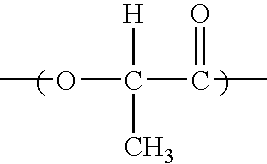

Fibers comprising starch and biodegradable polymers

a biodegradable polymer and fiber technology, applied in the field of environmental degradation-friendly fibers comprising starch and biodegradable polymers, can solve the problems of less commercial success, compositions with excellent degradability only limited processability, compositions which are more easily processable, etc., and achieve the effect of high attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 4

[0110] In light of the findings in Comparative Example 3 and the weakness of these fibers, a different blend composition for compounding was utilized. A 50 / 50 solution of starch in water at 90° C. was used. The starch was allowed to soak in the water until fully dissolved and the solution was clear. This starch solution was mixed in an amount equivalent to 50 parts solid StarDri 100, along with 12 parts amorphous PLA, 37 parts semi crystalline PLA and 10 parts glycerin. It was noted that this blend did not exhibit any granular structure consistent with starch that has not been fully destructured. The blend was compounded as follows: the high melting temperature semi-crystalline PLA (Tm≈170° C.) was added to the twin-screw mixer at 210° C. for 5 minutes until completely mixed. The temperature was then decreased to 130° C., at which time the starch solution and glycerin was added and the water vapor flashed off. Once the vapor was flashed off, the amorphous PLA was added and the mixtu...

example 5

[0113] The blend was compounded as in example 3 with 74 parts amorphous PLA, 24 parts StarDri 100 and 6 parts glycerine. The properties are in Table 1.

example 6

[0114] The blend was compounded as in example 3 with 27 parts PLA, 64 parts StarDri 100 and 9 parts glycerine. The properties are in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com