Control cable

a control cable and cable technology, applied in the direction of rigid pipes, water mains, service pipes, etc., can solve the problems of inability to meet the requirements of high-quality alloy steel, disadvantages of dissimilar metals in marine environments, and associated costs of referred techniques, so as to reduce the cost of materials, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

with references to the enclosed drawings, where

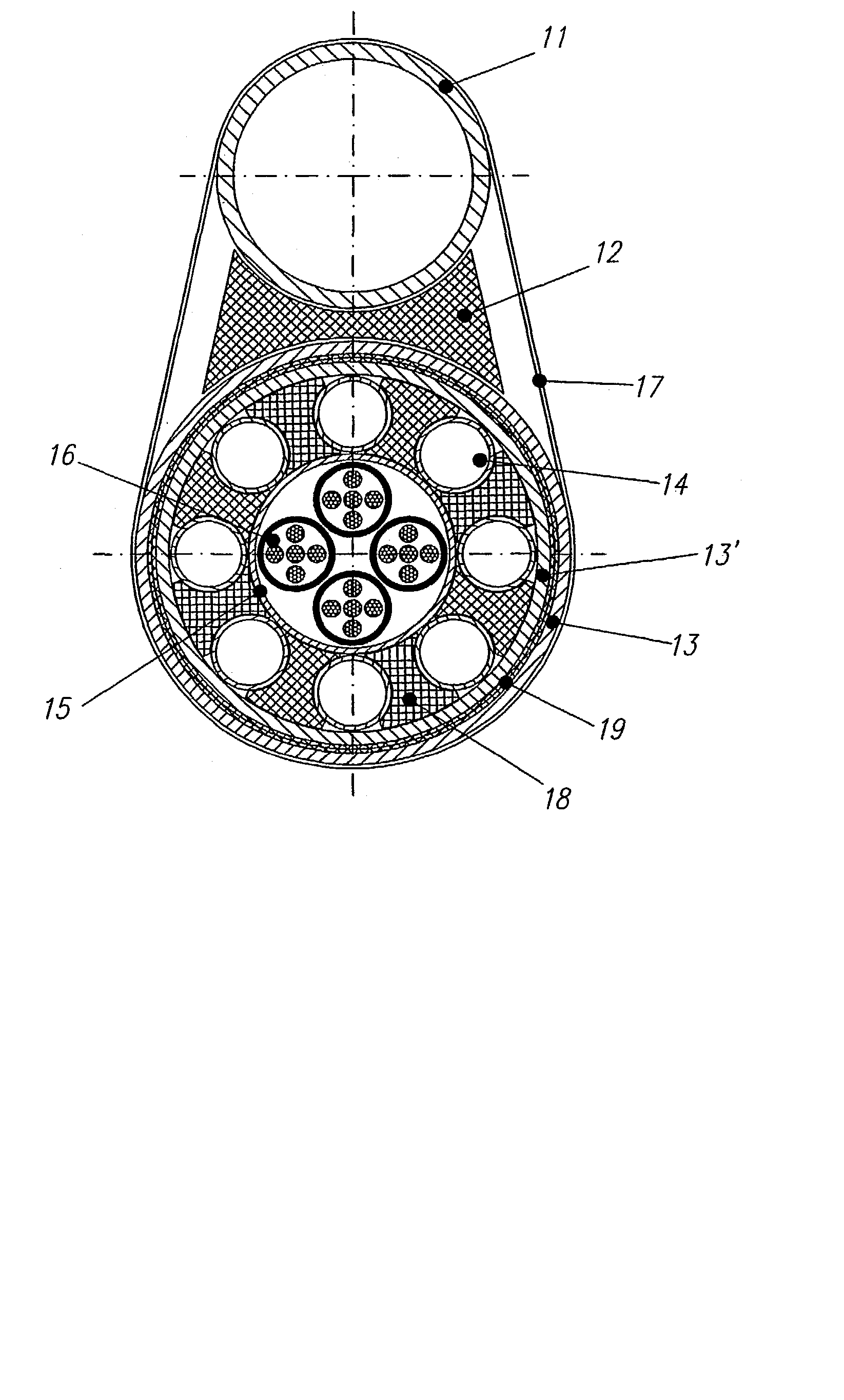

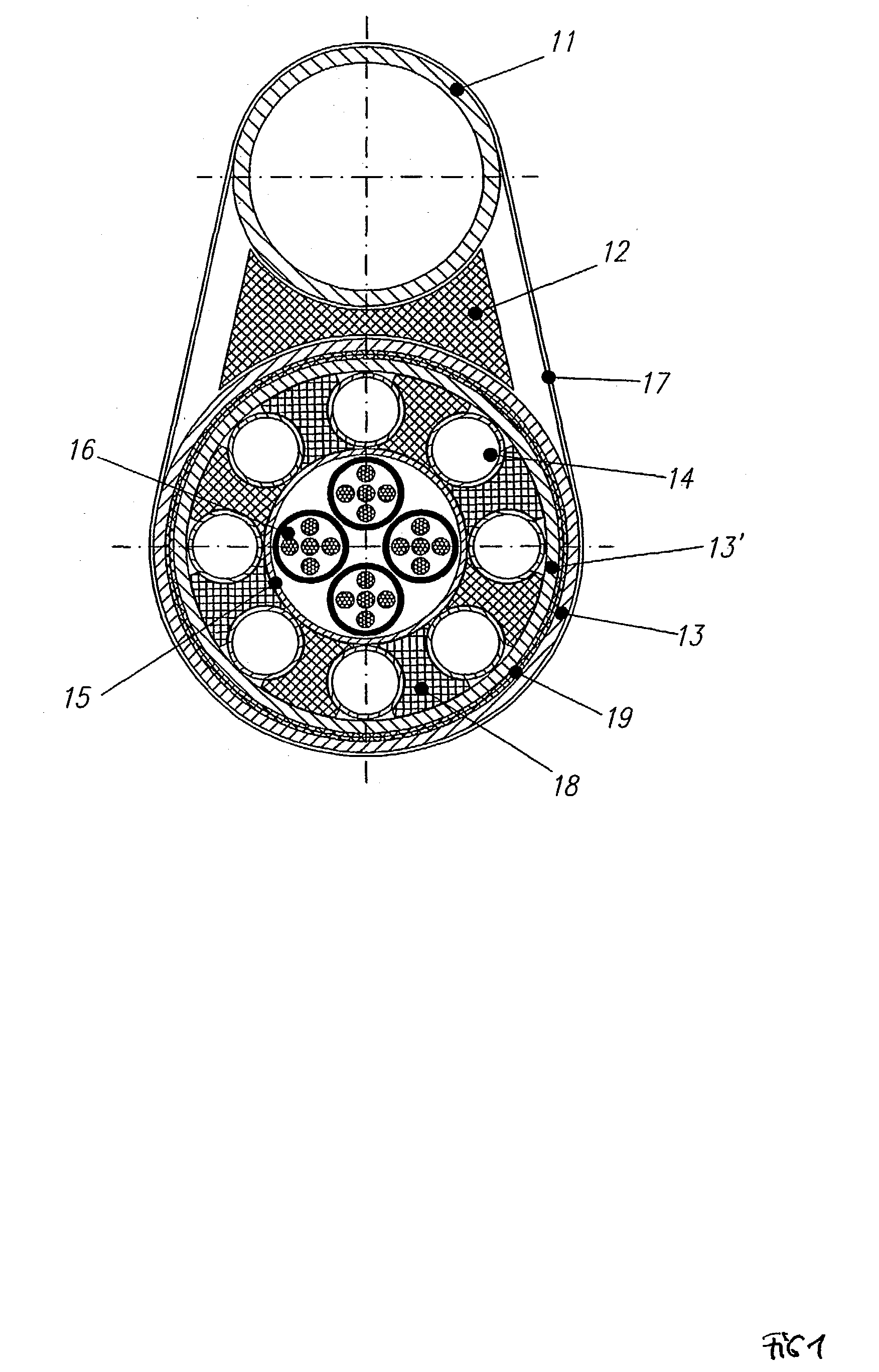

