Engine starting apparatus

a technology of engine starting and starting gear, which is applied in the direction of engine starting, electrical control, exhaust treatment electric control, etc., can solve the problems of increased cylinder pressure, increased fuel remaining in the intake port, and insufficient atomization of fuel, so as to achieve further reduction of emissions and fuel injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0141] (Effect of Embodiment 1)

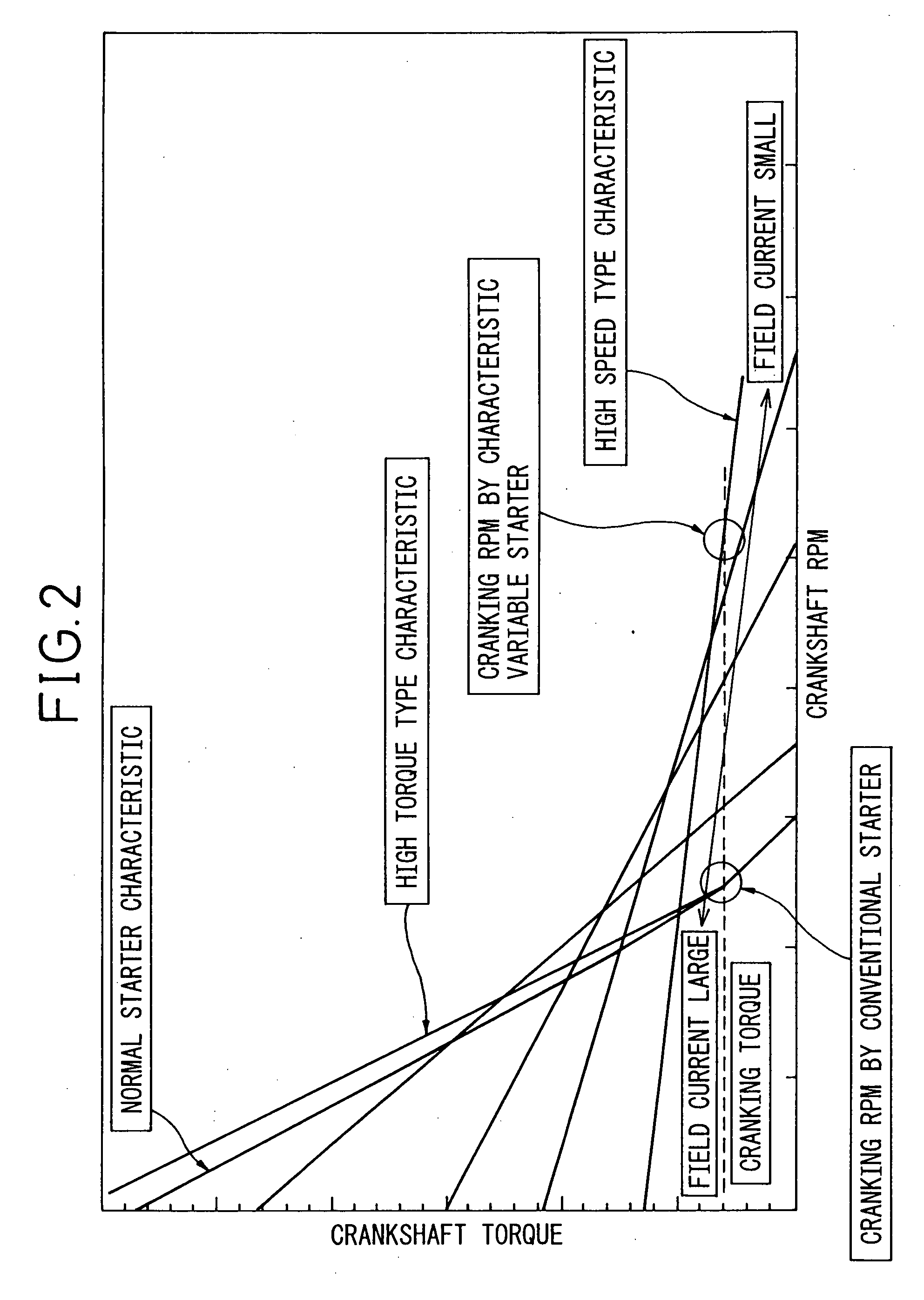

[0142] According to the present embodiment, when the catalyst is in an inactive condition, first, the engine is driven by controlling the output characteristic of the starter 1 to the high torque type (by increasing the field current), as shown in FIG. 4(a), and then, after top dead center is reached in any one of the cylinders, the output characteristic of the starter 1 is controlled to the high speed type by reducing the field current of the motor, thereby making it possible to properly drive the engine at high speed. As a result, as the engine rpm during cranking rises compared with the normal case (the case where the catalyst is in an active condition), as shown in FIG. 4(b), the amount of fuel remaining in the intake port and the cylinder decreases, and the injected fuel properly contributes to combustion. Accordingly, even when the catalyst is in an inactive condition (the purification performance is low), emissions (HC) emitted into the atmosphe...

embodiment 2

[0145] (Embodiment 2)

