Carbon nanotube structure, method of manufacturing the same, carbon nanotube transfer body, and liquid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

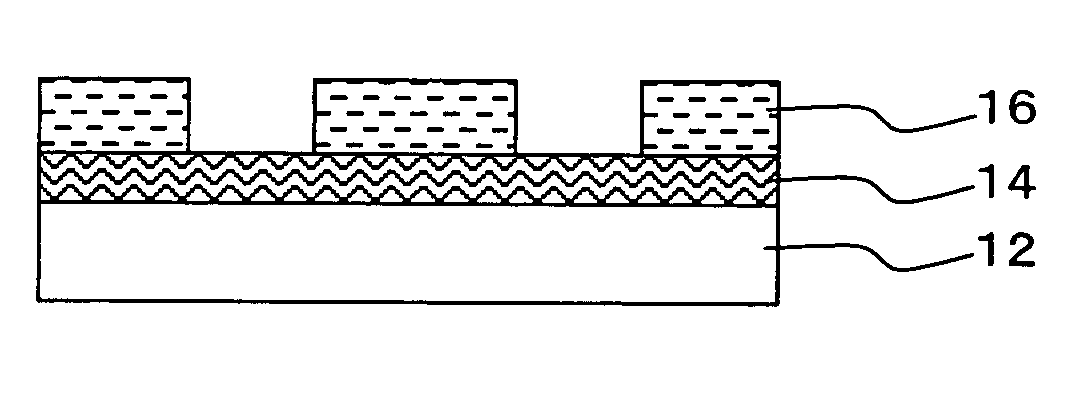

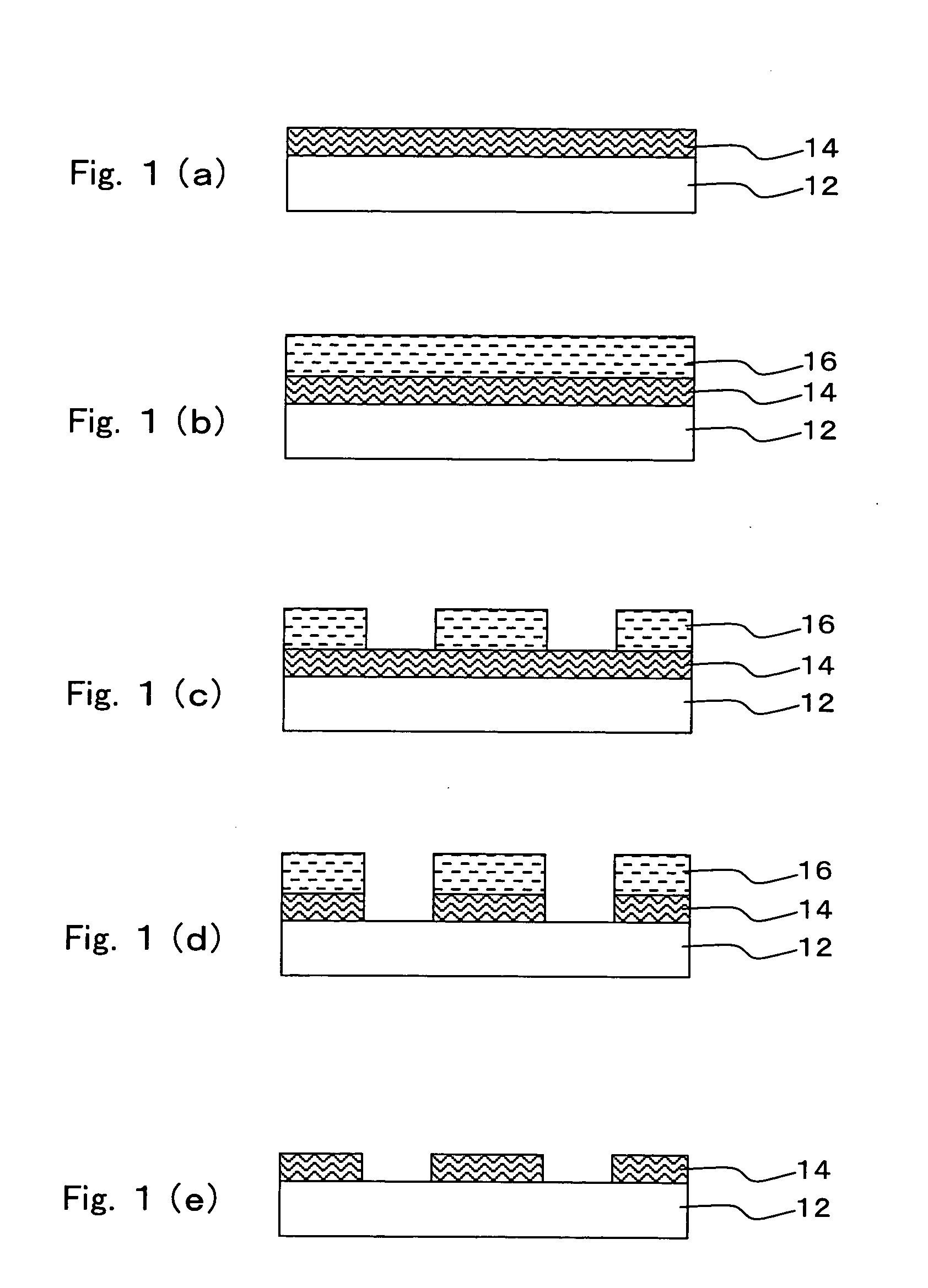

Image

Examples

example 1

Multi-Wall Carbon Nanotube Carboxylic Acid Anhydride Coating Material, Synthesis of a Coat

