Laminated cook-in food package

a technology of laminated wrappers and cook-in food, which is applied in the field of laminated wrappers, can solve the problems of conventional wrappers possessing a number of undesirables, the liners of paper pans cannot be conformed, and the cooking liquids to migrate under the liner and contaminate the cooking container, so as to achieve low vapor emission, low vapor emission, and low vapor emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

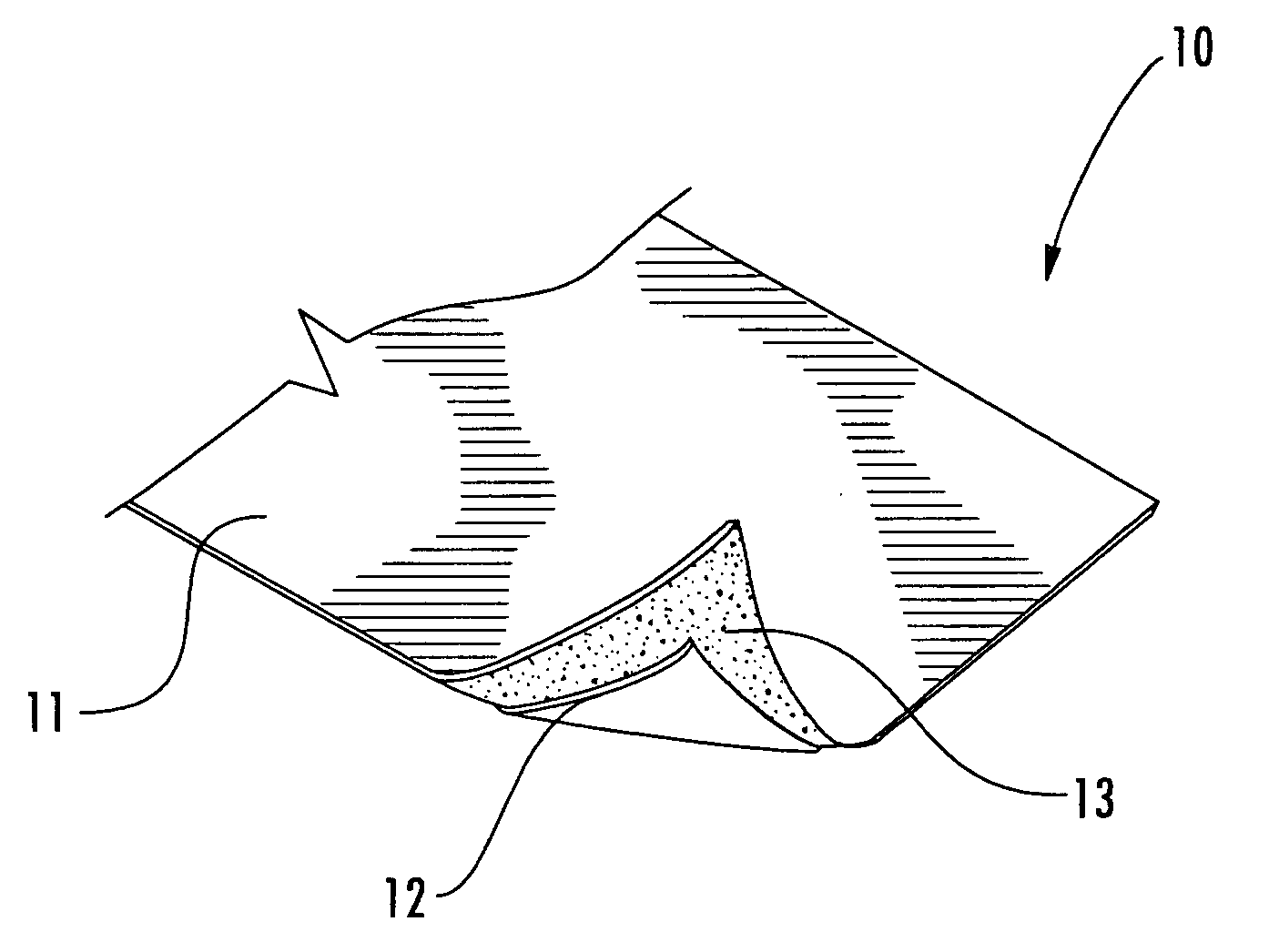

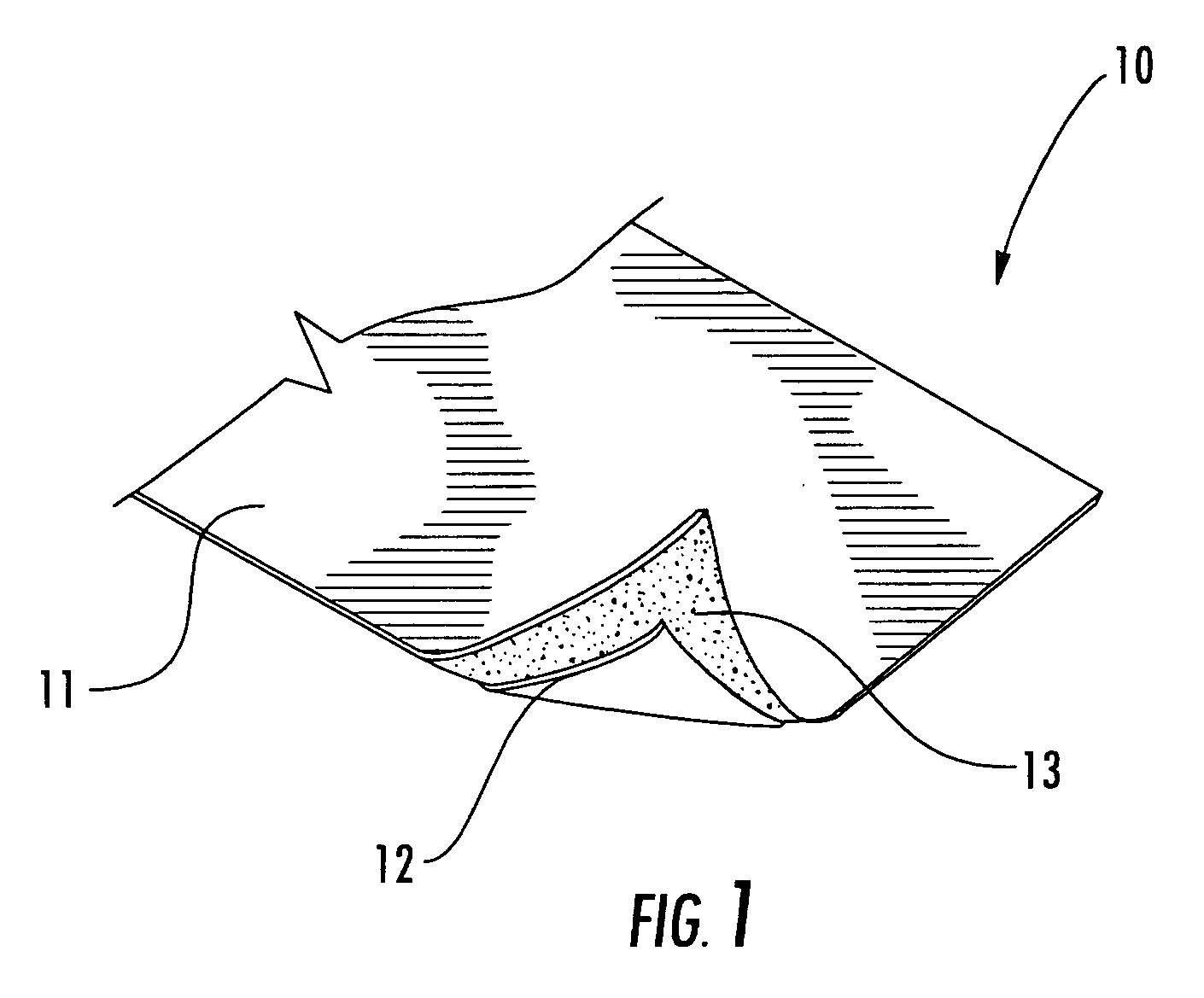

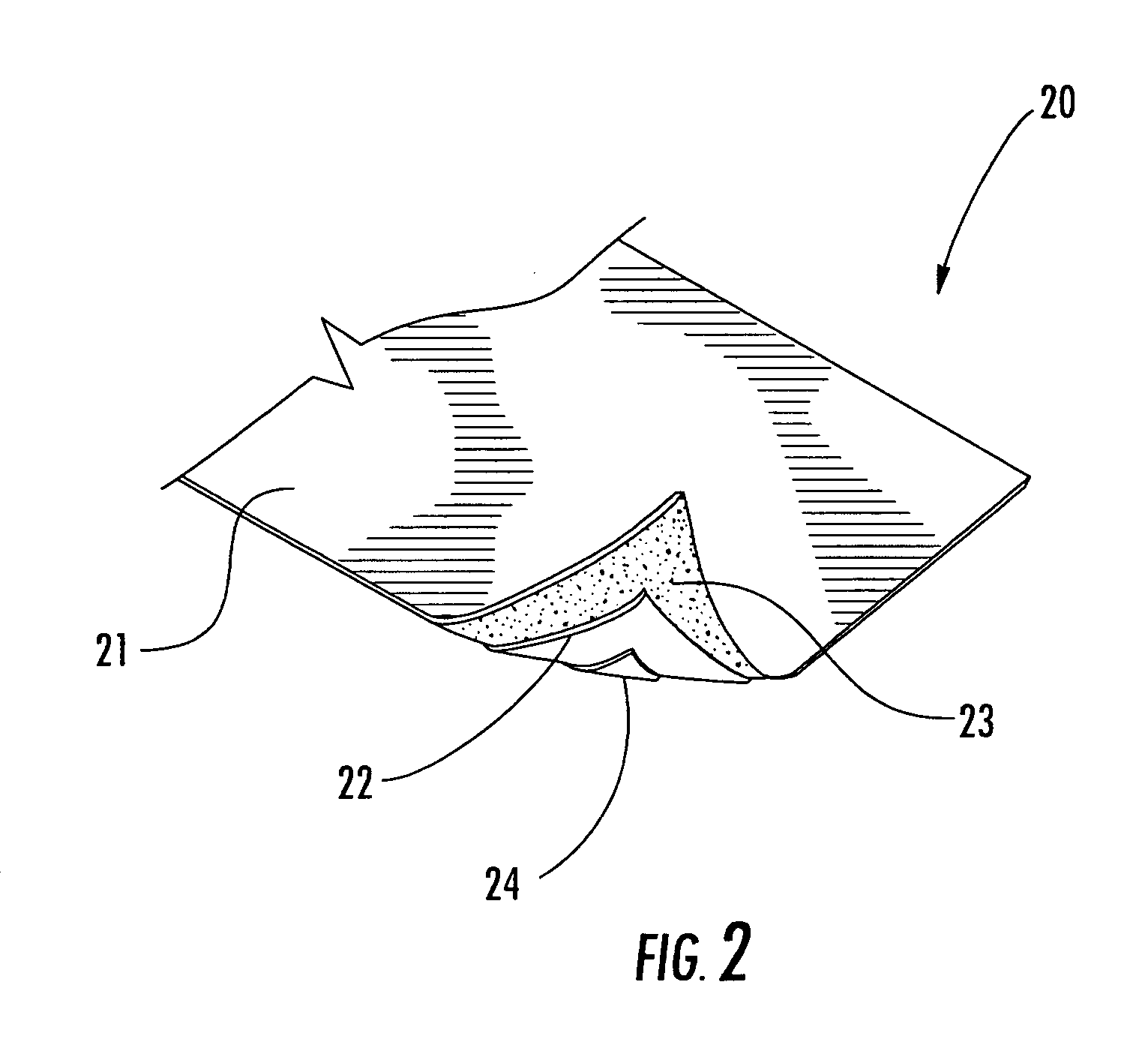

Image

Examples

example a

[0061] 24# Silicone Grease Proof (GP) paper w / wet strength was patterned and laminated to a 0.00285 mil, 12.0# Aluminum Foil (# / 3000 ft2) Aluminum Foil Laminate. A high temperature (+450 F, +232 C) acrylic adhesive was applied to the GP paper utilizing a commercial gravure coater. The adhesive coating pattern was applied in the shape of a hexagon with 1.0 centimeter per side. The laminate thus prepared was used to prepare potatoes, asparagus and chuck roast. Samples were tested as follows:

[0062] 1. Prepared: Baked Potato. [0063] Ingredients: One potato, olive oil, salt & black pepper. [0064] Packaging: Potato and ingredients placed on 15 inch square laminate cut to fit. Laminate tightly wrapped around potato, crimped and rolled at top. Cooking pouch placed in oven. [0065] Time / Temperature: 50 minutes at 400F (204C) in natural gas fired oven. [0066] Observations: No cook out. No discoloration of food. No off taste. Complete potato release from GP paper. No significant GP paper disco...

example b

[0084] 24# Silicone Grease Proof (GP) paper w / wet strength was full side laminated to a 0.00285 mil, 12.0# Aluminum Foil (# / 3000 ft2) Aluminum Foil Laminate. A high temperature (+450 F, +232 C) acrylic adhesive was applied to the GP paper utilizing a commercial gravure coater. The adhesive coating was a full side application. The laminate thus prepared was used to prepare sirloin roast. Samples were tested as follows:

[0085] 5. Prepared: Sirloin Roast. [0086] Ingredients: Large cubes of sirloin roast, garlic, onions, salt, pepper, red wine vinegar. [0087] Packaging: Laminate 20 inch square placed in baking dish. Roast and ingredients placed on laminate. Laminate tightly wrapped around roast and ingredients, crimped and rolled at top. Cooking dish filled with 2 inches of water for even heat dispersion. Cooking pouch placed in oven. [0088] Time / Temperature: 90 minutes at 400F (204 F) in natural gas fired oven. [0089] Observations: No bottom leakage. No discoloration of food. No off ta...

example c

[0092] 24# Silicone Grease Proof (GP) paper w / wet strength was full side laminated to a 0.0035 mil, 14.7# Aluminum Foil (# / 3000 ft2) Aluminum Foil Laminate. [0093] No bottom leakage. No discoloration of food. No off taste. Complete food release from GP. Foil portion of pouch does not crack or delaminate with use / handling. GP remained intact and did not leak. The product dead folds adequately, and adequately seals a casserole dish, hand pattern a tray, or produce a cooking pouch.

[0094] Based on the foregoing examples, an aluminum foil layer 0.0035 mil, 14.7# Aluminum Foil (# / 3000 ft2) or heavier provides improved strength and dead fold at minimum foil weight. Layer weights used for standard commercially available aluminum foil 0.0065 mil, 27# Aluminum Foil (# / 3000 ft2) or heavier can be laminated and will perform equally well in use testing. The economics favor the use of a lighter weight 0.0035 mil, 14.7# Aluminum Foil (# / 3000 ft2) layer.

[0095] Numerous variations can be made on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com