Thin film semiconductor and method for manufacturing the same, semiconductor device and method for manufacturing the same

a technology of thin film semiconductor and manufacturing method, which is applied in the direction of transistors, crystal growth process, chemistry apparatus and processes, etc., can solve the problems of grain obstruction, high density of crystal nuclei, and unsatisfactory thin film transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 2

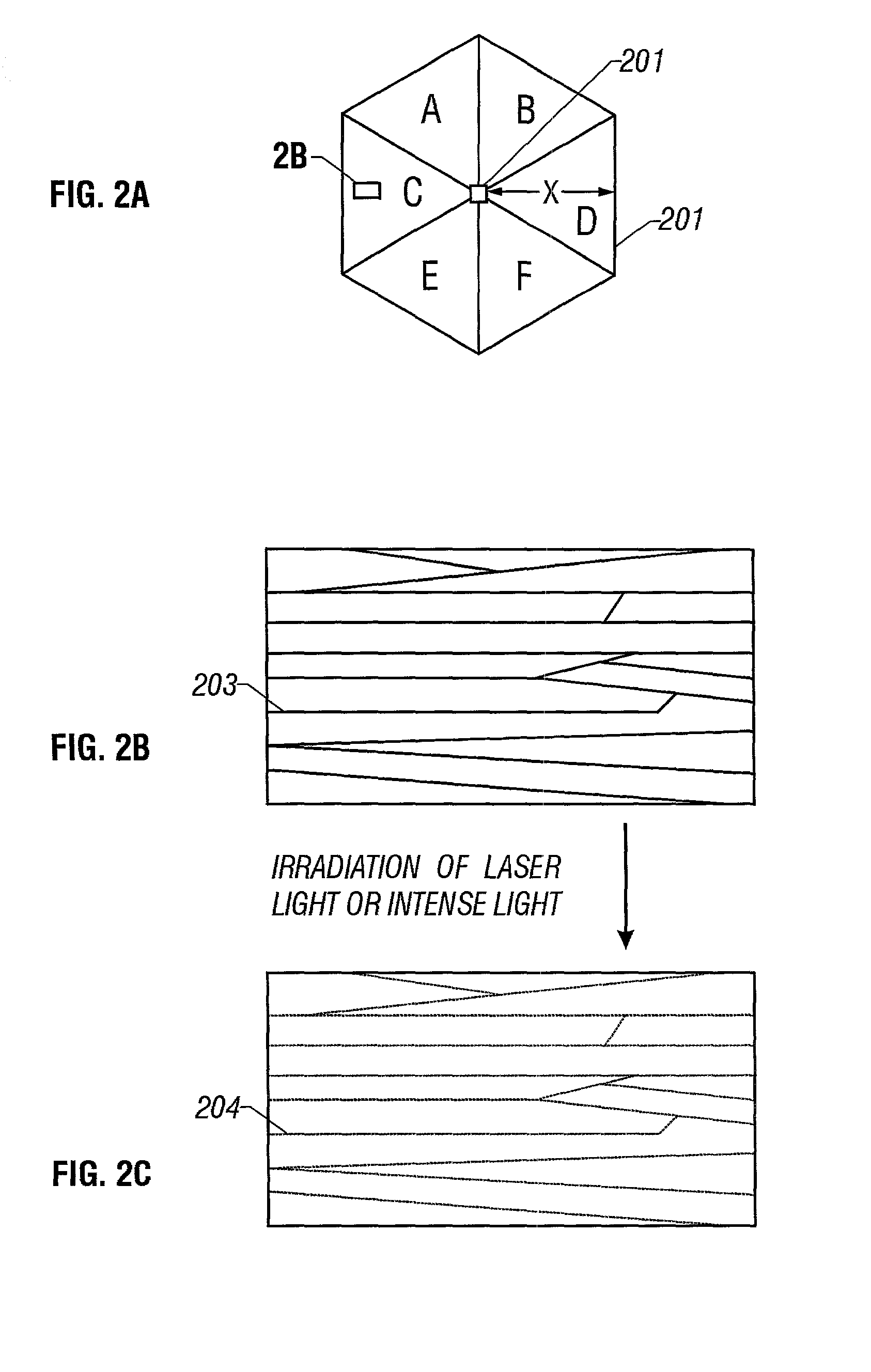

[0119] The present embodiment refers to a constitution similar to that described in Embodiment 1, except that the irradiation of a laser light is replaced by the same of an intense light having an energy equivalent to that of the laser light. RTA (rapid thermal annealing) is known as a technique for implementing the constitution of the present embodiment.

[0120] RTA is a method which comprises irradiating an intense light such as an infrared light or an ultraviolet light to the object by using a lamp, etc. The method is characterized in that the treatment can be completed in a short period of time of about several to several tens of seconds, and it can be conducted at a high heating and cooling rates. Thus, the thin film on the outermost surface alone can be heated. More specifically, for instance, only the thin film formed on the surface of a glass substrate can be annealed at an extremely high temperature of about 1,000.degree. C.

