Method and system for preventing clathrate hydrate blockage formation in flow lines by enhancing water cut

a technology of clathrate hydrate and flow line, which is applied in the directions of transportation and packaging, separation processes, organic chemistry, etc., can solve the problems of self-limiting hydrate formation, achieve simple, cost-effective, and environmentally friendly strategies, and enhance the water cut of hydrocarbon containing fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

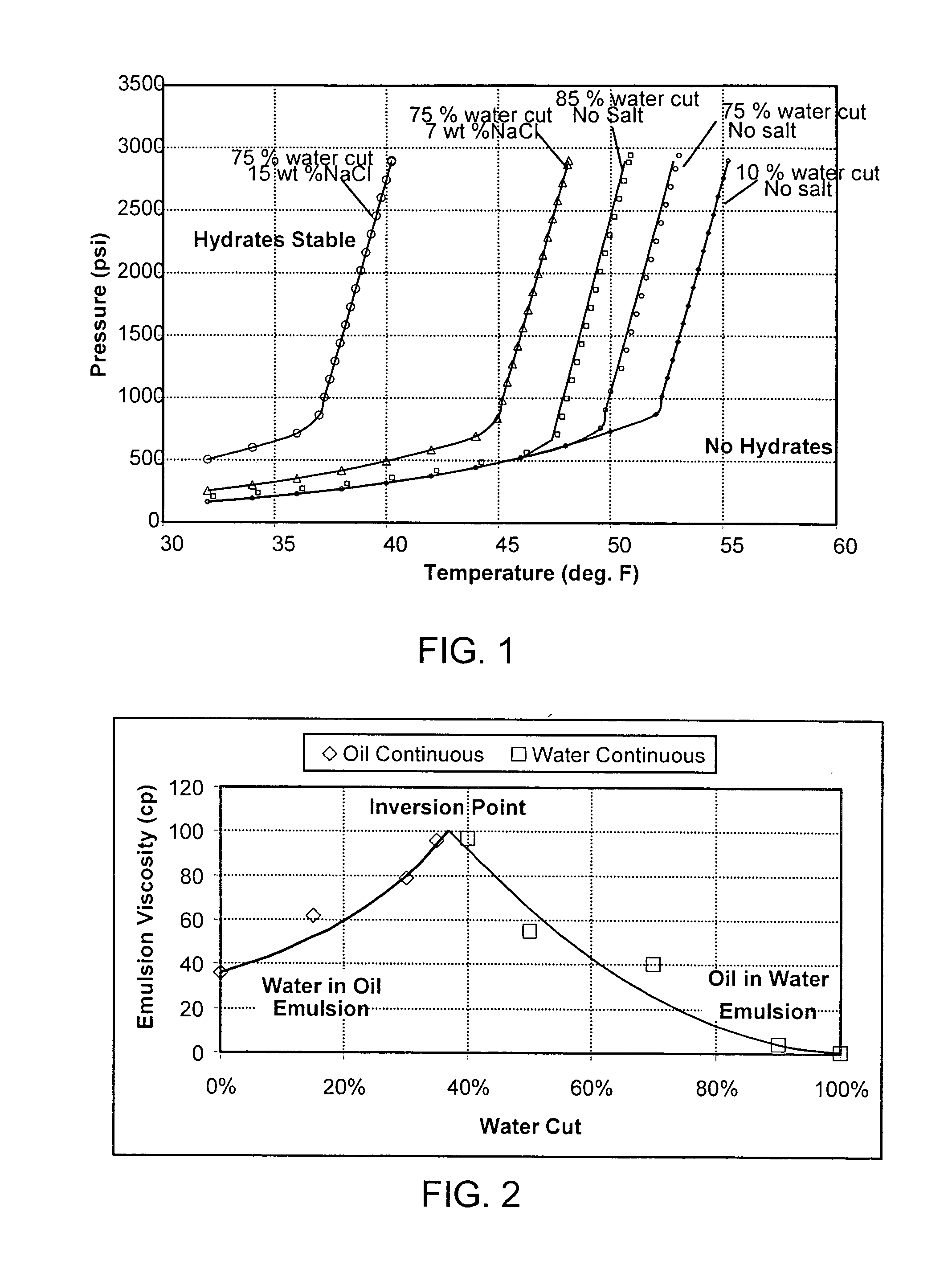

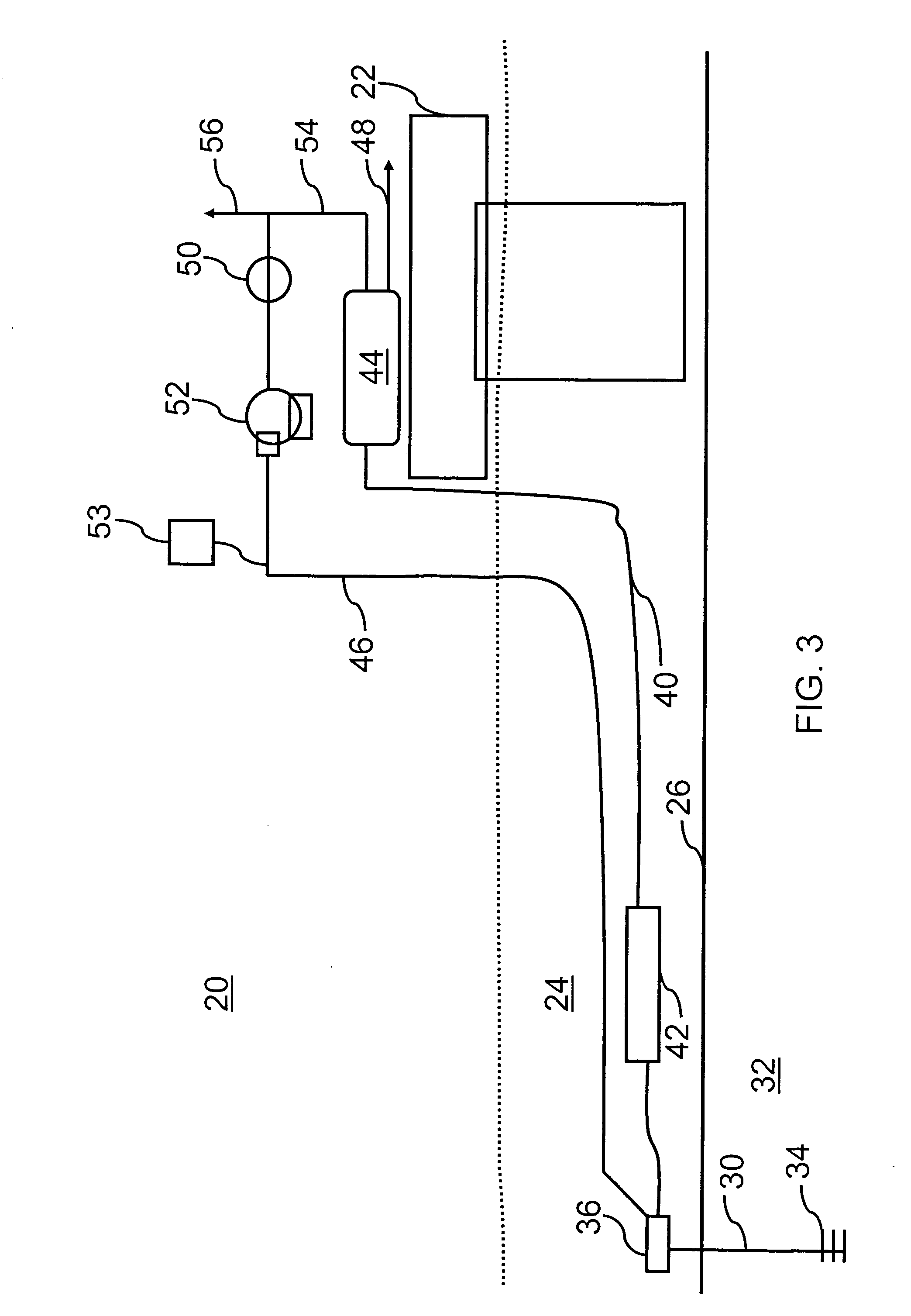

