Fused-silica capillaries with photopolymer components

a technology of photopolymer and capillary column, applied in the field of capillaries, can solve the problems of reducing the efficiencies of the capillary column, unable to selectivity for uncharged analytes in cze, and remained more problemati

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

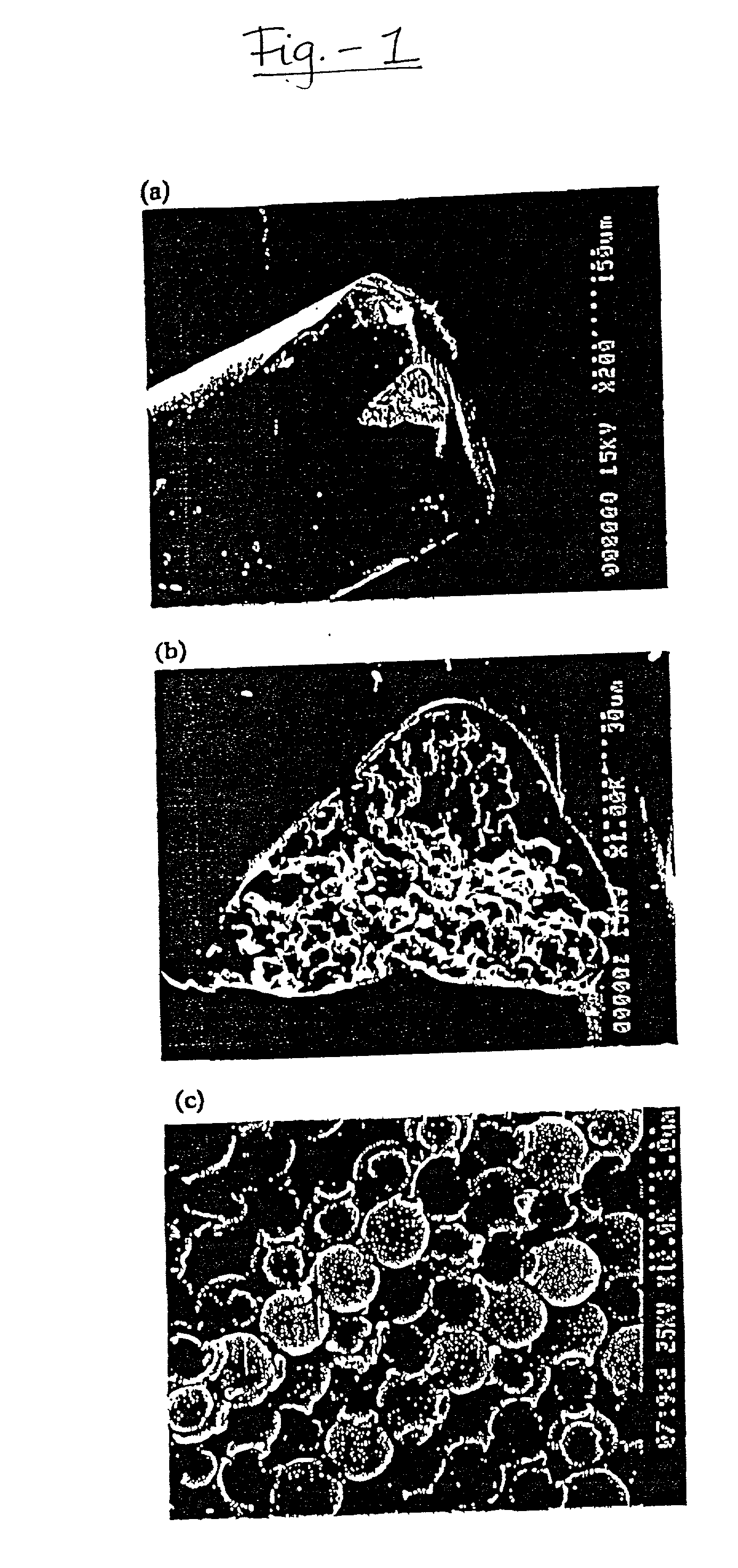

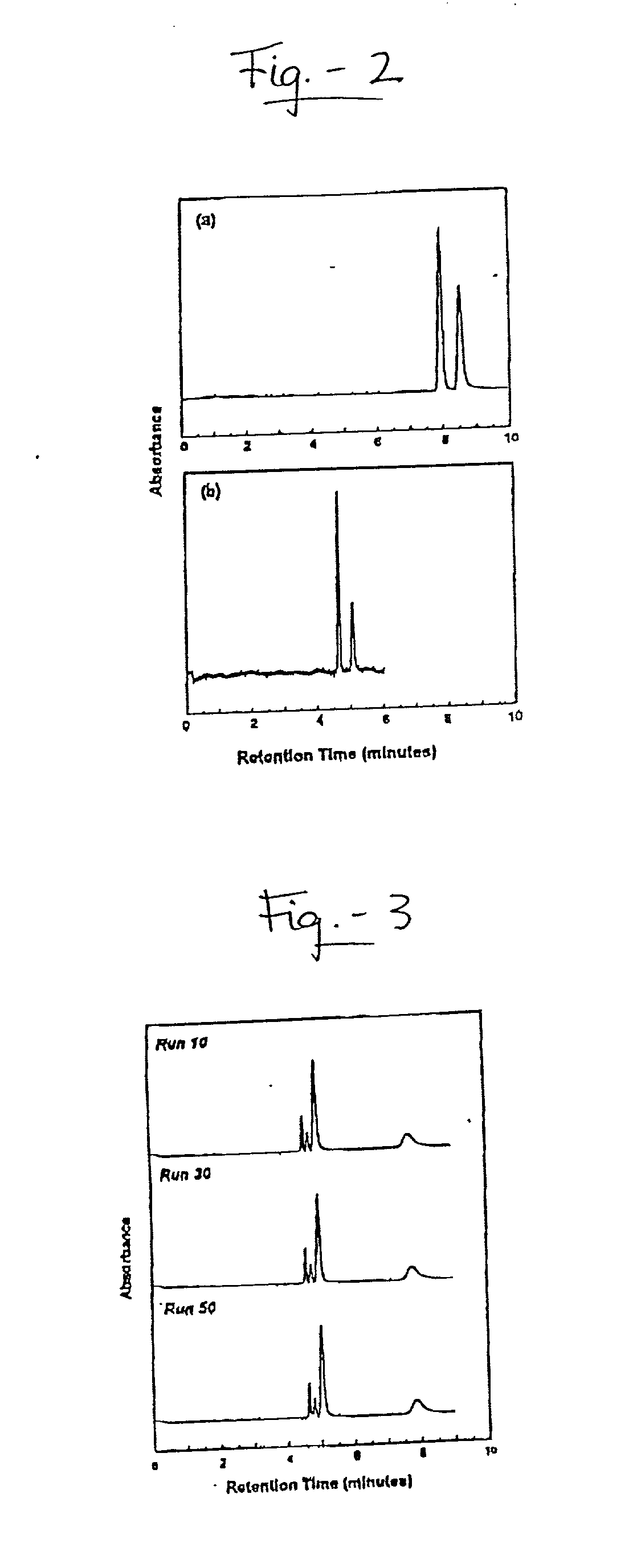

Image

Examples

Embodiment Construction

[0031] Materials. The monomers trimethylolpropane trimethacrylate (TRIM) and 2,3-epoxypropyl methacrylate (glycidyl methacrylate, GMA) were of the highest purity available from Aldrich (Milwaukee, Wis.). Toluene and 2,2,4-trimethylpentane (isooctane) from Sigma (St. Louis, Mo.) were used as porogenic solvents. The fused capillaries used in this study were purchased from Polymicro Technologies (Phoenix, Ariz.). The 1.5 .mu.m spherical ODS particles were provided by Micra Scientific, Inc. (Lafayette, Ind.), .alpha.-Methoxy-.alpha.-phenylactophenone (benzoin methyl ether, 99%), thiourea, benzaldehyde, benzyl alcohol, 2-methylnaphthalene, sodium phosphate, and acetonitrile (HPLC grade) were purchased from Aldrich (Milwaukee, Wis.). Water was purified with an Ultrapure water system from millipore (Milford, Mass.).

[0032] Polymerization Procedure. The photopolymerization procedure was carried out as previously described (Viklund et al., Chem. Mater., 9, pp. 463-471, 1997). In situ free-rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| inner diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com