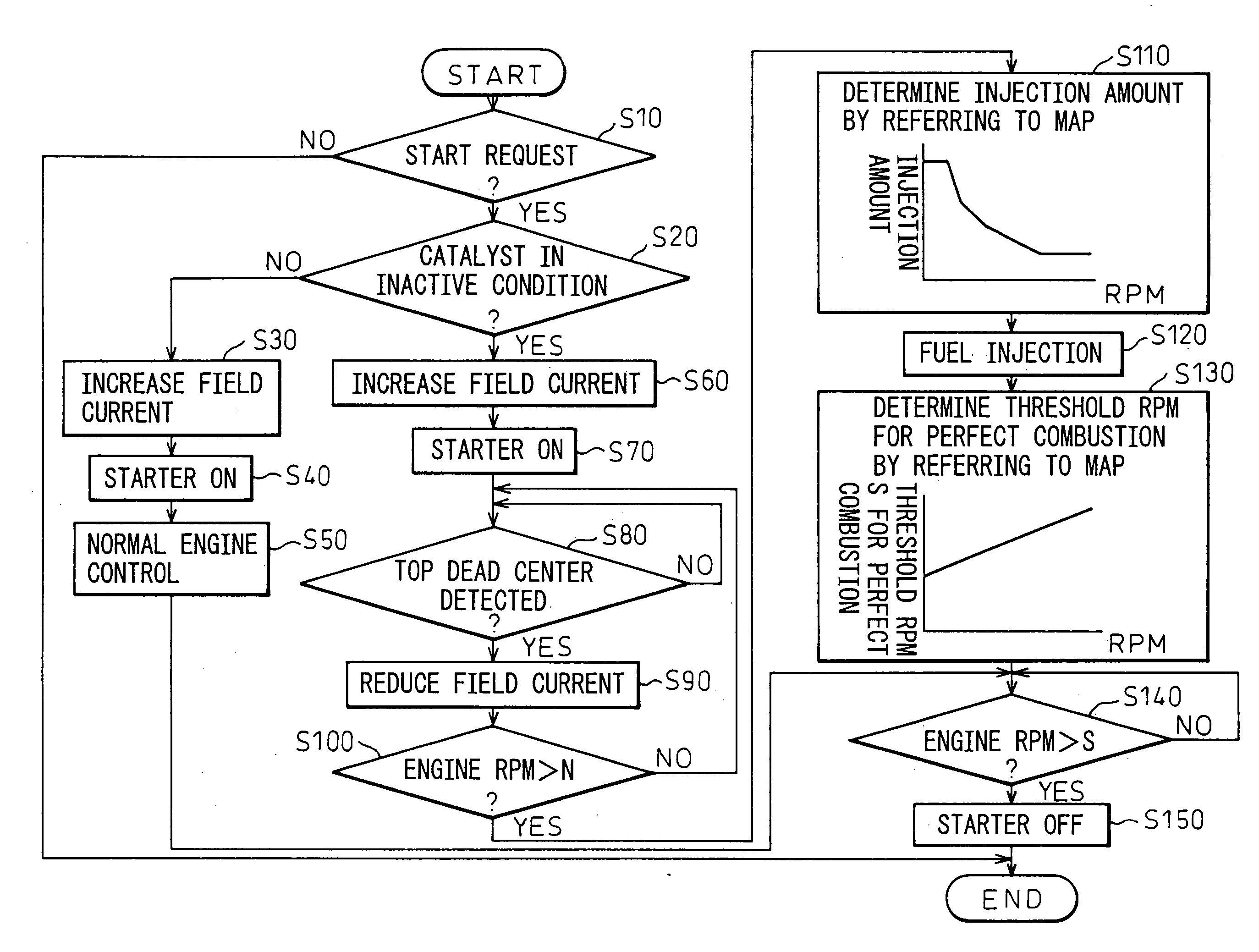

[0146] FIG. 5 is a flowchart illustrating the operation of the engine starting apparatus A.

[0147] In this embodiment, steps 80 / 90 and 100A are performed instead of the steps 80 to 100 shown in the flowchart described in the first embodiment. Otherwise, the process (steps 10 to 70 and 110 to 150) is the same as that of the first embodiment (the description will not be repeated here).

[0148] Details of the steps 80 / 90 and 100A will be described below.

[0149] Step 80 / 90: The field current of the motor is reduced compared with the normal case (the case where the catalyst is in a normal condition). More specifically, the field current is determined from the current engine rpm or starter rpm by referring to a map.

[0150] Step 100A: Decision is made as to whether or not intake manifold pressure is either equal to or higher than a predetermined value p. If the intake manifold pressure is higher than the predetermined value p (the result of the decision is NO), the process ...

embodiment 3

[0155] (Embodiment 3)

[0156] FIG. 6 is a flowchart illustrating the operation of the engine starting apparatus A.

[0157] This embodiment concerns an example, in which control of the reduction of the field current is stopped and is changed to the normal engine control.

[0158] The details of the control according to this embodiment will be described below with reference to the flowchart.

[0159] Steps 10 to 70: Same as the corresponding steps in the first embodiment (refer to the description of the first embodiment).

[0160] Step 80: The field current of the motor is reduced compared with that in the normal condition (that is, when the catalyst is in an active condition). More specifically, the field current is determined from the current engine rpm or starter rpm by referring to a map.

[0161] Step 90: The state of charge of the battery 10 is checked. If the state of charge is low (the result of the decision is NO), the field current reducing control is stopped, and the process proceeds to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com