[0121] In this method, the throughput also can be co...

embodiment 3

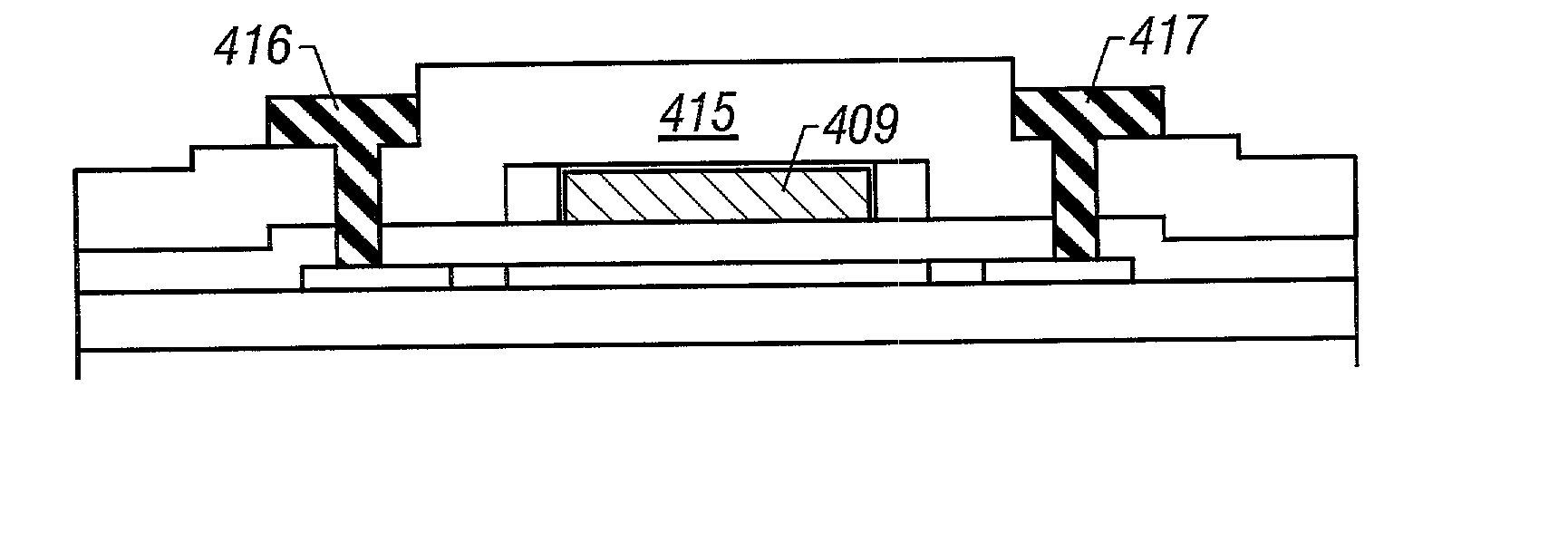

[0122] The present embodiment refers to a constitution in which an active layer of a thin film transistor is constructed by using a monodomain region obtained in the process steps described in Embodiment 1. Although a top gate type constitution is described in the present embodiment, it is also possible to apply the constitution to a bottom gate type.

[0123] Referring to FIG. 4(A), a thin film semiconductor comprising a monodomain region is formed in accordance with the process steps described in Embodiment 1, and is patterned to form an active layer 403 consisting of monodomain region alone. Similarly, as is described in Embodiment 1, reference numeral 401 is a glass substrate and reference numeral 402 is a silicon oxide film.

[0124] Then, a 1,500 .ANG. thick silicon oxide film 404 which functions as a gate insulating film is formed by plasma CVD. A silicon oxynitride film or a silicon nitride film may be used in the place of the silicon oxide film.

[0125] A 5,000-.ANG.-thick aluminum...

embodiment 4

[0148] Recently, a structure comprising a single crystal formed on a silicon substrate having a silicon oxide film interposed therebetween, i.e., the so-called SOI structure, is attracting much attention. As a break through for a device of low energy consumption, the study on an SOI structure is in a rapid progress.

[0149] Substantially, the monodomain region according to the present invention has a crystallinity well equivalent to that of a single crystal. Accordingly, it can be readily applied to a SO technique. In the present invention, problems yet to be solved for an SOI substrate is considered in comparison with the present invention.

[0150] The problems remaining yet to be solved in the SOI technique are summarized in FIG. 5. Referring to FIG. 5, it can be seen that the problems include those related to crystallinity, such as the interface density level in the silicon film and fixed charges, and those attributed to external factors, such as metallic contamination and boron conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com