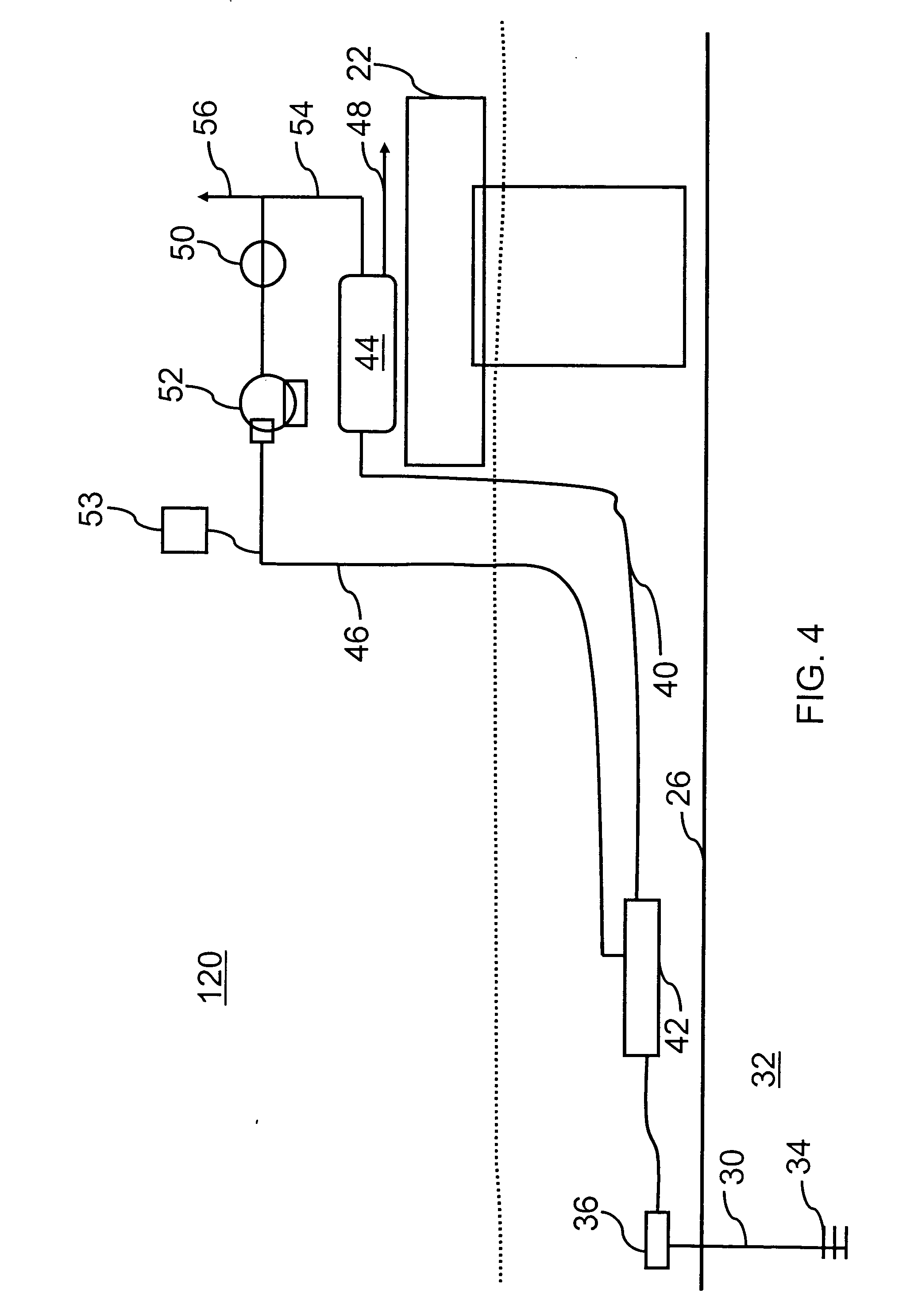

[0024] The present invention is counterintuitive and surprising in that it calls for adding excess water to a hydrocarbon containing fluid to inhibit hydrate blockage formations in flow lines of a system. Conventional wisdom is to remove water and / or add chemical hydrate inhibitors. This process of purposely adding water, which is abundantly available in offshore operations, may be a cost-effective, reliable hydrate blockage inhibition strategy with several potential additional side benefits. The present invention may also be used on land as well to inhibit hydrate formation blockages where hydrocarbon containing fluids are transported along a flow line exposed to cold temperatures.

[0025] This invention applies to multiphase flow systems where formation of hydrate plugs or other significant hydrate obstructions in flow lines are a concern. Ideally, water, and possibly salt or brine, is added to a hydrocarbon containing fluid such that a water continuous phase is present (high water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrate equilibrium temperature | aaaaa | aaaaa |

| hydrate equilibrium temperature | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com