(Addition Step)

Addition of Carboxyl Group . . . Synthesis of Carbon Nanotube Carboxylic Acid

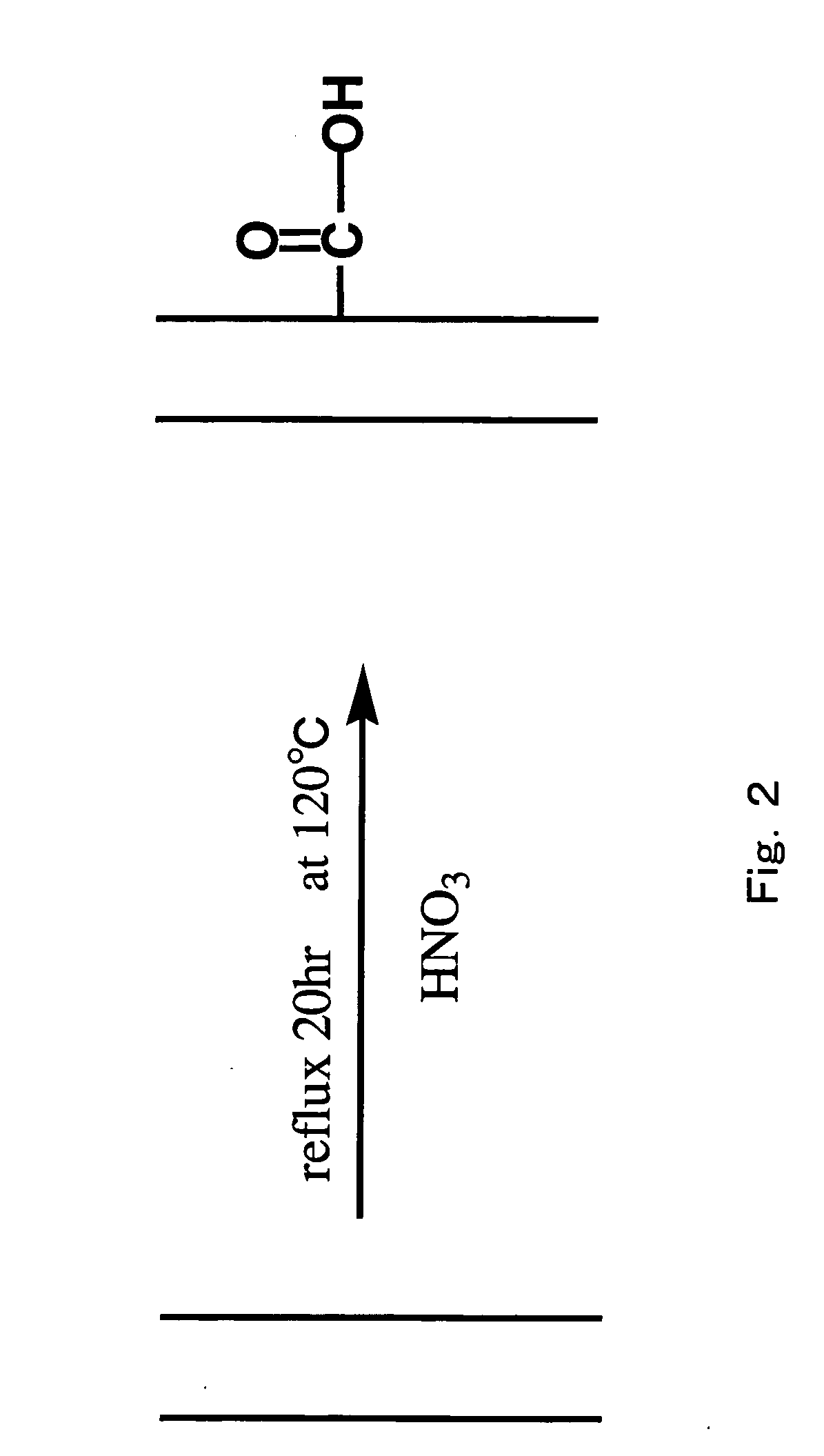

[0195] 30 mg of multi-layer carbon nanotube powder (purity: 90%, average diameter: 30 nm, average length: 3 μm, a product of Science Laboratory Inc.) was added to 20 ml of concentrated nitric acid (a 60% by mass aqueous solution, a product of KANTO KAGAKU) for reflux at 120° C. for 20 hours to synthesize carbon nanotube carboxylic acid. A reaction scheme of the above is shown in FIG. 2. In FIG. 2, a carbon nanotube (CNT) is represented by two parallel lines.

[0196] The temperature of the liquid solution was returned to room temperature and centrifuged at 5, 000 rpm for 15 minutes to separate supernatant liquid from precipitate. The recovered precipitate was dispersed in 10 ml of pure water, and the dispersion liquid was subjected to centrifugal separation at 5,000 rpm for 15 minutes to separate supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com