Lift off cylinder for axial piston hydraulic pump

a hydraulic pump and axial piston technology, applied in the direction of mechanical equipment, fluid hybrid vehicles, engines with rotating cylinders, etc., can solve the problems of residual drag factor, seal, bearing, bearing, etc., and the system described, subject to several significant limitations,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0074] the invention is shown in FIGS. 3 and 4, wherein like features are denoted by corresponding reference numerals. In this embodiment, the pump / motor unit incorporates a secondary aspect of the invention, in the form of controllable bias means disposed to apply a variable bias force urging the mating faces 21 and 22 on the valve plate and the cylinder block respectively into sealing engagement. The bias means include an hydraulic hold-down piston 30 disposed within a complementary hold-down cylinder 32.

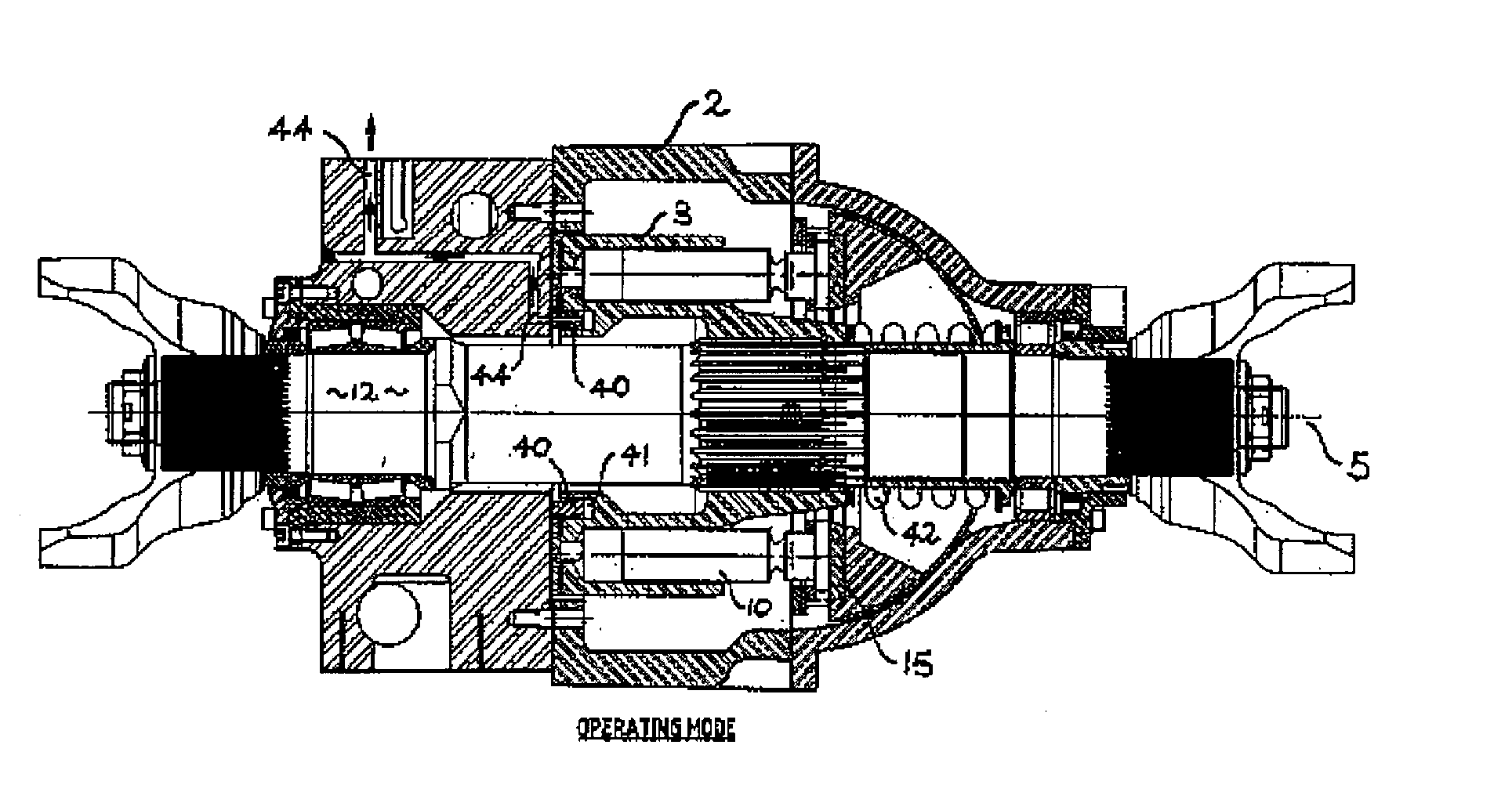

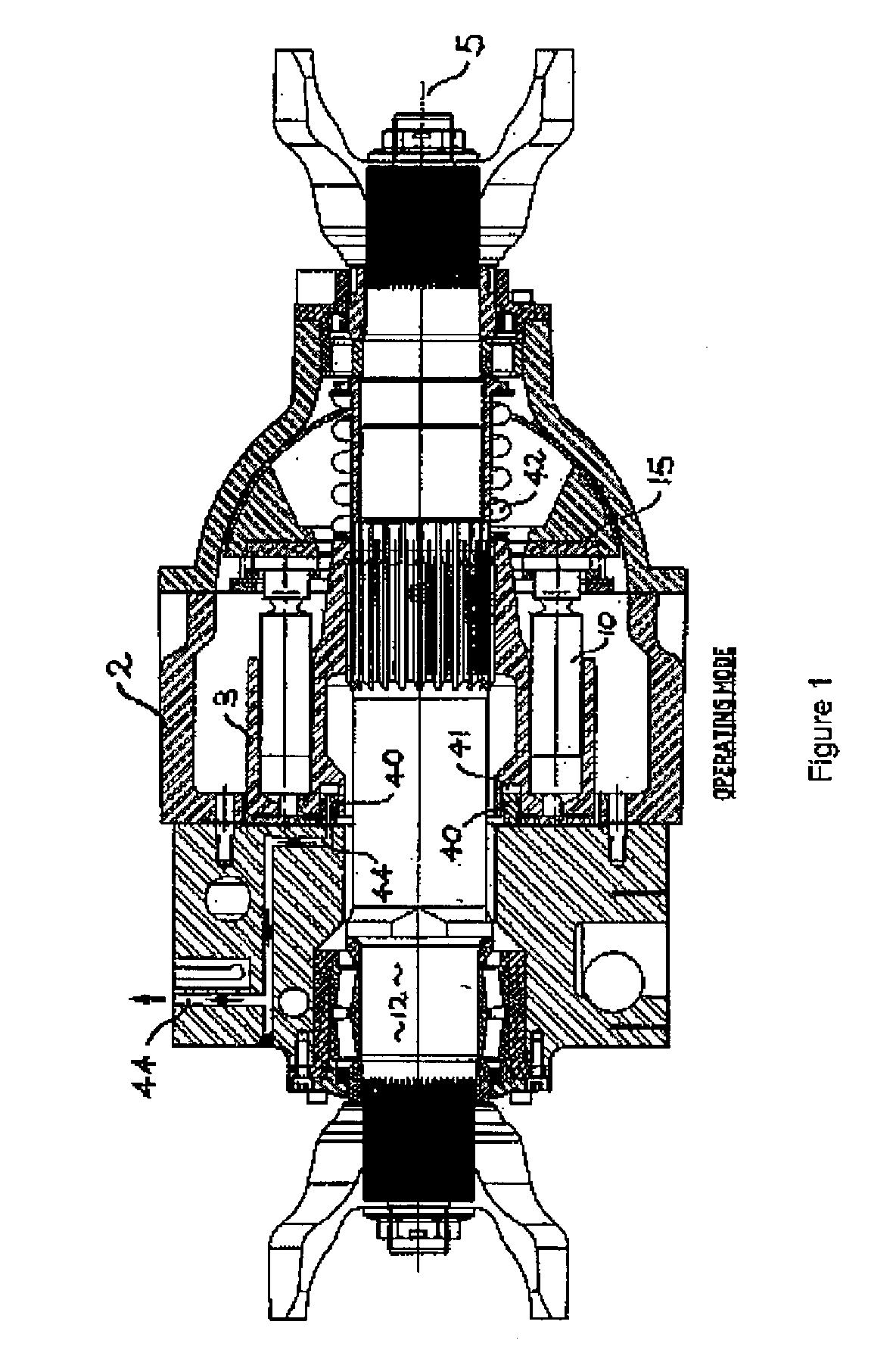

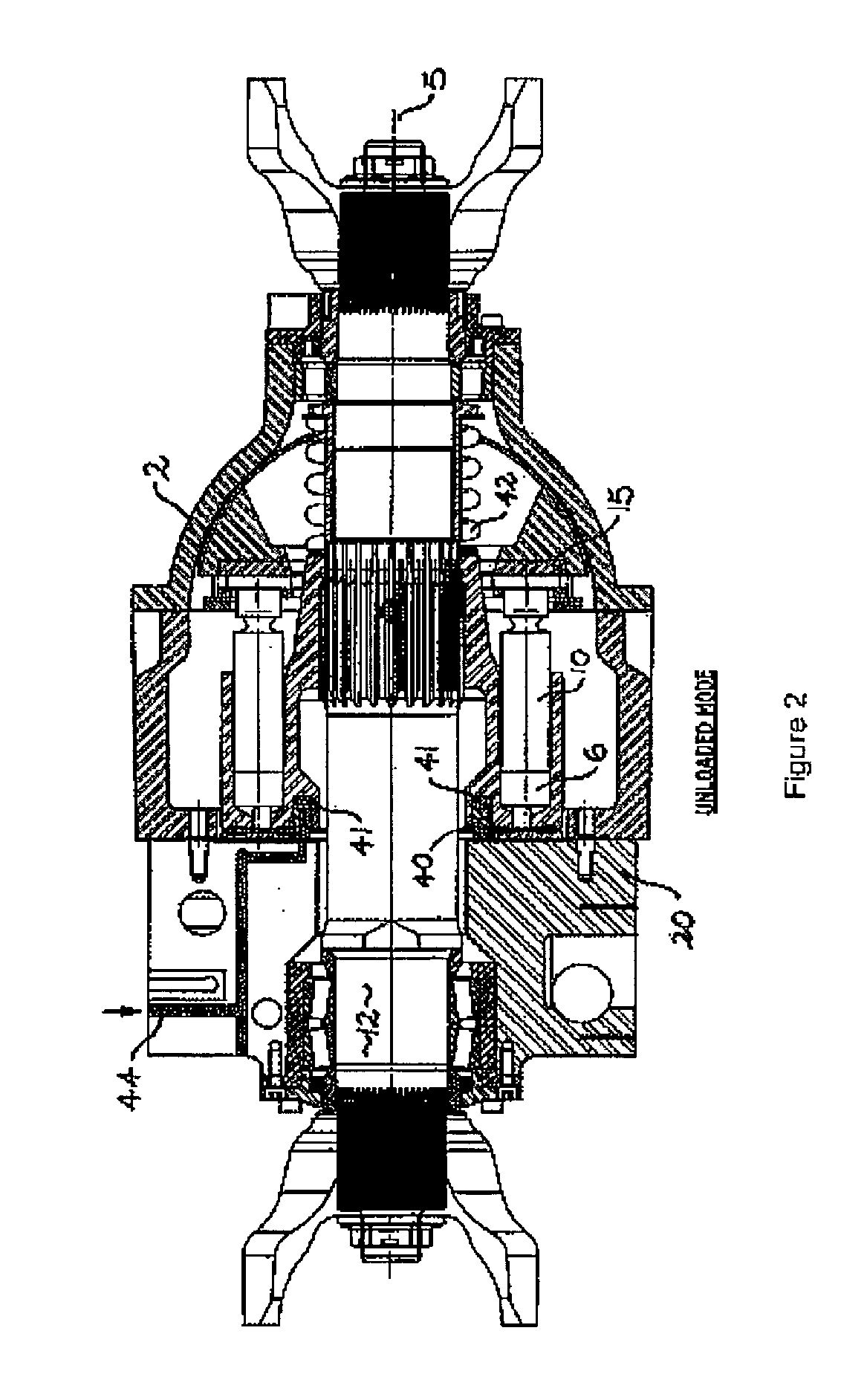

first embodiment

[0075] This active biasing mechanism is intended primarily to complement the operation of the lift-off cylinder as illustrated in the invention shown in FIGS. 1 and 2. For clarity of illustration, however, the lift-off mechanism is omitted from the embodiment shown in FIGS. 3 and 4.

[0076] Referring to FIGS. 3 and 4, the hold-down piston 30 takes the form of an annular sleeve disposed coaxially around the drive shaft, at the front (right-hand when viewing the drawings) end of the cylinder block, remote from the valve plate. The hold-down cylinder is correspondingly shaped, and is pressurised via a supply passage 35, which extends through the housing and the drive shaft as shown.

[0077] The pressure supplied to the hold-down cylinder is regulated by an electronic valve actuator 36 (represented diagrammatically in FIG. 3 only) according to predetermined operational parameters related to the pressure and flow characteristics of the pump / motor assembly and other characteristics of the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com