[0015] FIG. 1 shows a service umbilical cord according to state-of-the-art

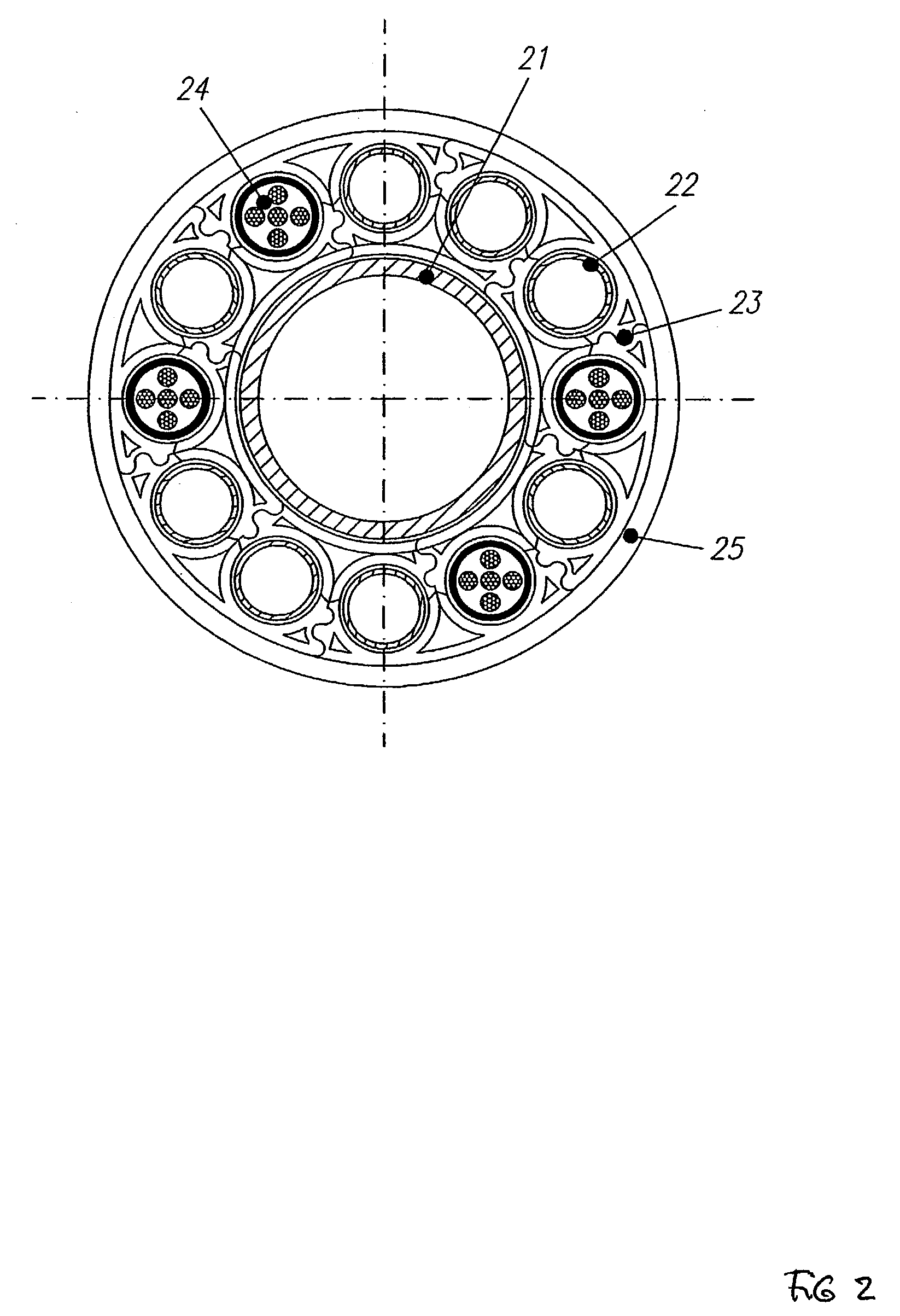

[0016] FIG. 2 shows another service umbilical cord according to state-of-the-art.

[0017] FIG. 3 shows a design of an integrated service umbilical cord according to the present invention

[0018] FIG. 4 shows the principle for conventional hydraulic control of a down hole safety valve, and

[0019] FIG. 5 shows a schematic of the hydraulic control circuits of a control module according to the invention

[0020] The concept is based on use of a regular 2-4" pipe in carbon steel as carrier pipe and conduit for hydrate inhibitor 31. This pipe also provides mechanical protection, stress relief and corrosion protection for all the internal components. All small bore tubing such as conduits for supply of chemicals 32, conduits for hydraulic power fluid (control system) and electrical conductors 33 are accommodated inside the outer carrier 31. The concept is illustrated in FIG. 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com