Self-venting microwave cooking container for use with a vertical fill automated machine

a technology of automatic machine and cooking container, which is applied in the field of cooking containers, can solve the problems of microwave ovens not evenly distributing heat to the product being cooked, food can become soggy and undesirable, and the overall cost of producing the container is reduced, and the heating is more consistent. the effect of reducing the amount of material thrown away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

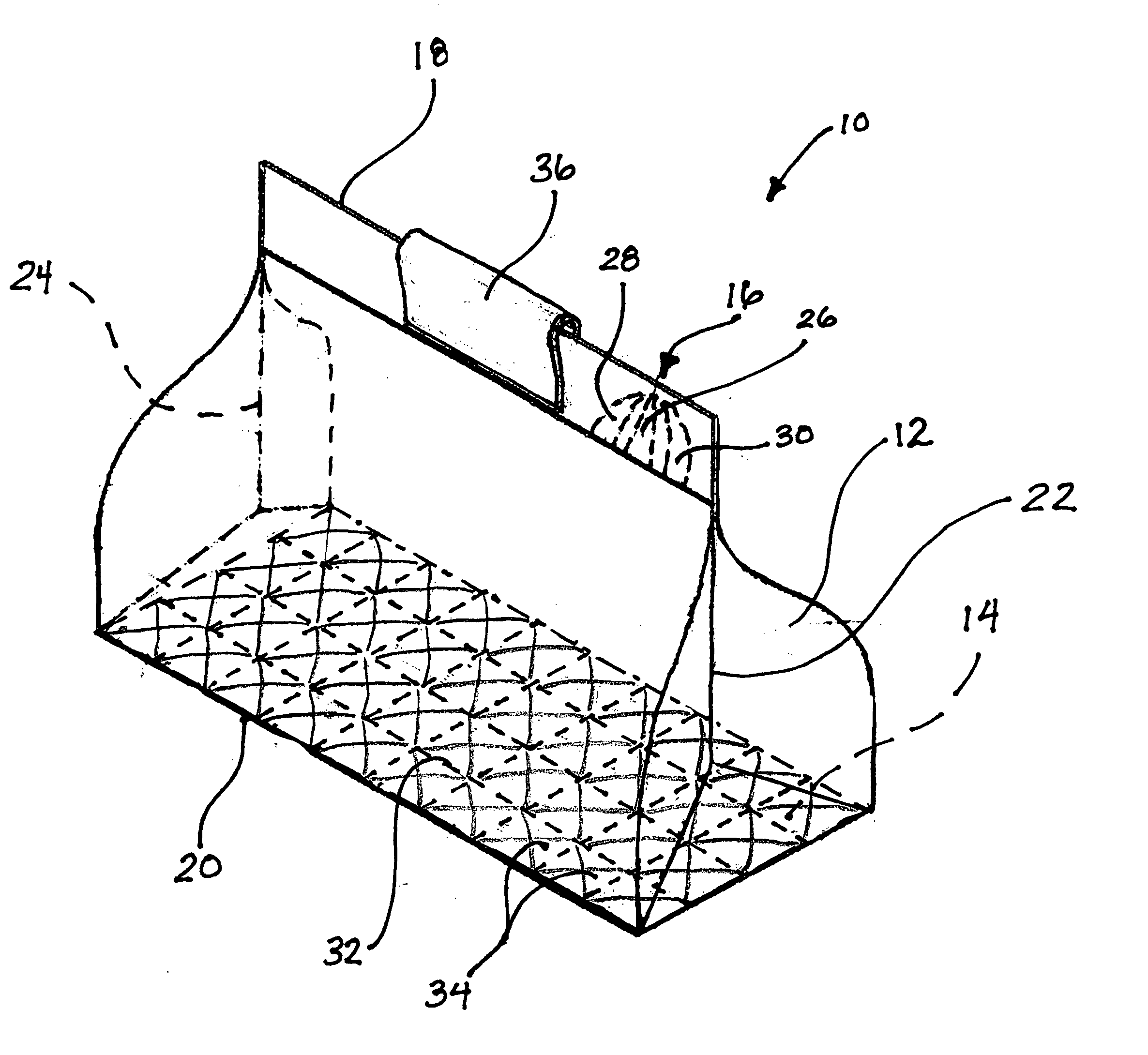

