0.82As comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com