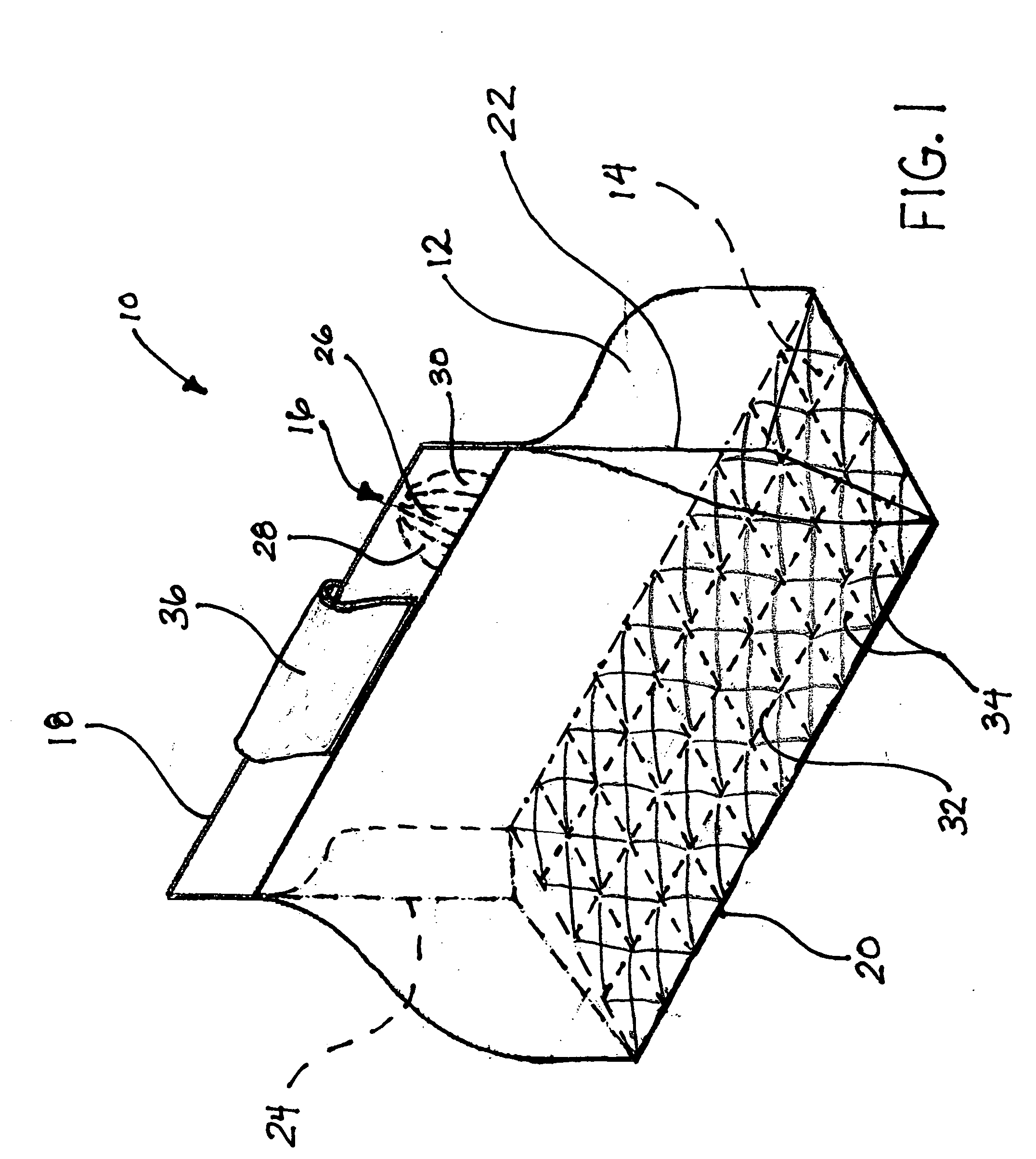

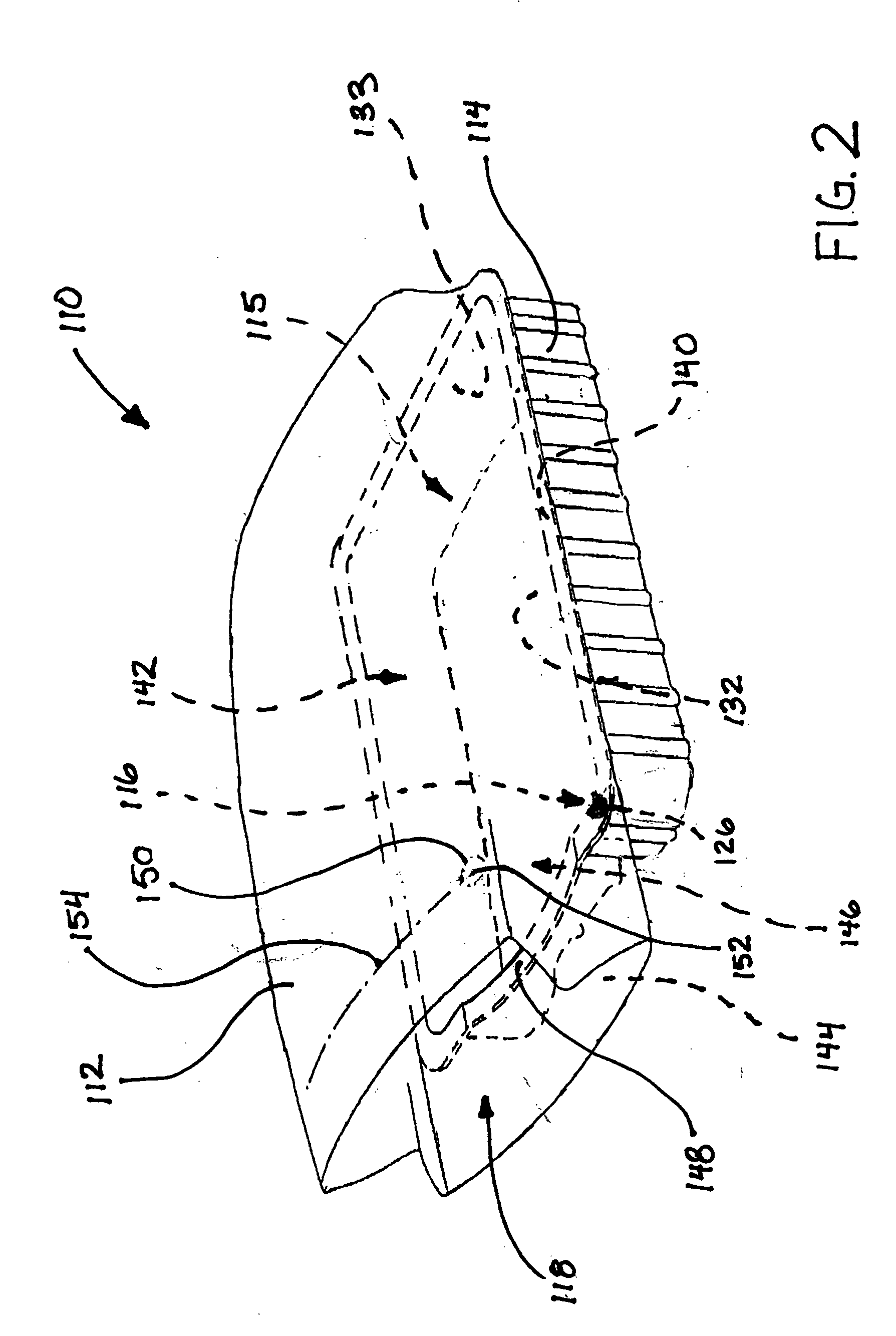

[0017] The present invention is a self-venting microwave cooking container for use with a vertical fill automated machine. With reference to FIG. 1, an exemplary embodiment of a microwave cooking container 10 made in accordance with the present invention generally includes a bag portion 12, a tray portion 14, and a venting configuration 16. In this exemplary embodiment, the bag portion 12 is constructed from a polypropylene film, but could certainly be constructed from other materials (e.g., retortable film or succeptor film) without departing from the spirit and scope of the present invention. Similarly, in this exemplary embodiment, the tray portion 14 is made of a more rigid, food-grade polypropylene, but could also be constructed from other materials (e.g., cardboard) without departing from the spirit and scope of the present invention.

[0018] The bag portion 12 generally defines an opening 18 for receiving food product and a floor 20 for receiving the tray portion 14. In the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com